Oil Palm Wastes Co-firing in an Opposed Firing 500 MW Utility Boiler: A Numerical Analysis

DOI:

https://doi.org/10.37934/cfdl.15.3.139152Keywords:

Computational Fluid Dynamics, Power Generation, Palm Oil Waste, Combustion, EmissionAbstract

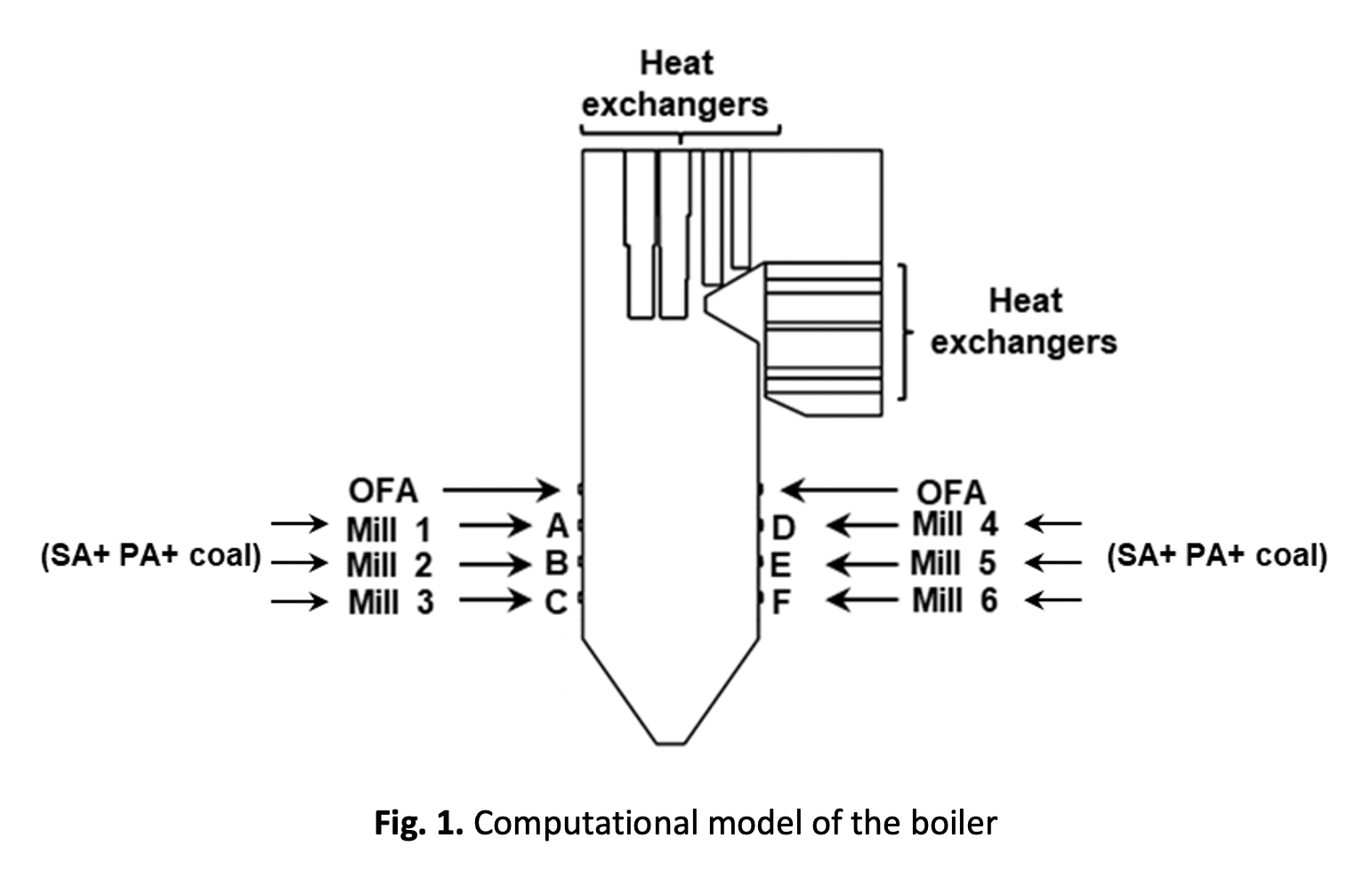

Malaysia is rich in palm oil plantations, where oil palm wastes (OPWs) are one of the readily accessible biomass resources. OPWs has the potential to be used as a fuel for electricity generation. Hence, the evaluation of OPWs co-firing for one of Malaysia's 500 MW utility boilers was executed numerically. Three types of OPWs were tested including empty fruit bunches (EFB), palm kernel shell (PKS), and palm mesocarp fibres (PMF). The predicted furnace exit gas temperature (FEGT) from the numerical model was validated against the actual FEGT from the power plant where the current boiler is situated, revealing a difference of less than 10%. The nose area temperature was predicted to exceed the cap of 1200°C in OPWs co-firing cases due to higher volatile matter (VM) in OPWs than the baseline of pure coal case, leading to higher levels of volatile release. When co-firing with OPWs, the predicted unburned carbon (UBC) at the boiler's outlet is lower because OPWs-coal blends contain less fixed carbon (FC) than the pure coal blend. UBC levels were anticipated to be lower than the loss of ignition (LOI) limit in all cases, highlighting its positive impact on carbon reduction. Slightly lowered mill performance was observed as a result of the calculated OPWs fuel flow surpassing the normal operation in the power plant to make up for the low gross calorific value (GCV) of OPWs while meeting the required load from the boiler. OPWs co-firing was predicted to emit lower carbon monoxide (CO) and carbon dioxide (CO2) than baseline coal due to lower FC. Nonetheless, higher thermal nitrogen oxides (NOx) were predicted due to the higher flame temperature created by OPWs co-firing. Even so, it is recommended that the ash mineral composition be included in future numerical studies since the ash minerals may have an effect on the emitted NOx.

Downloads

References

Cesaro, Zac, Matthew Ives, Richard Nayak-Luke, Mike Mason, and René Bañares-Alcántara. "Ammonia to power: Forecasting the levelized cost of electricity from green ammonia in large-scale power plants." Applied Energy 282 (2021): 116009. https://doi.org/10.1016/j.apenergy.2020.116009

Cardoso, João Sousa, Valter Silva, José Antonio Mayoral Chavando, Daniela Eusébio, and Matthew J. Hall. "Numerical modelling of the coal phase-out through ammonia and biomass co-firing in a pilot-scale fluidized bed reactor." Fuel Communications 10 (2022): 100055. https://doi.org/10.1016/j.jfueco.2022.100055

Zhang, Juwei, Takamasa Ito, Hiroki Ishii, Sakiko Ishihara, and Toshiro Fujimori. "Numerical investigation on ammonia co-firing in a pulverized coal combustion facility: Effect of ammonia co-firing ratio." Fuel 267 (2020): 117166. https://doi.org/10.1016/j.fuel.2020.117166

Tsukada, Naruhito, Naoki Kinoshita, Yutaka Kabuki, Yuzo Taguchi, Yohei Takashima, Toshikazu Tsumura, and Masayuki Taniguchi. "Role of OH radical in fuel-NOx formation during cocombustion of ammonia with hydrogen, methane, coal, and biomass." Energy & Fuels 34, no. 4 (2020): 4777-4787. https://dx.doi.org/10.1021/acs.energyfuels.0c00356

Weng, Wubin, Zhongshan Li, Paul Marshall, and Peter Glarborg. "Participation of alkali and sulfur in ammonia combustion chemistry: Investigation for ammonia/solid fuel co-firing applications." Combustion and Flame 244 (2022): 112236. https://doi.org/10.1016/j.combustflame.2022.112236

Aziz, Muhammad, Dwika Budianto, and Takuya Oda. "Computational fluid dynamic analysis of co-firing of palm kernel shell and coal." Energies 9, no. 3 (2016): 137. https://doi.org/10.3390/en9030137

Ishihara, Sakiko, Juwei Zhang, and Takamasa Ito. "Numerical calculation with detailed chemistry on ammonia co-firing in a coal-fired boiler: Effect of ammonia co-firing ratio on NO emissions." Fuel 274 (2020): 117742. https://doi.org/10.1016/j.fuel.2020.117742

Zhu, Jingji, Xiaowei Liu, Yishu Xu, Jingying Xu, Huakun Wang, Kai Zhang, Xiaobei Cheng, and Dunxi Yu. "Probing into Volatile Combustion Flame and Particulate Formation Behavior During the Coal and Ammonia Co-firing Process." Energy & Fuels 36, no. 16 (2022): 9347-9356. https://doi.org/10.1021/acs.energyfuels.2c01450

Wang, Xin, Weidong Fan, Jun Chen, Guanyu Feng, and Xiang Zhang. "Experimental study and kinetic analysis of the impact of ammonia co-firing ratio on products formation characteristics in ammonia/coal co-firing process." Fuel 329 (2022): 125496. https://doi.org/10.1016/j.fuel.2022.125496

Xu, Yishu, Huakun Wang, Xiaowei Liu, Jingji Zhu, Jingying Xu, and Minghou Xu. "Mitigating CO2 emission in pulverized coal-fired power plant via co-firing ammonia: A simulation study of flue gas streams and exergy efficiency." Energy Conversion and Management 256 (2022): 115328. https://doi.org/10.1016/j.enconman.2022.115328

Chen, Ping, Yao Fang, Peipei Wang, Mingyan Gu, Kun Luo, and Jianren Fan. "The effect of ammonia co-firing on NO heterogeneous reduction in the high-temperature reduction zone of coal air-staging combustion: Experimental and quantum chemistry study." Combustion and Flame 237 (2022): 111857. https://doi.org/10.1016/j.combustflame.2021.111857

Ishihara, Sakiko, Juwei Zhang, and Takamasa Ito. "Numerical calculation with detailed chemistry of effect of ammonia co-firing on NO emissions in a coal-fired boiler." Fuel 266 (2020): 116924. https://doi.org/10.1016/j.fuel.2019.116924

Rahman, Mohammad Nurizat, and Mazlan Abdul Wahid. "Renewable-based zero-carbon fuels for the use of power generation: A case study in Malaysia supported by updated developments worldwide." Energy Reports 7 (2021): 1986-2020. https://doi.org/10.1016/j.egyr.2021.04.005

Rahman, Mohammad Nurizat, Mohd Haffis Ujir, Mazlan Abdul Wahid, and Mohd Fairus Mohd Yasin. "A single-step chemistry mechanism for biogas supersonic combustion velocity with nitrogen dilution." Journal of Thermal Analysis and Calorimetry (2022): 1-15. https://doi.org/10.1007/s10973-022-11356-x

Rahman, Mohammad Nurizat, Norshakina Shahril, and Suzana Yusup. "Hydrogen-Enriched Natural Gas Swirling Flame Characteristics: A Numerical Analysis." CFD Letters 14, no. 7 (2022): 100-112. https://doi.org/10.37934/cfdl.14.7.100112

Chen, Ping, Huichun Wang, Boyu Jiang, Ying Wang, Mingyan Gu, Guang Chen, and Xiangyong Huang. "An experimental and theoretical study of NO heterogeneous reduction in the reduction zone of ammonia co-firing in a coal-fired boiler: Influence of CO." Fuel Processing Technology 231 (2022): 107184. https://doi.org/10.1016/j.fuproc.2022.107184

Yacob, Noraishah Shafiqah, and Hassan Mohamed. "Investigation of Palm Oil Wastes Characteristics for Co-Firing with Coal." Journal of Advanced Research in Applied Sciences and Engineering Technology 23, no. 1 (2021): 34-42. https://doi.org/10.37934/araset.23.1.3442

Wu, Qibai, Thien Ching Qiang, Guoxun Zeng, Haiyan Zhang, Ye Huang, and Yaodong Wang. "Sustainable and renewable energy from biomass wastes in palm oil industry: A case study in Malaysia." International Journal of Hydrogen Energy 42, no. 37 (2017): 23871-23877. https://doi.org/10.1016/j.ijhydene.2017.03.147

Subramaniam, Vijaya, Soh Kheang Loh, and Astimar Abdul Aziz. "GHG analysis of the production of crude palm oil considering the conversion of agricultural wastes to by-products." Sustainable Production and Consumption 28 (2021): 1552-1564. https://doi.org/10.1016/j.spc.2021.09.004

Purnomo, Fajar, and Atok Setiyawan. "Numerical study on in-furnace blending coal combustion characteristics in a 625 MW tangentially fired pulverized coal boiler." In AIP Conference Proceedings, vol. 2187, no. 1, p. 020038. AIP Publishing LLC, 2019. https://doi.org/10.1063/1.5138293

Baek, Se Hyun, Ho Young Park, and Sung Ho Ko. "The effect of the coal blending method in a coal fired boiler on carbon in ash and NOx emission." Fuel 128 (2014): 62-70. http://dx.doi.org/10.1016/j.fuel.2014.02.043

Wang, Chang’an, Qinqin Feng, Qiang Lv, Lin Zhao, Yongbo Du, Pengqian Wang, Jingwen Zhang, and Defu Che. "Numerical investigation on co-firing characteristics of semi-coke and lean coal in a 600 MW supercritical wall-fired boiler." Applied Sciences 9, no. 5 (2019): 889. https://doi.org/10.3390/app9050889

Lee, Byoung-Hwa, Eric G. Eddings, and Chung-Hwan Jeon. "Effect of coal blending methods with different excess oxygen on unburned carbon and NOx emissions in an entrained flow reactor." Energy & fuels 26, no. 11 (2012): 6803-6814. https://doi.org/10.1021/ef300562t

Lee, Byoung-hwa, Seoung-gon Kim, Ju-hun Song, Young-june Chang, and Chung-hwan Jeon. "Influence of coal blending methods on unburned carbon and NO emissions in a drop-tube furnace." Energy & fuels 25, no. 11 (2011): 5055-5062. https://doi.org/10.1021/ef200783q

Hariana, Feri Karuana, Prabowo, Edi Hilmawan, Arif Darmawan, and Muhammad Aziz. "Effects of Different Coals for Co-Combustion with Palm Oil Waste on Slagging and Fouling Aspects." Combustion Science and Technology (2022): 1-23. https://doi.org/10.1080/00102202.2022.2152684

Rahman, Mohammad Nurizat, Mohd Fairus Mohd Yasin, and Mohd Shiraz Aris. "Reacting Flow Characteristics and Multifuel Capabilities of a Multi-Nozzle Dry Low NOx Combustor: A Numerical Analysis." CFD Letters 13, no. 11 (2021): 21-34. https://doi.org/10.37934/cfdl.13.11.2134

Rahman, Mohammad Nurizat, Mohd Shiraz Aris, Mohd Haffis Ujir, and Mohd Hariffin Boosroh. "Predictive Numerical Analysis to Optimize Ventilation Performance in a Hydropower Surge Chamber for H2S Removal." CFD Letters 13, no. 10 (2021): 69-80. https://doi.org/10.37934/cfdl.13.10.6980

Rahman, M. N., M. A. Wahid, and MF Mohd Yasin. "Predictive Numerical Analysis on the Fuel Homogeneity in a Rotating Detonation Engine (RDE) Implementing Radially-Entered Fuel Injection Scheme." In IOP Conference Series: Materials Science and Engineering, vol. 884, no. 1, p. 012109. IOP Publishing, 2020. https://iopscience.iop.org/article/10.1088/1757-899X/884/1/012109

Mazlan, Muhammad Amri, Mohd Fairus Mohd Yasin, Saat Aminuddin, Mazlan Abdul Wahid, Ahmad Dairobi Ghazali, and Mohammad Nurizat Rahman. "Initiation Characteristics of Rotating Supersonic Combustion Engine." Evergreen 8, no. 1 (2021): 177-181. https://doi.org/10.5109/4372275

Rahman, Mohammad Nurizat, Mazlan Abdul Wahid, Mohd Fairus Mohd Yasin, Abidin Ummikalsom, and Muhammad Amri Mazlan. "Predictive Numerical Analysis on the Mixing Characteristics in a Rotating Detonation Engine (RDE)." Evergreen 8, no. 1 (2021): 123-130. https://doi.org/10.5109/4372268

Rahman, Mohammad Nurizat, Norshakina Shahril, Suzana Yusup, and Ismail Shariff. "Hydrogen Co-Firing Characteristics in a Single Swirl Burner: A Numerical Analysis." In IOP Conference Series: Materials Science and Engineering, vol. 1257, no. 1, p. 012020. IOP Publishing, 2022. https://doi.org/10.1088/1757-899X/1257/1/012020

Shi, Hang, Yuxin Wu, Man Zhang, Yang Zhang, and Junfu Lyu. "Ash deposition of Zhundong coal in a 350 MW pulverized coal furnace: Influence of sulfation." Fuel 260 (2020): 116317. https://doi.org/10.1016/j.fuel.2019.116317

Wang, Yongzhen, Jing Jin, Dunyu Liu, Haoran Yang, and Xuesen Kou. "Understanding ash deposition for Zhundong coal combustion in 330 MW utility boiler: Focusing on surface temperature effects." Fuel 216 (2018): 697-706. https://doi.org/10.1016/j.fuel.2017.08.112

Cai, Yongtie, Kunlin Tay, Zhimin Zheng, Wenming Yang, Hui Wang, Guang Zeng, Zhiwang Li, Siah Keng Boon, and Prabakaran Subbaiah. "Modeling of ash formation and deposition processes in coal and biomass fired boilers: A comprehensive review." Applied Energy 230 (2018): 1447-1544. https://doi.org/10.1016/j.apenergy.2018.08.084

Rahman, Mohammad Nurizat, and Nor Fadzilah Binti Othman. "A numerical model for ash deposition based on actual operating conditions of a 700 MW coal-fired power plant: Validation feedback loop via structural similarity indexes (SSIMs)." CFD Letters 14, no. 1 (2022): 99-111. https://doi.org/10.37934/cfdl.14.1.99111

Rahman, Mohammad Nurizat. "Optimisation of Solid Fuel In-furnace Blending for an Opposed-firing Utility Boiler: A Numerical Analysis." CFD Letters 14, no. 9 (2022): 89-107. https://doi.org/10.37934/cfdl.14.9.89107

Yang, Joo-Hyang, et al. "Effects of detailed operating parameters on combustion in two 500-MWe coal-fired boilers of an identical design." Fuel 144 (2015): 145-156. https://doi.org/10.1016/j.fuel.2014.12.017

Ferziger, Joel H., Milovan Perić, and Robert L. Street. Computational methods for fluid dynamics. Vol. 3. Berlin: springer, 2002. https://doi.org/10.1007/978-3-319-99693-6

Sun, Jian, et al. "Numerical investigation of a non-premixed hollow rotating detonation engine." international journal of hydrogen energy 44.31 (2019): 17084-17094. https://doi.org/10.1016/j.ijhydene.2019.04.168

Sakuragi, Kiyoshi, and Maromu Otaka. "Effect of biomass carbonization on the grinding of coal/biomass mixtures." ACS omega 5, no. 34 (2020): 21722-21727. https://pubs.acs.org/doi/10.1021/acsomega.0c02629#

Du, Lianxiang, Kevin J. Folliard, and David Trejo. "Effects of constituent materials and quantities on water demand and compressive strength of controlled low-strength material." Journal of materials in Civil Engineering 14, no. 6 (2002): 485-495. https://doi.org/10.1061/(ASCE)0899-1561(2002)14:6(485)