Effect of Inlet Air Humidity Control on a Novel Indirect Condensative Cooling Performances in Achieving Air Thermal Comfort

DOI:

https://doi.org/10.37934/arfmts.106.2.1421Keywords:

Novel indirect condensative cooling system, air humidity control, air thermal comfort, cooling efficiency, condensation rateAbstract

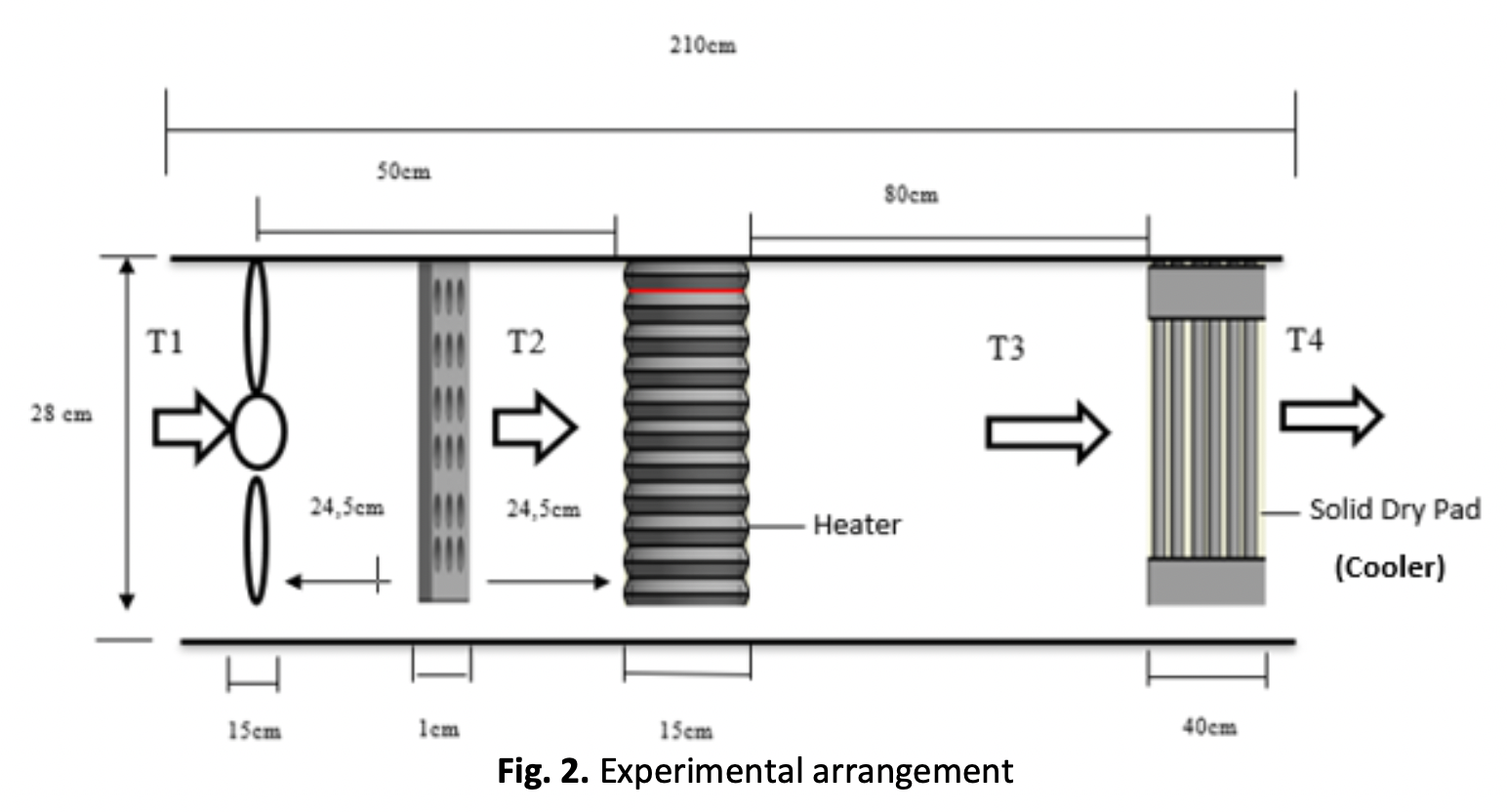

The objective of this research is to investigate the effect of controlling inlet air relative humidity on the performance of solid dry pad based indirect condensative cooling (SDP-ICC) system, in an effort to have a better air thermal comfort. The main evaporative cooling parameter such as cooling efficiency, cooling capacity, and temperature drop, condensation rate and energy efficiency ratio would be observed, together with the final dry and wet bulb air temperature and relative humidity in respect to reach the standard air thermal comfort. During the experiment test, the inlet air would be heated respectively using 1.0 kW, 1.5 kW and 2.0 kW heater in a climate chamber before it passed through to the solid dry pad, to be cooled indirect condensatively. The air velocity would be set on 11.3 m3/. The test results indicate that to achieve an air thermal comfort significantly in the evaporative and or condensative cooling system, the air should need to be treated with more than one thermal process, rather than cooling only. In this research, the SDP-ICC has only achieved the air thermal comfort in respect to its relative humidity of 67.3%, 55.65% and 44.3% respectively for heating capacity of 1.0 kW, 1.5 kW and 2.0 kW. The highest SDP-ICC cooling performance has been achieved on 1.5 kW heating capacity, in which it has reached 1.9 kW, 1.83, 3.4oC and 0.237 m3/hr respectively for cooling capacity, energy efficiency ratio, temperature drop and condensation rate. It can be concluded that by heating the inlet air relative humidity in evaporative and or condensative cooling system, it can be resulted the product air which has met the standard air thermal comfort.

Downloads