Simulation Study and Sensitivity Analysis of Gamma-Valerolactone Production from Ethyl Levulinate

DOI:

https://doi.org/10.37934/arfmts.97.2.186196Keywords:

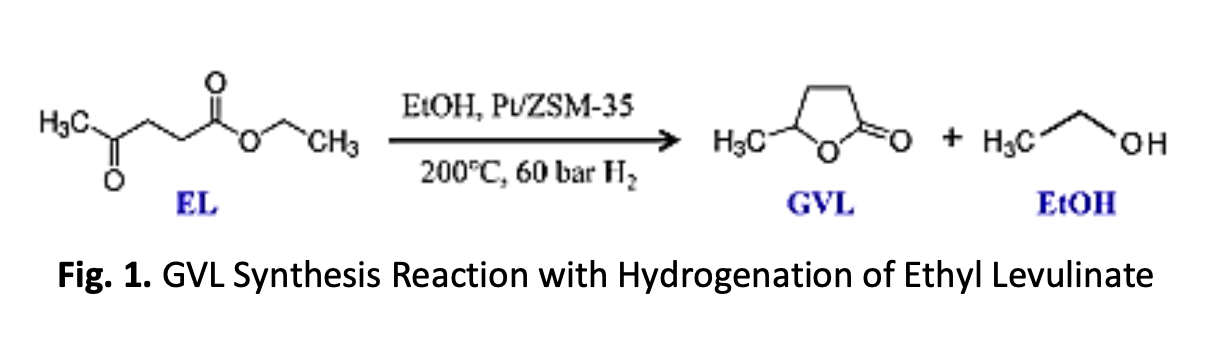

Gamma-valerolactone, biomass, hydrogenation, Ethyl Levulinate, NRTLAbstract

Gamma-valerolactone (GVL) is emerging as a promising renewable fuel because it can be produced from renewable materials such as biomass. This article presents a conceptual design and simulation of the conversion of ethyl levulinate into GVL biofuel by hydrogenation process using ChemCAD 7.1.2 software. The process simulation method involves selecting a thermodynamic model, defining component chemicals, selecting suitable operating units and identifying operating conditions. The NRTL thermodynamic model was used for the liquid phase modeling and SRK for the vapor phase fugacity calculation. The binary interaction parameter of NRTL thermodynamic model was regressed from experimental vapor-liquid equilibrium (VLE) data. A sensitivity analysis of the effect of feed temperature on the GVL purification distillation column was carried out to obtain the optimum value for the distillation column configuration.

Downloads