Using Glucose as Protein Remover from Rubber Films with One Pot Method

DOI:

https://doi.org/10.37934/araset.51.1.195210Keywords:

Deproteinization, High ammonia natural rubber latex, Rubber films, Opacity, Film characteristicsAbstract

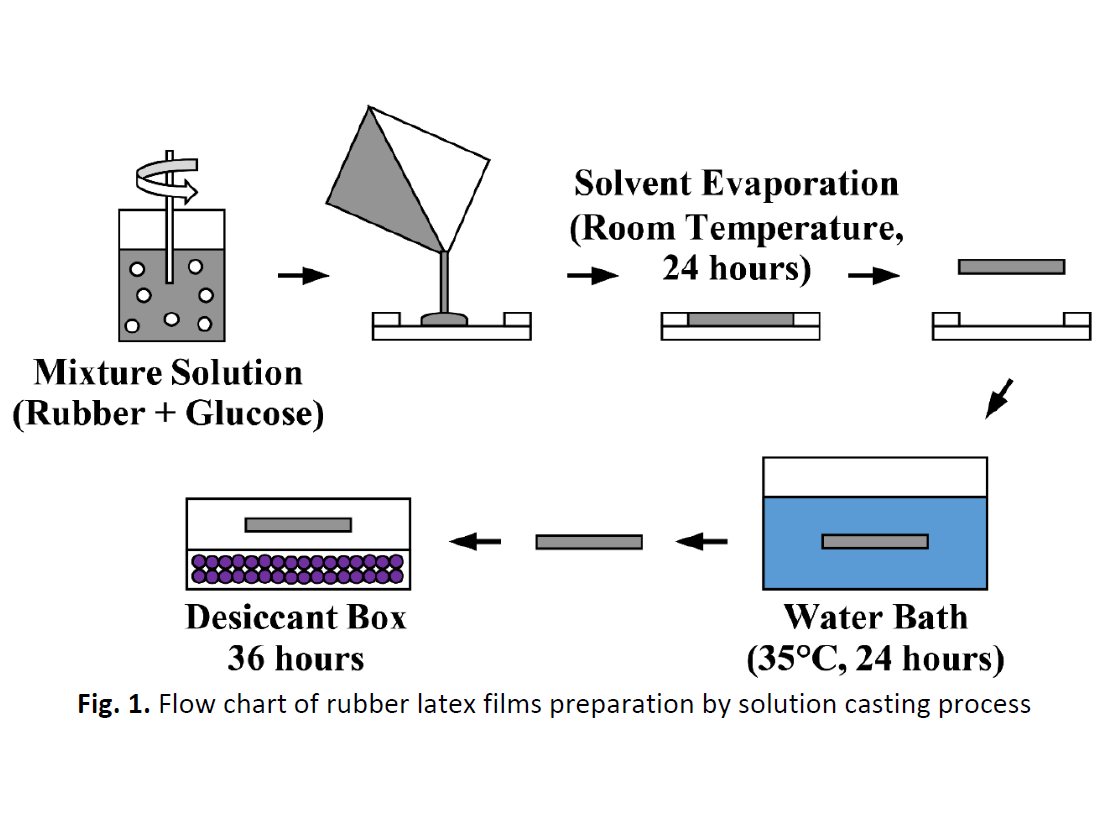

One of Thailand’s important agricultural products, particularly in the south, is high ammonia natural rubber latex (HANR) concentrate. Numerous products, including dip-moulded products, rubber films, and foams, are made with this latex. The protein content inside latex is one issue that may happen when using it. This is because those who have contact with rubber products can get allergic reactions as the result of these proteins. Before using latex, these proteins are typically removed in the form of latex. In order to digest these proteins, both chemicals and enzymes may be used. It is very rare to remove protein with a solid rubber product. In this study, raw rubber films were used to deproteinize employing a simple one-pot technique using glucose as protein remover. Glucose was used at a various concentration of 0, 5, 10, 15, and 20 phr by mixing with HANR. The films were subsequently produced by casting, dried, and then submerged in water for glucose leaching. A preliminary analysis of the chemical structure using the FTIR technique demonstrated in removing glucose from the rubber. According to a comparison of deproteinization determined by using total nitrogen analyser between the removal of protein in latex with EDTA solution combined with high-speed centrifugation technique as basic method and the use of glucose, the amount of protein removed in the first method was around 80%, whereas the use of glucose is over 50%. Water absorption, light transmission, as well as opacity and morphological characteristics, are further characteristics that use to compared between rubber film properties made by both deproteinization methods. It was found that the films produced using EDTA performed better than those produced with glucose to remove protein, but not considerably better. Meanwhile, both techniques of protein removal did not significantly affect the produced rubber films mechanical characteristics. The explanation for using glucose to remove protein from rubber as well as the findings will be discussed in more details in this research work.