Investigating Roughness Effect to Geometrically Necessary Dislocation in Micro-Indentation using Finite Element Analysis

DOI:

https://doi.org/10.37934/aram.104.1.2532Keywords:

Geometrically necessary dislocation, surface roughness, hardness, size effect, Finite Element AnalysisAbstract

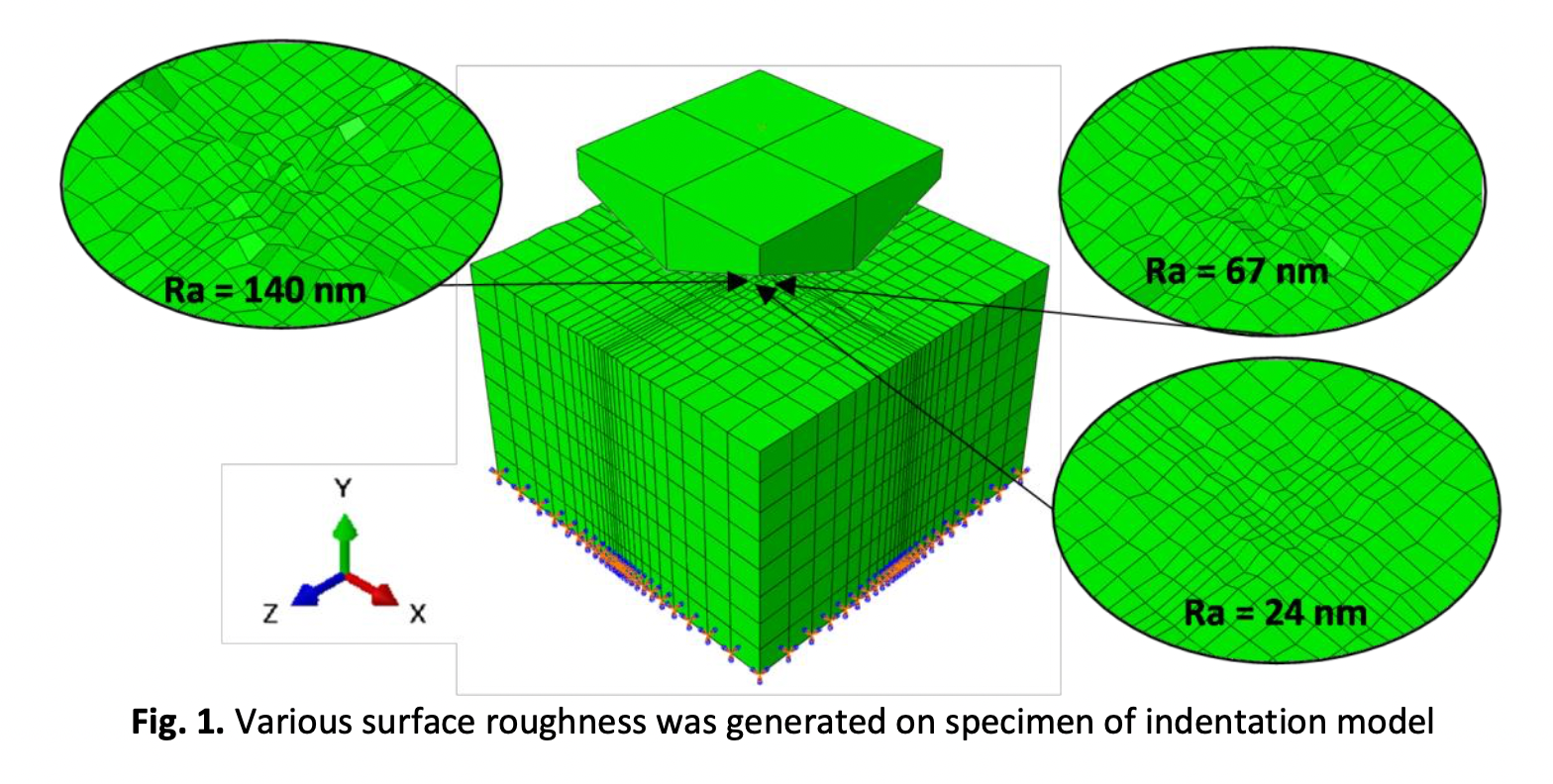

Surface roughness is a well-known factor in effecting to the hardness value in low indentation depth. The rougher surface induces a greater hardness value. However, the hardening mechanisms, such as the effect of geometrically necessary dislocations (GNDs), with surface roughness is rarely discussed. Therefore, the current study revealed the relationship between the surface roughness effect and the material dislocation through GNDs by using finite element analysis. 3D Crystal plasticity finite element indentation model was developed with various surface roughness between 24 to 140 nm and a range of indentation depth 3.55 to 12.27 µm to indent on the copper (111) material. The experimental indentation work was performed to validate the finite element model. The surface roughness was discovered to contribute to GND density. The GNDs distribution is highly dependent on the geometry of surface asperities, as the surface get rougher the GNDs distribution tends to be inhomogeneous. The GND density is exponentially proportional to the roughness effect. The GND density increases from 3.58 × 1014 m-2 for surface roughness 24 nm to 1.01 × 1015 m-2 for surface roughness 140 nm at indentation depth 3.55 µm. Therefore, GND density which contributes to hardening effect causes rougher surface to induce greater hardness value.

Downloads