Analysis of Physical and Mechanical Properties of Rice Husk-based Particle Board

DOI:

https://doi.org/10.37934/araset.31.3.4046Keywords:

Particle board, rice husk, compressive strength, flexural strengthAbstract

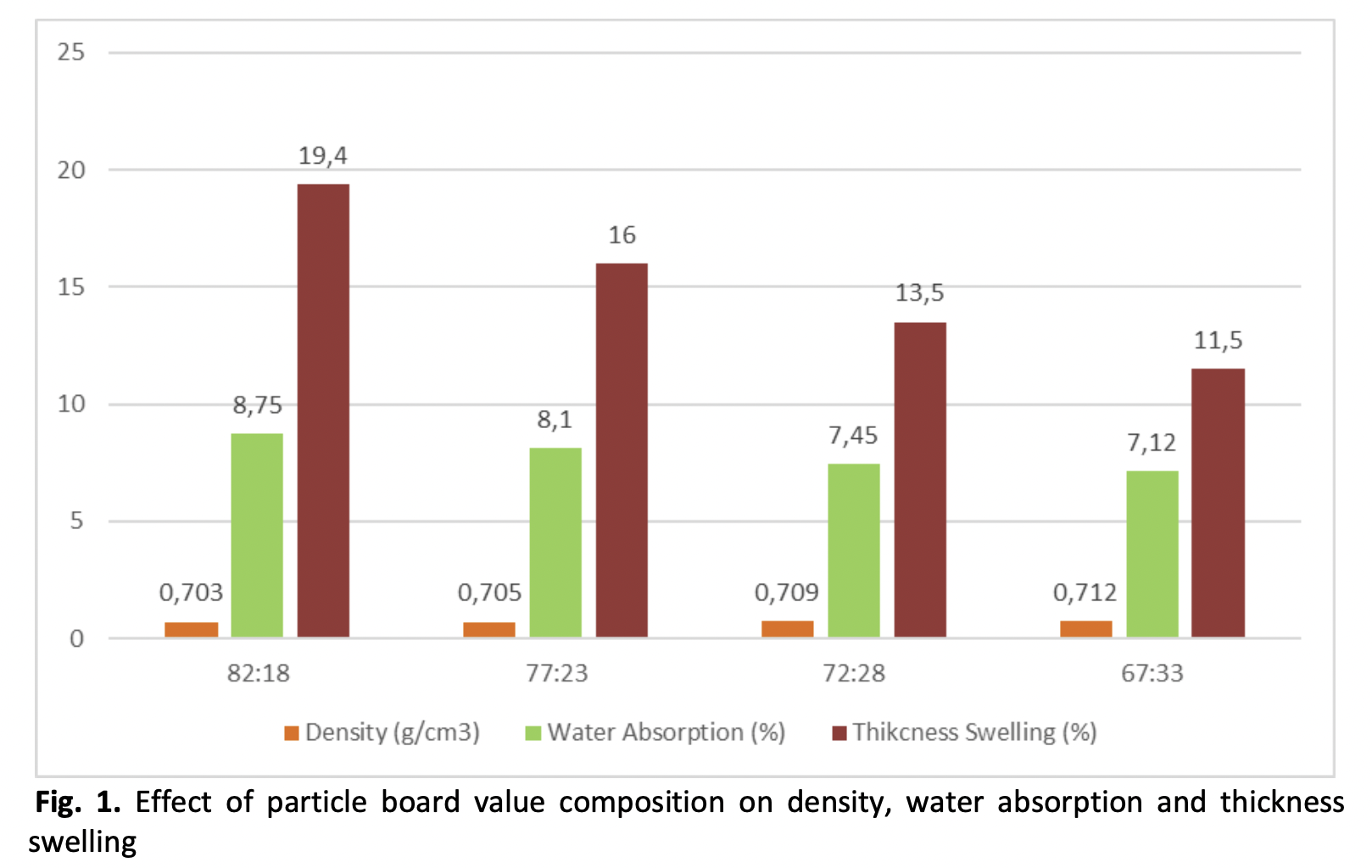

This study was conducted to determine the physical and mechanical properties of particleboard. Manufacture of particleboard utilizes raw materials of rice husk with epoxy resin. The composition variations of rice husk : Epoxy are, 82:18, 77:23, 72:28. The rice husk was soaked in 5% NaOH solution for 1.5 hours, then smoothed and filtered with a size of 20 mesh. After preparation, the rice husk and epoxy were mixed with their respective compositions. Then the hot forging process was carried out with a pressure of 25 kg/cm2 at a temperature of 140° C for 8 minutes. The results of density test was found from 0.703 - 0.712 g/cm3, the water absorption value from 7.12 % - 8.75% and the thickness expansion value from 11.5% - 19.4%. The compressive strength (MOR) values range from 56.105 -82.63 kgf/cm3 and the flexural strength (MOE) values range from 8695 kg/cm2 - 10470.49 kg/cm2.Downloads

Downloads

Published

2023-08-09

How to Cite

M. Milawarni, Sri Aprilia, Nasrullah Idris, E. Elfiana, Y. Yassir, Yasir Asnawi, … Nawawi Juhan. (2023). Analysis of Physical and Mechanical Properties of Rice Husk-based Particle Board . Journal of Advanced Research in Applied Sciences and Engineering Technology, 31(3), 40–46. https://doi.org/10.37934/araset.31.3.4046

Issue

Section

Articles