Preparation and Characterization of Nano Lanthanum Dioxide Fortified with Magnesium Alloy

DOI:

https://doi.org/10.37934/aram.114.1.173181Keywords:

Metal Matrix Composites (MMCs), X-Ray Diffraction (XRD), Fourier Transform Infrared (FTIR), Raman SpectroscopesAbstract

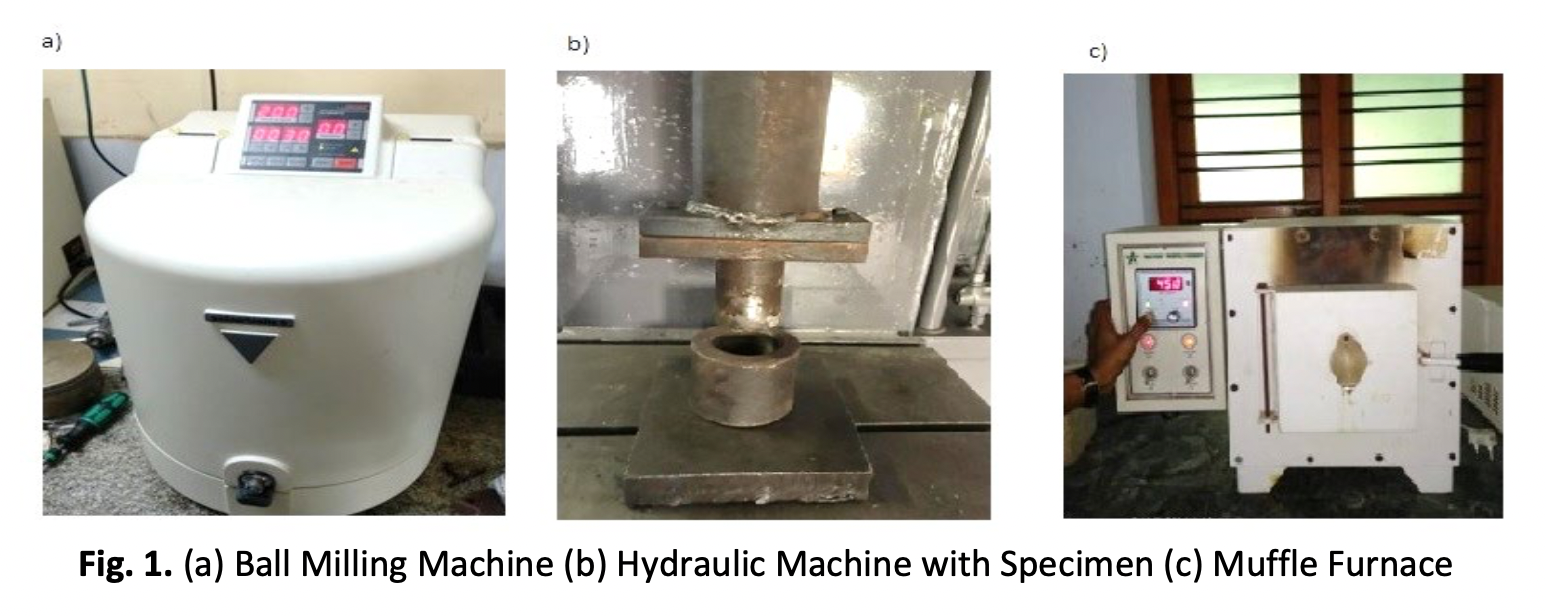

Nano silicon dioxide alloy-based Metal Matrix Composites (MMCs) and other high temperature ceramics-based Magnesium (Mg) metals are the subject of a lot of study nowadays. An in-depth examination of the data on structure, characteristics and known metal matrix connecting techniques has all the makings of being beneficial. The most notable attribute of Nano Silicon dioxide is its ability to generate a large number of auxiliary modifications without altering its component. The use of nano-sized atoms is a delayed result of better MMCs and matrix mix malleability. The current investigation includes the construction and testing of cutting-edge Nano-SiO2 cross variety particles with Mg Metal Matrix and lanthanum dioxide particles created by a ball preparation method. Powder mixtures including a constant weight fraction of SiO2 and Mg metal matrix as uniaxial cold crushed assist components are often used. The green compacts are then ball handled in an electric smother warmer. Mechanical characteristics of the microstructure and composites, such as scaled down scale hardness, thickness and inflexibility, were considered. The microstructure was studied using X-Ray Diffraction (XRD) and Fourier Transform Infrared (FTIR). According to the findings, nano Silicon metal matrix particles improve mechanical qualities.