The Investigation of Material Removal Rate on Electrical Discharge Machining of Titanium Alloys (Ti-6Al-4V) at Different Peak Currents and Pulse Durations by Using RBD Palm Oil and Kerosene as Dielectric Fluids

DOI:

https://doi.org/10.37934/aram.115.1.141151Keywords:

Material removal rate, surface topography, electrical discharge machining, titanium alloy, RBD palm oilAbstract

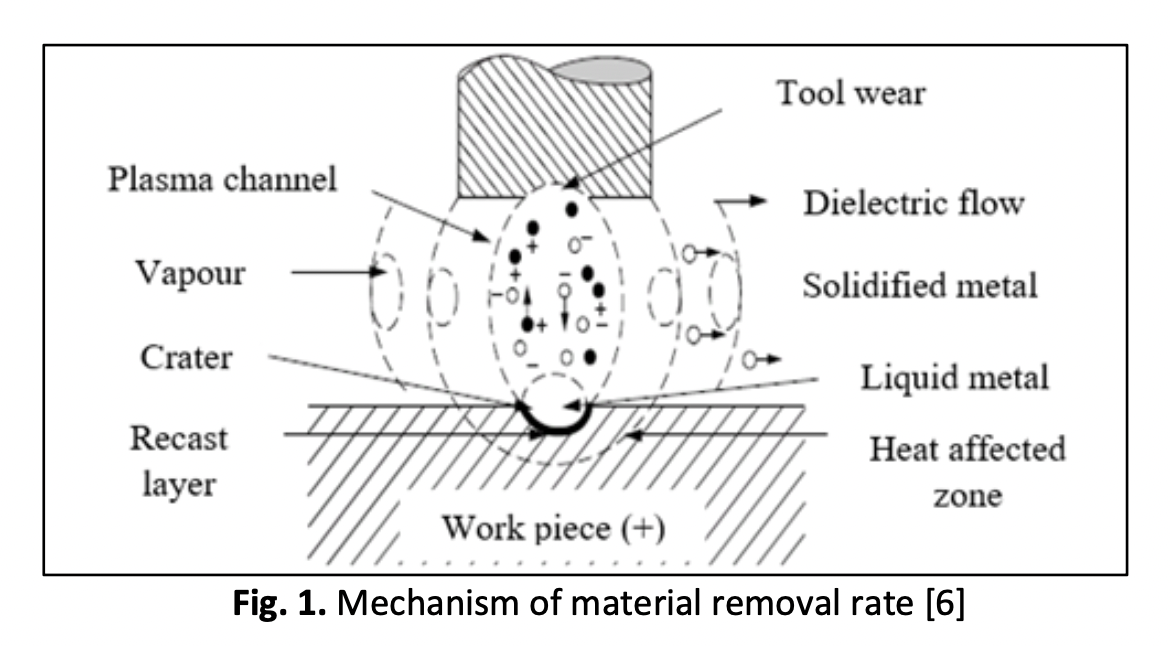

The type of dielectric fluid is the most significant component that might affect the machining performance of EDM such as material removal, tool wear, and electrode surface roughness. However, the most serious of these issues is the inability to comply with health and environmental rules when the conventional dielectric was harmful to the surrounding ecosystem. One approach to ensure the long-term sustainability of EDM is to use vegetable oil as the dielectric fluid as it is environmentally friendly and biodegradable. To satisfy industrial objectives, the machining industry must ensure that the maximum material removal rate (MRR) can be achieved. This paper investigated the effect of kerosene and refined, bleached, and deodorised (RBD) palm oil as dielectric fluids with different peak currents (6, 9, and 12A) and pulse duration (50, 100 and 150µs) settings on MRR of Titanium alloy. Kerosene was used as a benchmark to compare the performance of the EDM process. The implementation of RBD palm oil recorded the lowest MRR at the lowest peak current of 6A with the lowest pulse duration of 50µs, which is 1.1260mm3/min. In contrast, the highest MRR with a value of 12.1323mm3/min was recorded at the highest peak current of 12A with a pulse duration of 150µs. Overall, RBD palm oil shows an excellent MRR performance for substituting hydrocarbon or mineral oil as a dielectric fluid in EDM applications, improving cost, time, and production efficiency.

Downloads