The Effect of Different Waste Material Binders in Relation to Khaya Senegalensis Solid Fuel Pellet Quality

DOI:

https://doi.org/10.37934/araset.32.3.151164Keywords:

Biomass, pelletization, solid fuel, fuel pellets, waste binder, pellet qualityAbstract

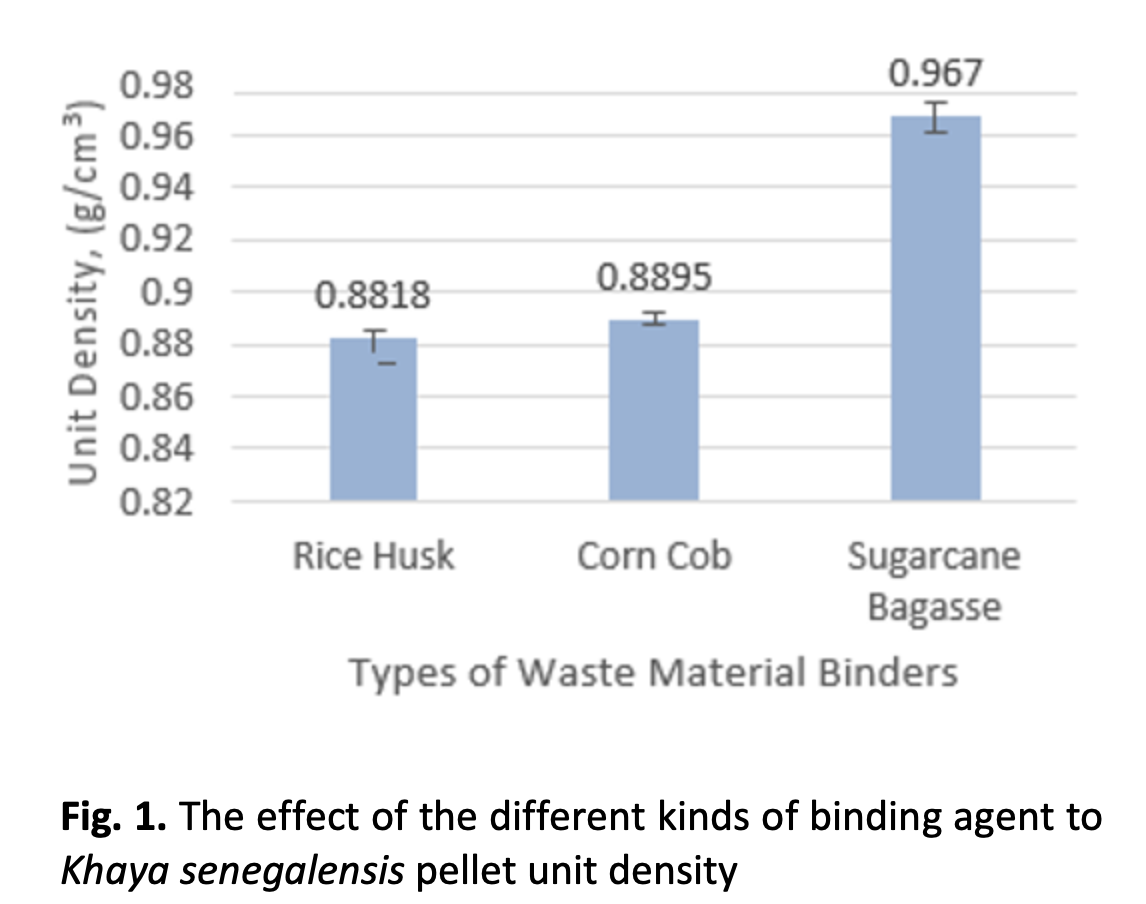

Fuel pellets are an attractive renewable energy source derived from biomass sources thanks to their uniformity and ease of handling. However, raw biomass and waste material binders have several drawbacks, which include poor physical properties, particularly low density and compositional heterogeneity, which restrict their wider use as a general source of energy. Besides, due to the low energy density, low bulk density, and uneven shape and size of raw biomass, it is very difficult to store and transport biomass in its original form, which decreases transport efficiency. This study investigated the effect of waste material binders (rice husk, corn cob, and sugarcane bagasse) on the mechanical and thermal properties of Khaya Senagalensis pellets. The mechanical and thermal properties were determined according to ASTM standards. Waste material binders have affected pellet quality such as density, bulk density, moisture content, durability, compressive strength, shatter index, water resistance, ash content, volatile matter, fixed carbon, and calorific value. From the analysis, sugarcane bagasse as a binder shows the highest quality pellet in terms of mechanical properties. Sugarcane bagasse produces the highest density (0.967g/cm3), bulk density (0.4094), durability (99.71%), shatter index (98.85%), water resistance (98.35%), and thermal properties, which are the highest volatile matter (94.71%) and the lowest ash content (1.71%). In a nutshell, sugarcane bagasse is a good binder that gives a positive impact to the K.senegalensis pellets in terms of storage and transportation compared to corn cob and rice husk binder.

Downloads