Experimental Analysis of Dual Inlet Cyclone Separator

DOI:

https://doi.org/10.37934/araset.28.1.149160Keywords:

Cyclone separator, separation efficiency, inlet geometryAbstract

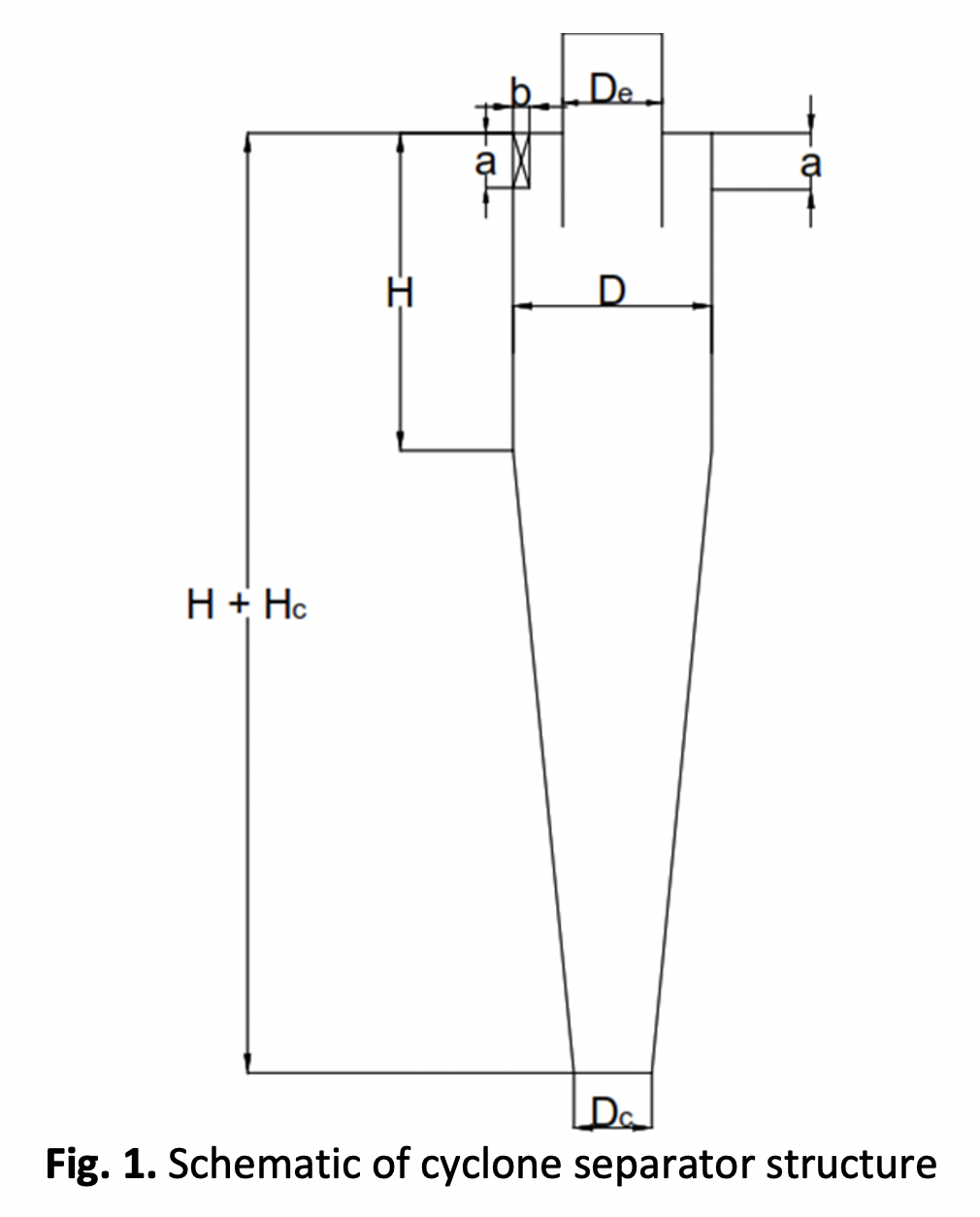

Cyclone separators are suitable to remove particles in extreme conditions with high pressure and temperature during the gas-solid separation process. The important performance of cyclone separators is determined by the separation efficiency and pressure drop. The inlet parameters including the number of inlets, inlet geometry and inlet gas velocity affects the performance of cyclone separators. In this paper, the experimental investigation has been conducted to determine the effects of dual inlet to the separation efficiency of cyclone separators. The cyclone separator was fabricated using the acrylic materials to accommodate the flow observation and trajectories inside the chamber. The experiments were conducted at 9, 11 and 13 m/s of inlet velocity using three particle sizes at 277.5, 42.5 and 625 um. Results showed that as the particle sizes increases, the separation efficiency also increases up to 94.5% for 625 um particles. The findings indicate that the dual inlet cyclone separators increases the performance of cyclone separators especially to remove fly ash in the biomass processing plant and other gas-solid process.Downloads

Downloads

Published

2022-10-01

How to Cite

Amirul Baharuddin, Shahrin Hisham Amirnordin, Adam Kasani, Mohd Faizal Mohideen Batcha, & Muhammad Rafiuddin Wahidon. (2022). Experimental Analysis of Dual Inlet Cyclone Separator . Journal of Advanced Research in Applied Sciences and Engineering Technology, 28(1), 149–160. https://doi.org/10.37934/araset.28.1.149160

Issue

Section

Articles