Thrust Force for Drone Propeller with Normal and Serrated Trailing Edge

DOI:

https://doi.org/10.37934/arfmts.101.1.160173Keywords:

Malignant tumor, heat propagation, CFDAbstract

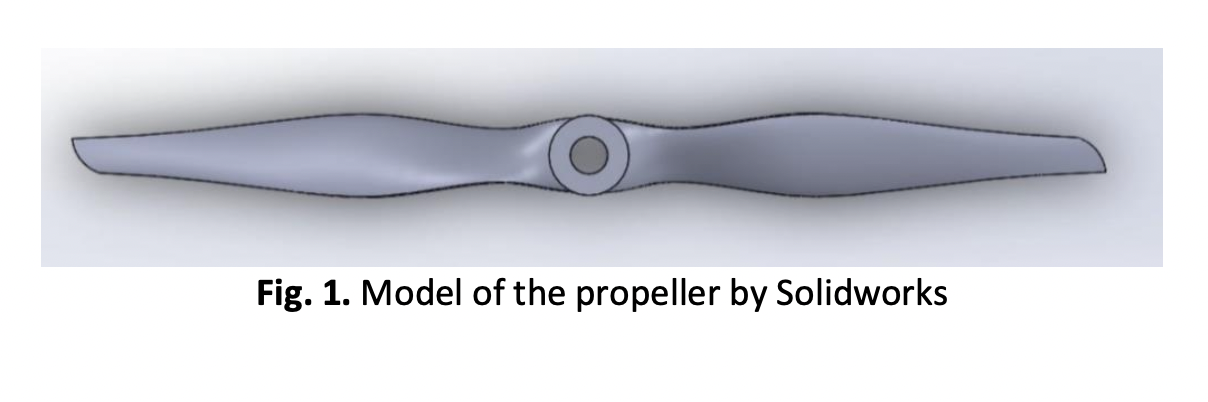

The drone becomes more recognized in the civilian sector; the drone's popularity becomes increases as time goes by. Nevertheless, despite the excitement of flying drones, several types of issues occur caused by the drone. In some circumstances, the aeroacoustics noise is a big concern, and quiet drone propellers would be more environmentally friendly to the surrounding area. Moreover, the noise from the drone can be a nuisance for the surrounding population and animals. Therefore, a solution needs to be proposed to reduce the sound level produced by the drone so that drone can be piloted in a surrounding area without breaking any noise level limit set by the government. Hence, the propeller's serrated trailing edge type is the proposed solution to this problem. The serrated trailing edge propeller can reduce several drone noise decibels based on past research. Thus, an investigation is conducted to study the thrust force between the normal propeller and the serrated propeller. The aerodynamic performance of the serrated propeller is analysed using computational fluid dynamic simulation and compared to that of the normal propeller. Ansys Fluent 2021 is used to solve the dependable RNG k-epsilon turbulence model. The thrust force, thrust coefficient, and lift coefficient operating on both propellers were all simulated. The results obtained by the transient approach for propellers have been validated by earlier experimental studies.

Downloads