Characterization of Physical, Morphological and Mechanical Properties of Poly-Lactic Acid/Graphene (PLA/GNPs) Biopolymer Composites using Fused Deposition Modelling

DOI:

https://doi.org/10.37934/armne.27.1.112132Keywords:

Fused deposition modelling, mechanical properties, physical properties, microstructure, PLA, grapheneAbstract

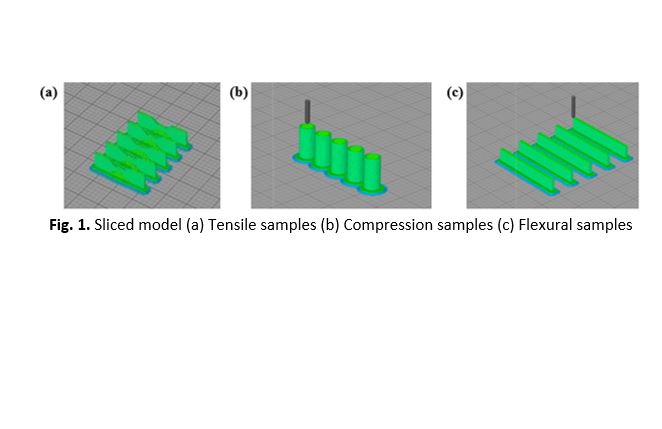

A hybrid biopolymer composite consisting of Poly-Lactic Acid/Graphene Nanoplatelets (PLA/GNPs) was formulated using double planetary mixer (DPM) and processed into granules and utilized as the feedstock for additive manufacturing (AM) of structures using the Fused Deposition Modelling (FDM) technique. The study aimed to investigate the influence of different weight percentages (1%, 3% and 5%) of graphene nanoplatelets (GNPs) on the physical, morphological and mechanical properties of the printed test samples. Differential Scanning Calorimetry (DSC) revealed the temperature ranges for the glass transition temperature (Tg) and crystallinity temperature (Tc) to be 61–63 °C and 112–140 °C, respectively. Additionally, it was observed that the presence of graphene in the polymer matrix led to a decrease in the melting temperature (Tm), with the sample containing 1 wt% of GNPs displaying the highest melting point. Furthermore, the density of the biopolymer composite increased as the weight percentage of GNPs increased. Microscopic examination of the samples revealed the presence of voids, waves and interlayer gaps in all compositions containing GNPs. These conditions were likely caused by inadequate material preparation and inaccurate printing parameter settings. In terms of mechanical properties, the highest tensile modulus observed was 1.29 GPa with 5 wt% GNPs, the highest flexural modulus was 5.17 GPa with 5 wt% GNPs and the highest compressive modulus was 10.073 GPa with 3 wt% GNPs. These results may be attributed to low homogeneity during the mixing process.

Downloads