Design of Industrial Mg-Rich Gypsum Waste with Concrete Waste Aggregate for Compressibility of Problematic Soil

DOI:

https://doi.org/10.37934/aram.116.1.103116Keywords:

Concrete waste aggregate, industrial waste, soil stabilization, peat compressibilityAbstract

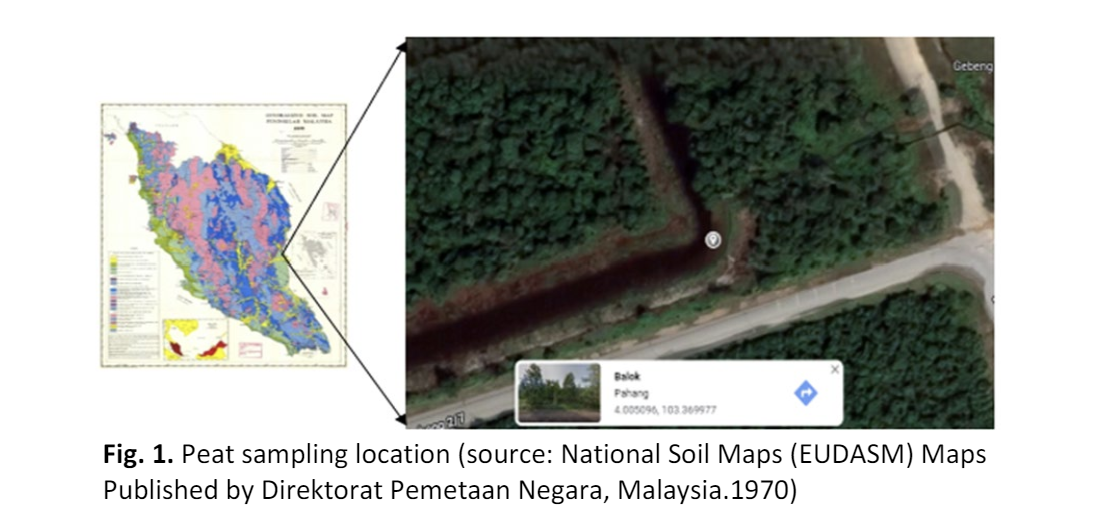

Peats are often considered as a geotechnically problematic soil due to their poor behaviour and exhibit low soil properties like high compressibility, low shear strength, high fibre content, high moisture content and low bearing capacity values. Chemical stabilization was proven to be an effective method to stabilize the problematic soil. To date many additives like Ordinary Portland Cement, fly ash, lime and other alternatives binder has been applied to improve the compressive strength of the problematic soil. The study describes the effect of compressibility of improved peat soil using waste from industrial such as Mg-rich synthetic gypsum (MRSG) by-product and concrete waste aggregate from institution laboratory waste that can be used to improve the settlement problem of the Gebeng, Malaysia peat soil. The test was conducted at varying percentages of MRSG and concrete waste aggregate additives at 5%, 10%, 15%, and 20% by weight of the soil. The unconfined compression strength (UCS) test was determined to obtain the optimum strength ratio and the data revealed that the optimum ratio of gypsum and concrete waste required to enhance the properties of peat soil were at 5% gypsum, 10% concrete waste, and 10% concrete waste combined with 10% gypsum. Coefficient of consolidation, compression index, and coefficient of volume compressibility were obtained by oedometer test for both untreated and treated peat soil with additives. The compression ratio of the peat soil indicated the peat was very compressible and however, the compression ratio was observed at very slightly compressible once the soil stabilized with the optimum ratio mix. The results indicated that the combination of these two additives improved the compressibility characteristics of peat soil. This research will contribute to the fundamental behaviour of geotechnical problematic soil in Malaysia which results in sustainable approach by recycling the industrial and institutional waste, Mg-rich gypsum and concrete waste aggregate for soil improving instead of implementing soil removal replacing techniques.

Downloads