Vortex Control Using Plate Type Floor Splitter in Pump Intake

DOI:

https://doi.org/10.37934/arfmts.100.1.8997Keywords:

Anti-vortex device, single plate floor splitter, twin plate floor splitterAbstract

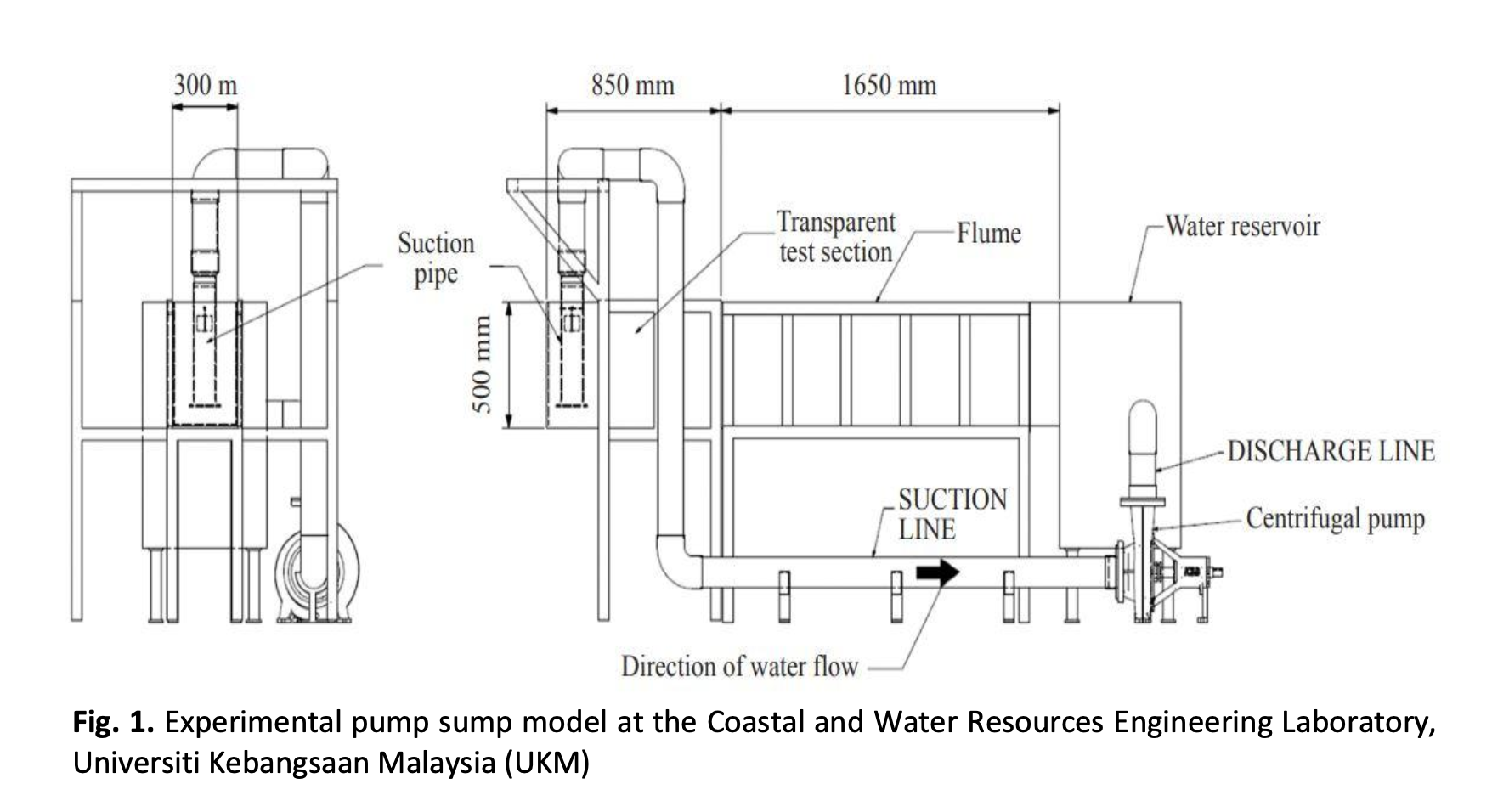

Pump sump design is very crucial in ensuring a minimum requirement for its operation. Improper pump sump design will influence the development of vortices and swirls that can adversely affect the pump efficiency which subsequently could damage the pump. This can be mitigated by installing an anti-vortex device (AVD) beneath the intake pipe in the pump sump. The AVD works by suppressing the development of vortices and swirls in the flow of water into the intake pipe. ANSI/HI 9.8-2012 standard has outlined various AVD shapes and concepts that can be used. This experimental study was conducted to determine the appropriate parameters and configurations of twin plate floor splitter (TPFS) to suppress the development of vortex in the intake pipe. Geometries and other outlines in experiments were based on the guidelines by ANSI/HI 9.8-2012. The AVD model variations used were models with no floor splitter, single plate floor splitter (SPFS), and TPFS with 25 mm, 45 mm and 65 mm gap variations. The results showed that the distance between the two sides of twin plate affects the number of vortex generation and the swirl angle reduction. The number of vortices increased with the distance between the plates but with lower localized vortex intensity. However, the TPFS models that were used produced a swirl angle of less than 5° with the 25 mm variation producing the lowest swirl angle of 2.41°. The use of TPFS shows significantly improved performance in swirl angle reduction and vortex suppression as compared to no AVD case.

Downloads