Effect of Machining Parameters on Micro-Burrs Formation of Aluminium Puncher using High-Speed Machining Process

DOI:

https://doi.org/10.37934/aram.115.1.4760Keywords:

Micro-burr formation, micro-milling, high-speed machiningAbstract

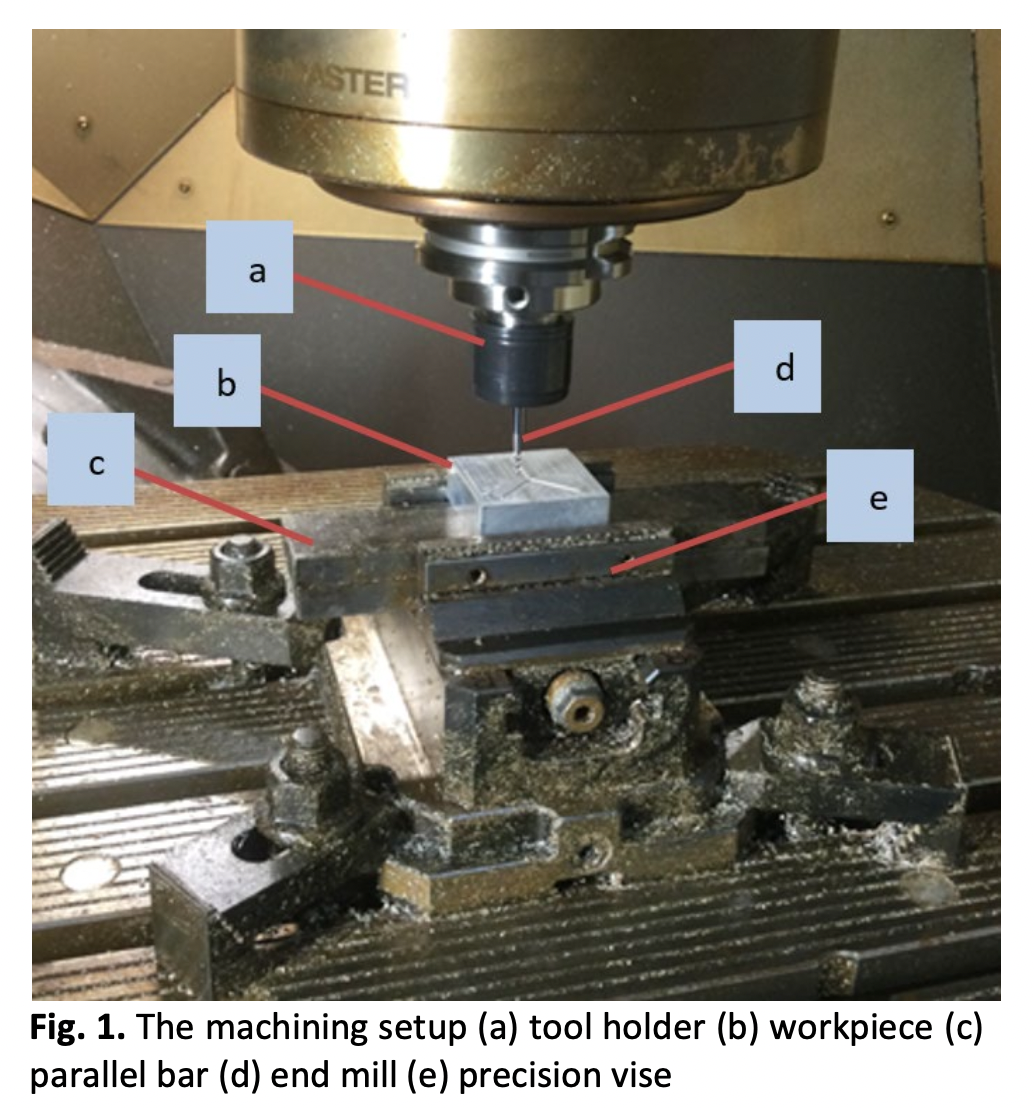

Micro-burrs are small protrusions or imperfections that can form on the surface of a machined part during the machining process, which may lead to reduced product quality, decreased performance, and increased wear and tear. The formation of micro-burrs on the puncher can adversely affect the accuracy and surface finish of replicated microchannel parts in secondary processes like hot embossing. The objective of this study is to investigate the effect of machining parameters on micro-burr formation in the Y-type Al6061-T6 microchannel puncher. The machining parameters include spindle speed, feed rate, and depth of cut in twenty experimental works designed using the Central Composite Design (CCD) approach for machining with uncoated solid carbide end milling tools. Results indicate that the top micro-burr formation in the Y-type Al6061-T6 microchannel puncher is significantly influenced by feed rates compared to spindle speed and depth of cut. The minimum burr width occurs at a feed rate of 30 mm/min, while maximum burr values are observed at 150 mm/min. The best parameter combination identified in this study is a spindle speed of 14000 r/min, a feed rate of 90 mm/min, and a moderate depth of cut of 50 μm. This knowledge can be applied to selecting appropriate cutting parameters when planning microchannel puncher fabrication using a high-speed machining process to achieve precision and minimize burr formation.

Downloads