Influence of Compound Spherical Trenched Holes on Film Cooling Performance at the end of Combustor Simulator

DOI:

https://doi.org/10.37934/araset.28.1.1324Keywords:

Gas Turbine Engine, Film-Cooling, Trench Hole, Dilution HoleAbstract

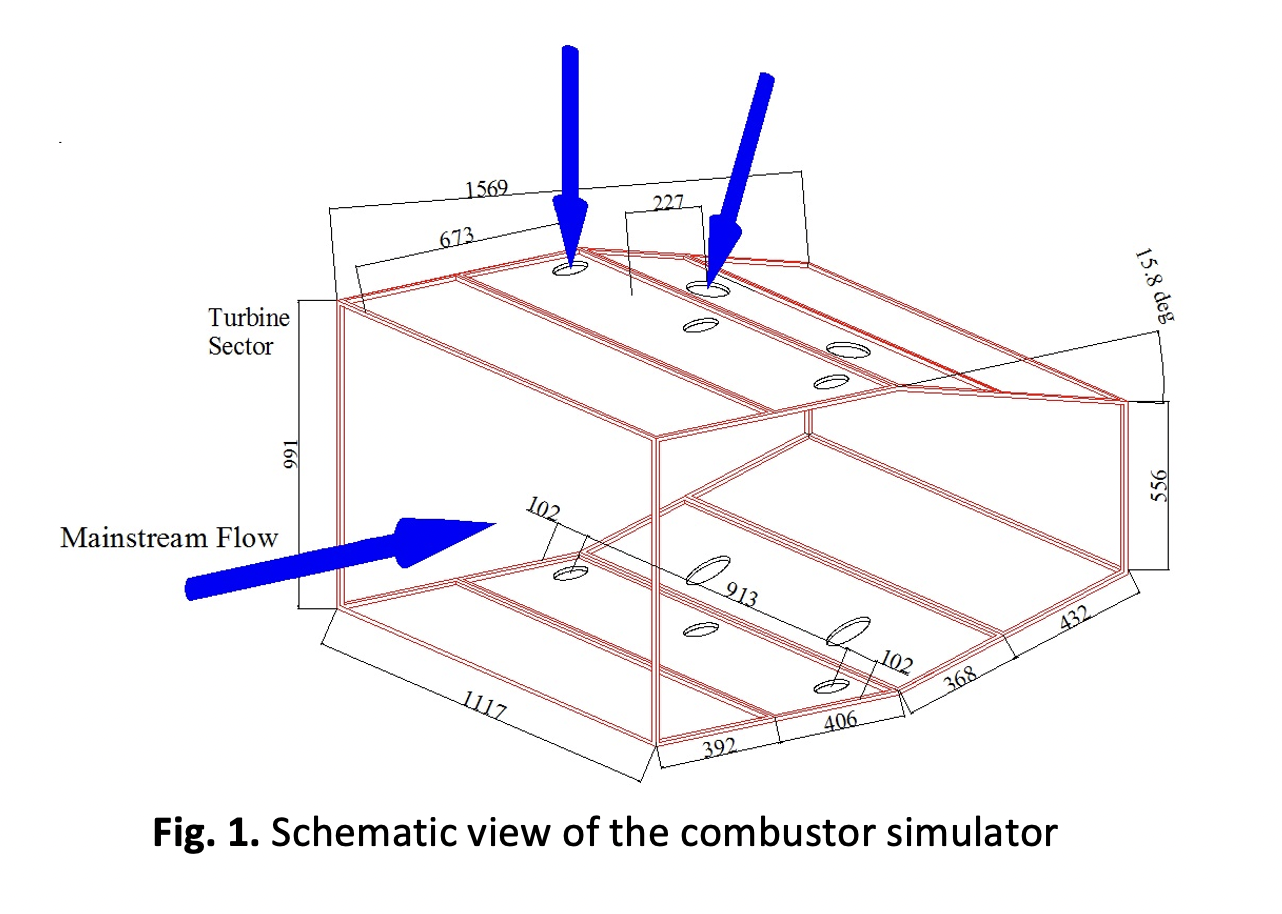

The major effects of cylindrical and spherical trenched cooling holes with distance between the hole surface and the combustion chamber panel and the filler diameter on the spherical hole contact surface and the panel surface H=0.3,R=D/2=0.1, H=0.3, R=D/2=0.2 and H=0.3, R=D/2=0.3 cm at BR=3.18 on the film cooling effectiveness near the combustor end wall surface is an important subject to study in details. In this research, a three-dimensional representation of a Pratt and Whitney gas turbine engine was simulated and analysed with a commercial finite volume package FLUENT 6.2.26. The analyses were done with RANS turbulence model on internal cooling passages. The combustor simulator was combined with the interaction of two rows of dilution jets, which were staggered in the streamwise direction and aligned in the spanwise direction. In comparison with the baseline case, the application of trenched holes increased the effectiveness of film cooling up to 47% near the wall surface and an average of 35% in depth of combustor simulator .Downloads

Downloads

Published

2022-09-11

How to Cite

Nor Azwadi Che Sidik, & Ehsan Kianpour. (2022). Influence of Compound Spherical Trenched Holes on Film Cooling Performance at the end of Combustor Simulator . Journal of Advanced Research in Applied Sciences and Engineering Technology, 28(1), 13–24. https://doi.org/10.37934/araset.28.1.1324

Issue

Section

Articles