Heat Pipe as a Passive Cooling Device for PV Panel Performance Enhancement

DOI:

https://doi.org/10.37934/araset.28.2.190198Keywords:

Passive cooling, PV panel, heat pipeAbstract

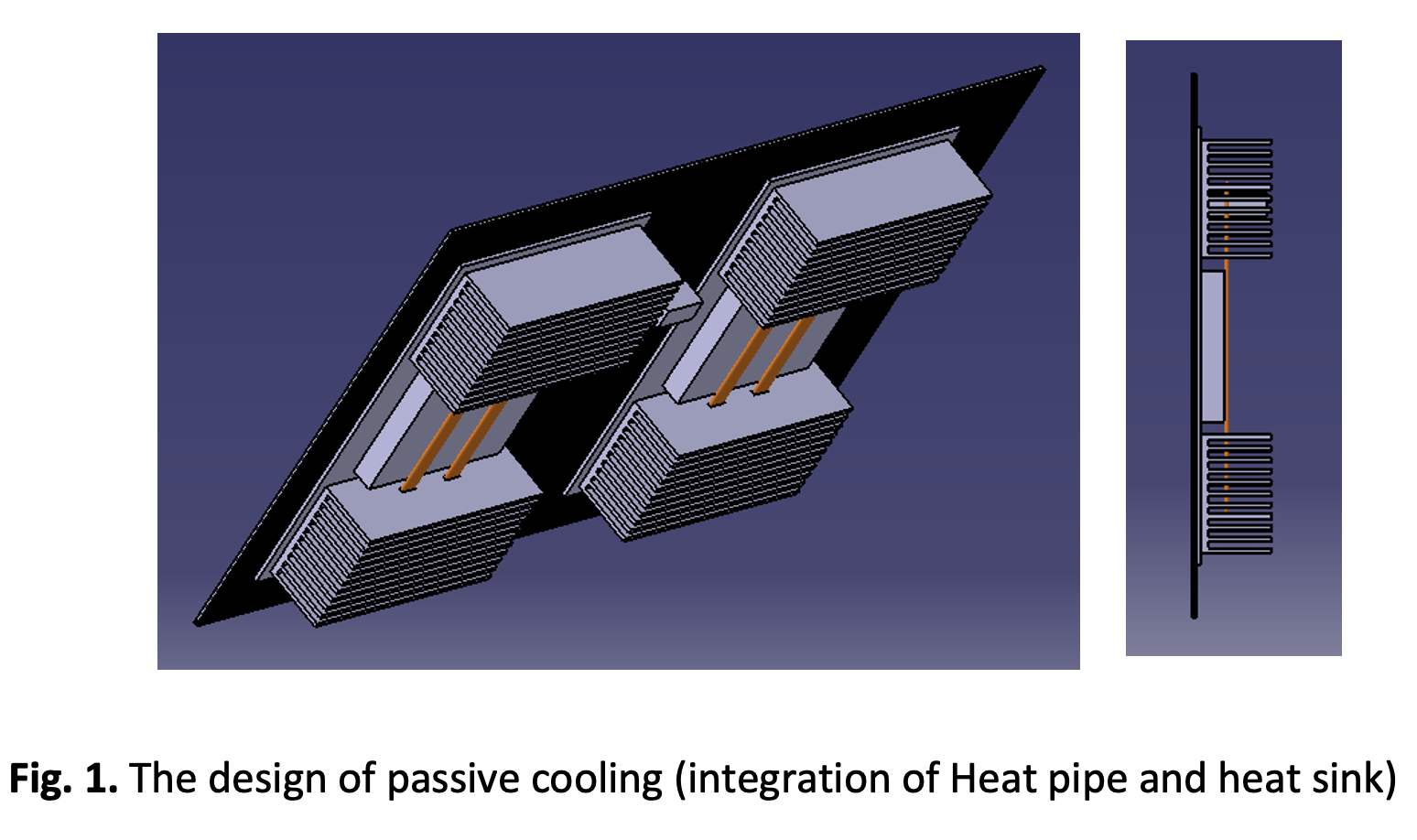

Excessive operating temperature of Photovoltaic (PV) panel by high levels of solar irradiation would affect its conversion efficiency, Hence One way of improving the efficiency of photovoltaic system is to maintain a low operating temperature by introducing a passive cooling system. Subsequently, this study investigating the effect on surface temperature reduction and voltage output of PV panel, by introducing the combination of heat pipe and fin as a cooling device. Each set of the cooling devices consisted of two copper heat pipes and two units of heat sinks. Two sets of the cooling devices were installed at the back of the PV panel, and experimental work had been performed at fixed 0 ° horizontally. The experiment was conducted at a constant time under Malaysia’s climate at constant ambient temperature ranging from 33 °C to 34 °C. The temperature of the panel and open-circuit voltage (VOC) was recorded before and after the installation of the cooling system by using Arduino data logger. Four thermocouples for different places and a voltage sensor were installed into the system to enable recording the data of voltage and temperature simultaneously. The results showed 4 o C or 6.6 % surface temperature reduction and 0.29 V or 2.8 % voltage gained respectively when the proposed cooling devices were installed to the PV panel.Downloads

Downloads

Published

2022-10-22

How to Cite

Mahamad Hisyam Mahamad Basri, Yusli yaakob, Zulkhairi Kamaruzaman, Fairosidi Idrus, Norasikin Hussin, & Idris Saad. (2022). Heat Pipe as a Passive Cooling Device for PV Panel Performance Enhancement . Journal of Advanced Research in Applied Sciences and Engineering Technology, 28(2), 190–198. https://doi.org/10.37934/araset.28.2.190198

Issue

Section

Articles