Design an Optimum Air Duct for Oscillating Water Column Wave Energy Device

DOI:

https://doi.org/10.37934/araset.34.1.164176Keywords:

Ocean wave energy, wave energy device, oscillating water column, low wave conditionAbstract

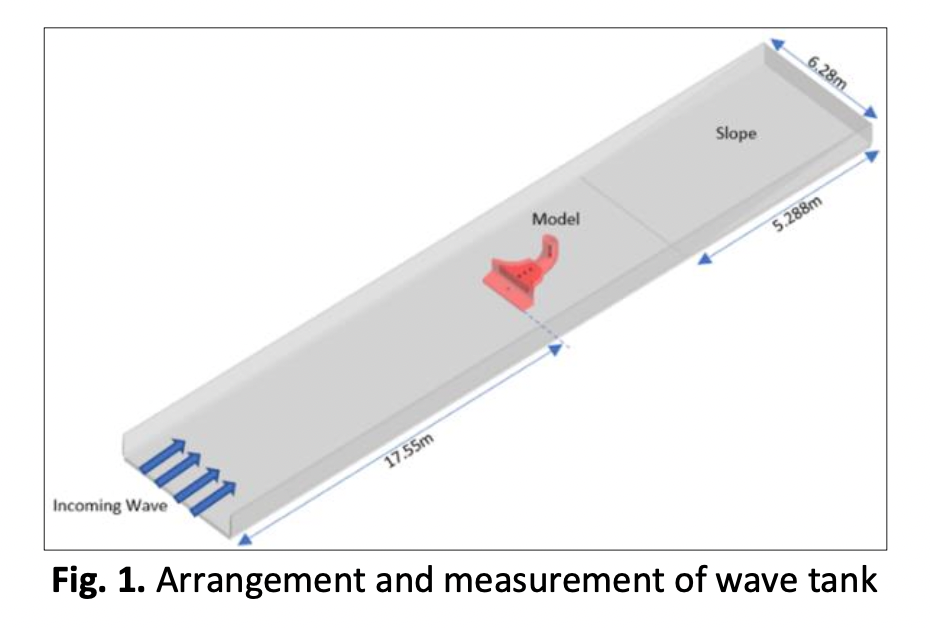

Oscillating Water Column (OWC) is a technology that harvests wave energy to generate electricity. It works by harnessing the wave-induced pressure oscillation in the opening mouth of OWC. The oscillation of the pressurised air is extracted using a turbine placed at the top of the OWC structure. Although OWC has been studied for many years, designing an optimum air duct for such devices is still an open research area. The air duct plays a crucial role in the energy conversion process, as it is responsible for directing the airflow towards the turbine, and its design can greatly affect the performance and efficiency of the system. The article aims to study how the air duct design impacts the power output form. Moreover, the result will be compared with the conventional air duct design. The OWC performance is analysed using Computational Fluid Dynamic (CFD) software to identify which shape of the air duct has high efficiency. Autodesk Inventor is used to design the OWC devices modified from the basis design. Then these designs are imported into CFD software to simulate and obtain the energy extraction result. The CFD software is chosen to simulate the hydrodynamics problem. In this study, the oval design shows significant improvement in the energy extraction performance compared to the basis design. The oval design managed to produce 9.81, 10.02, and 11.66 J/kg of mechanical energy compared to 9.81, 9.82, and 10.04J/kg as prompted by the basis air duct design at the wave height of 0.2505, 0.75, and 2.25m, respectively. The result shows that the non-edge produces higher air pressure than the sharp edge of the air duct shape. Thus, the oval air duct design is more efficient, and it may increase the performance of the OWC wave energy converter device at a low wave height of 0.75 m.

Downloads