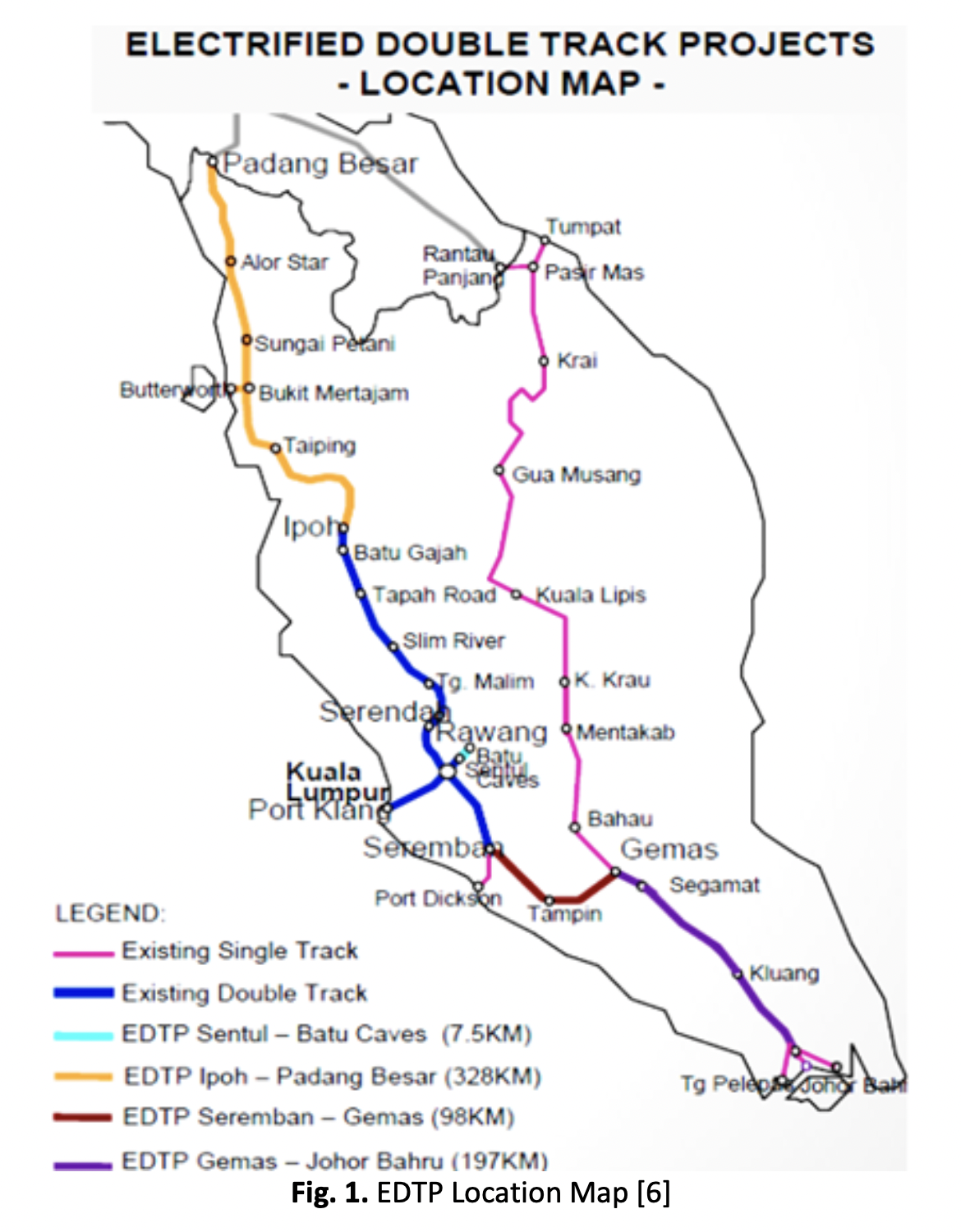

The Optimal Span Length of the Overhead Catenary System for the Gemas-Johor Bahru Electrified Double Track Project

DOI:

https://doi.org/10.37934/araset.43.2.148166Keywords:

Optimum span, OCS, GJBEDTP, Wind speed, Estimated costAbstract

The span term in the Overhead Catenary System (OCS) refers to the distance between two subsequent supports in the running track direction. Longer spans are preferable for economic reasons because they reduce the number of supporting structures. The maximum span along the track was suggested by OCS designers using a structure spacing table and chart with varying wind speeds and radius of curvature. The structure spacing chart is a logarithmic curve that is plotted based on the specifications of the project and design constraints. According to the current design, the maximum span length for the Gemas-Johor Bahru Electrified Double Track Project is 72 metres (GJBEDTP). The current OCS design can be upgraded to provide a greater maximum span. This study looked at the economic benefits of increasing the maximum span length of the GJBEDTP in terms of reducing the total number of supporting structures. The track is separated into many equal-length track sections, and their individual spans are selected using the wind study assessment report and the structure spacing chart. Divide the total track length by the average span to get the estimated total number of supporting structures. In this study, a graph showing the percentage of cost savings and the maximum allowable span is plotted. In this optimization issue, the Elbow approach is used to select a point where diminishing returns are no longer worth the extra expense of going for a longer span. According to the results, the maximum span of 72 m is the ideal span for the GJBEDTP.

Downloads