Effect of Various Concentrations of Sodium Hydroxide/Hot Alkali Treatment on the Physical Properties of Ramie Fibres

DOI:

https://doi.org/10.37934/arfmts.115.2.96102Keywords:

Ramie, biodegradable, hot alkali, sodium hydroxide, sedimentationAbstract

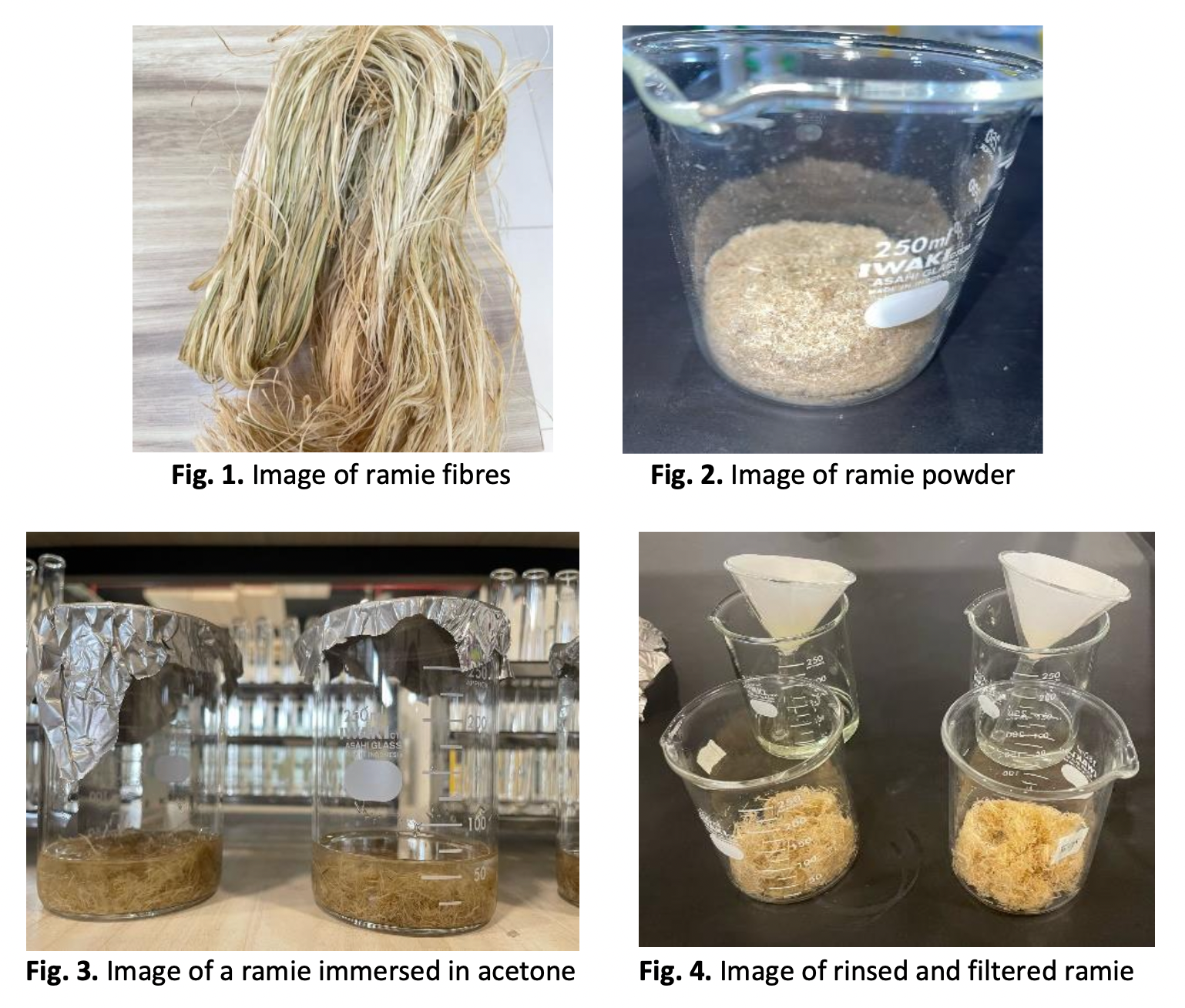

The preparation stages that precede the final treatment with a chemical treatment like alkali determine the physical characteristics of ramie fibres. It modified the hydroxyl group which is responsible for the hydrogen bonding of the fibres. This work examined the pre-treatment of ramie fibres with acetone followed by alkali or hot alkali with various concentrations. The immersion of ramie fibres in certain percentages of sodium hydroxide solution resulted in a good performance of their physical characteristics. The ramie fibres treated with 10% NaOH exhibit the best dispersion stability and low agglomeration or precipitation in water with an amount of 14%. When alkali is applied to ramie fibres, the hydrophilic group on their surface grows, potentially improving the fibre's capacity to absorb water. However, when the concentration is increased to 15%, the dispersion stability of sodium hydroxide performs less well. The fibres' ability to absorb water was diminished and they became brittle due to a high alkali content. In addition to the aforementioned characteristics, the properties of precipitation and water absorption were unaffected by the hot alkaline process for all samples. The hot alkali process (80°C) was not able to generate a further breakdown of hydrogen bonds of the fibres.

Downloads