Drying Droplets: A Review on its Numerical and Experimental Studies to Remove Coffee Ring Effect

Keywords:

Numerical evaluation analysis, coffee ring effect, substrates, hard diskAbstract

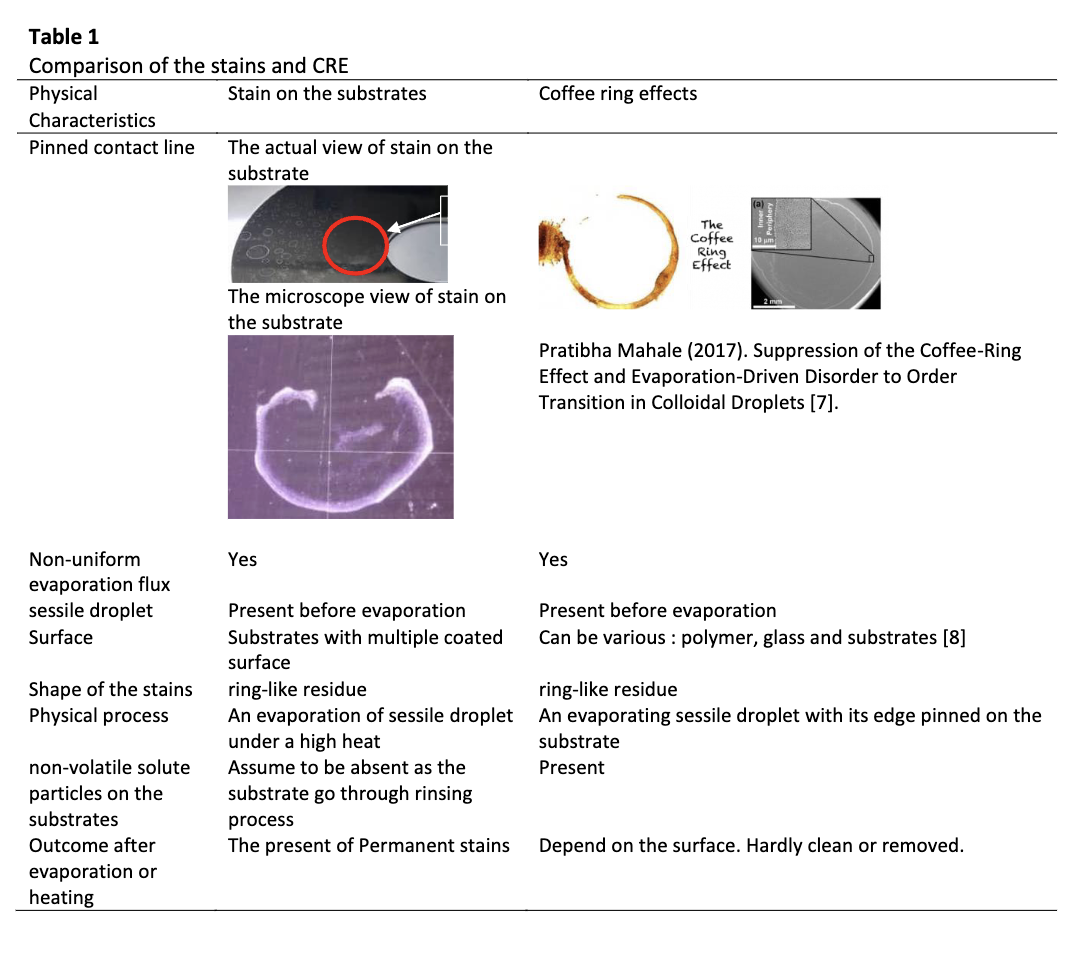

It is widely known that significant rejection percentage of substrates in the hard disk manufacturing industry is due to the stain appeared during drying of cleaning solution after platting process. Comparison of the characteristics and the causes of these stains suggested that the study of coffee ring effect (CRE) and droplets analysis are needed before any further analysis is carried out. In this review on CRE and droplets, both numerical and experimental works were critically analyzed. Previous studies have highlighted that the drying process of the water droplets are affected by the properties of the water droplets, substrate and temperature. Manipulation of Constant Contact Angle, Constant Contact Radius, advanced contact angle and receding contact angle by varying the arrangement of the substrates and the position of the drying equipment is required to attain the optimum setup to eliminate CRE. Furthermore, manipulation of the temperature of the substrates can enhance the drying process of the droplets before the formation of CRE but the process must not change the properties of the substrates. CRE formation also depends on the properties of the substrates and water droplets. Changing the chemical properties substrates are not advisable to eliminate CRE due to its complex design of the substrates for data storing. All the numerical tests have to be performed according to correct procedures to ensure accurate and acceptance by the industries. Verified and validated results from the evaluation will help to accurately predict the real consequences for further optimization. Knowing that the formation of CRE is caused by the evaporating of the water droplets, we need to find ways to eliminate the formation of water droplets before the heating process, in order to eliminate CRE.

Downloads