Rich Dad and Poor Dad: Biomass Circularity Science Empathizing Rubber Smallholders

DOI:

https://doi.org/10.37934/araset.29.1.207222Keywords:

Biomass, circularity, bioeconomy, resource-efficient, rubber smallholdersAbstract

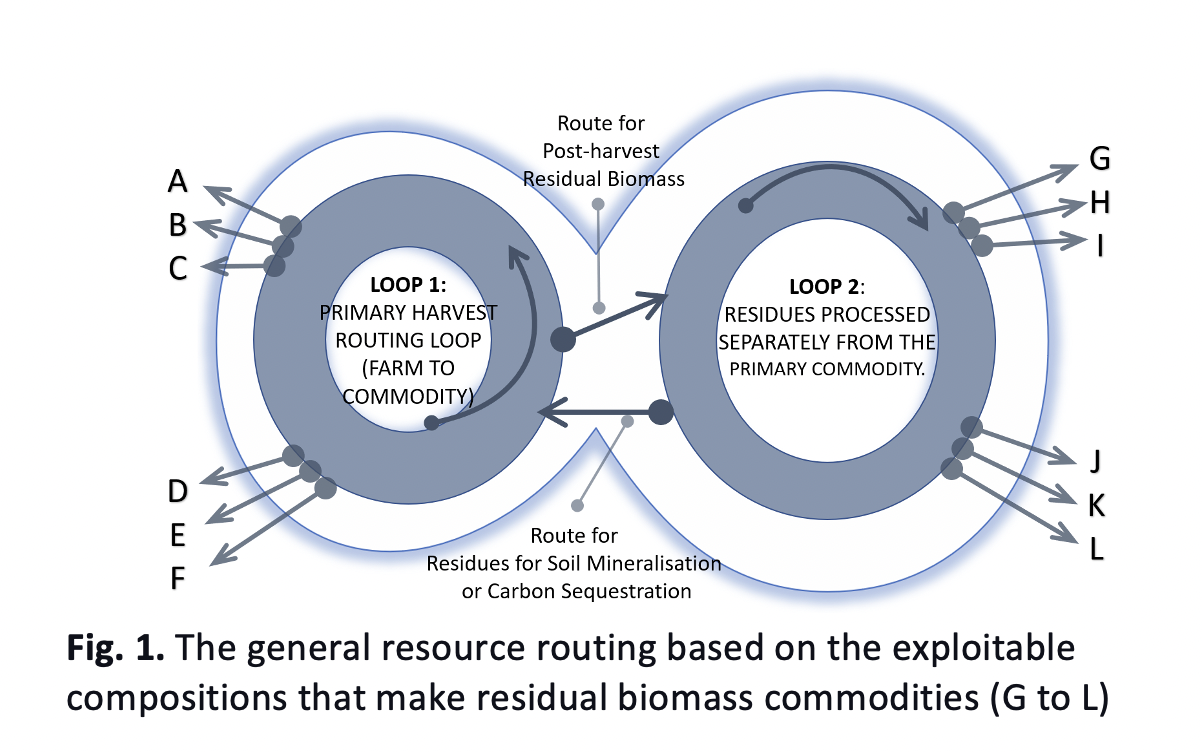

Analysis of rubber and rubberwood biomass management revealed an actualized twin-loop circularity arising from the multibillion-dollar export revenue downstream and upstream segments. Despite resembling zero-waste and resource-efficient system, the revenue from natural rubber exports does not translate as the wealth of rubber smallholders, pressing them as the persistent ‘poor dad’ in the rubber value chain. This study dwells on how to empower the smallholders through high-quality rubber production efficiency to compensate for the nose-diving rubber price. Analysis of the challenges facing the seemingly forced labor recognized operational costs as the main hindrance to productivity. Mapping the challenges to solutions identified the need for immediate actions and the transformative actionable educational approach for deploying an efficient upstream segment. Access to productive clones, government stringent taxation policy on imported rubber feedstock, and a shift to machine-tapper and portable rubber processors are the immediately actionable solutions. Availing expandable rubber-related education programs for youths in smallholder families is critical to actualize technology-driven, and high-productivity farming for the segment to build back better. Continuous learning is mandatory to innovate, engage in the value chain, and multiply the current twin-loop circularity for the succession of dignified smallholders in sustaining the rubber industry.

Downloads