Heating Techniques of Shape Memory Alloy (SMA) - A Review

DOI:

https://doi.org/10.37934/arfmts.99.2.207220Keywords:

Shape Memory Alloy (SMA), Nickel Titanium, induction heating, thermomechanical, stress, temperatureAbstract

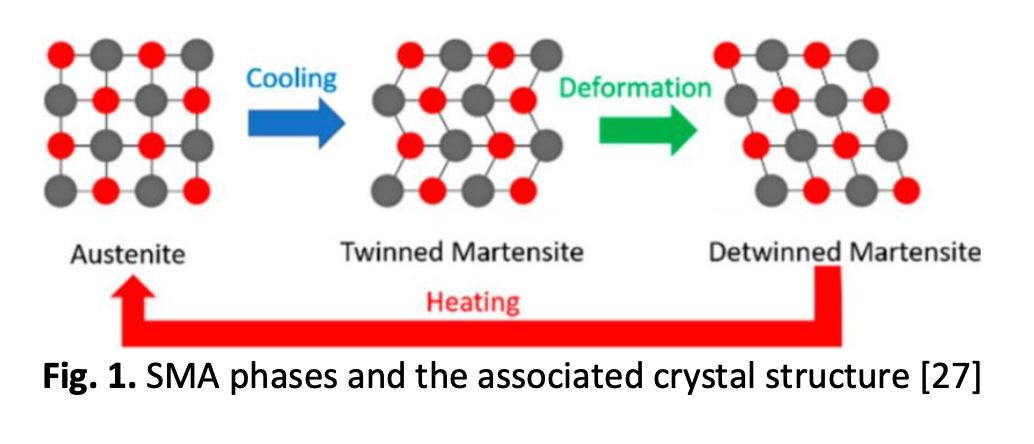

Shape Memory Alloy (SMA) possess memory capability to revert its original shape when exposed to load or temperature changes. This unique thermomechanical property occurs during solid state phase transformations which corresponds to functional properties of SMA, shape memory effect (SME) and super elasticity (SE). The significant coupling behaviour of SMA can be utilized as actuator in aerospace, automotive, electrical and civil fields. However, in practical applications, the coupling behaviour of SMA are non-linear and hysteretic. The control mechanism of SMA coupling behaviour is complex. Therefore, in order to achieve good control of thermomechanical properties, a highly controllable and promising heating technique is required. Thus, this paper reviewed the existing heating techniques for the SMA intending to find a controllable heating technique for the SMA. Besides that, this review suggested the promising induction heating for SMA thermomechanical characterization which offer temperature controllability and faster heating capability. However, till date most of research works are purely empirical. The present paper is able to provide an insight on the experimental approaches toward induction heating of SMA. Thus, the main aim of this paper is to provide a better understanding on the heating mechanism of SMA to develop an optimized utilization of SMA as an actuator.

Downloads