The Impingement Flow Study on the Temperature Profile Perforated Plate

DOI:

https://doi.org/10.37934/arfmts.94.2.4760Keywords:

Perforated plate, impingement jet, hot air impingement, staggered hole, tandem holeAbstract

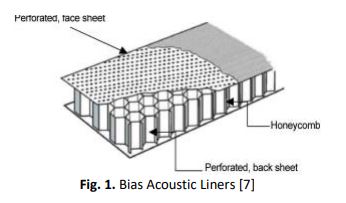

This paper presents the impingement flow study on the temperature profile perforated plate. Icing is one of the most hazardous threats in aviation and this leads to unsafe flight conditions. Hence, thermal anti-Icing is very much useful in aircraft to prevent ice accretion on the surface. On the other hand, the hotspot temperature of this technique might destroy the Aluminum-based Bias Acoustic Liner (BAL) plate. Thus, it is highly essential to study the hotspot temperature profile on the perforated plate. This study is concerned with a numerical study of the convective heat exchange between an impinging air jet at temperatures of 70 °C and a structured perforated surface using the Fluent tool. The model is designed in an Aluminium plate with the dimensions of 100 mm x 100 mm x 1mm containing 0.15 cm diameter perforated hole. In addition, the 0.25 cm diameter circular nozzle is maintained at a constant jet-to-target distance of 3.71 cm. In this sense, the standard k-ω turbulence model jet equation is applied to this three-dimensional domain with periodic boundary conditions for the Reynolds numbers ranges from 2000–9000. The simulations are performed based on the gap between two holes and the hole configuration (tandem and staggered) at different jet velocities. The simulation results reveal that there is a rapid increment in heat transfer with Reynolds number and the maximum local Nusselt number decreases by seven and increases to 24 when the Reynolds number varies from 2508.17 to 8778.588 at the surface of the perforated plate. The findings of the hole arrangement on the perforated plate indicate that the tandem hole configuration without a center hole is highly recommended for bias acoustic liners than the staggered configuration. Since the tandem hole arrangement has higher dimensionless temperature, a thicker high temperature layer will be developed at the outer surface. Hence, this kind of perforated plate is more suitable to prevent ice accretion in aircraft applications.

Downloads