Numerical Simulation on Heat Transfer Performance of a Liquid Cold Plate for Cooling of the Electric Vehicle Battery

DOI:

https://doi.org/10.37934/arfmts.102.1.114125Keywords:

Heat transfer, liquid cold plate, electric vehicles (EV), batteryAbstract

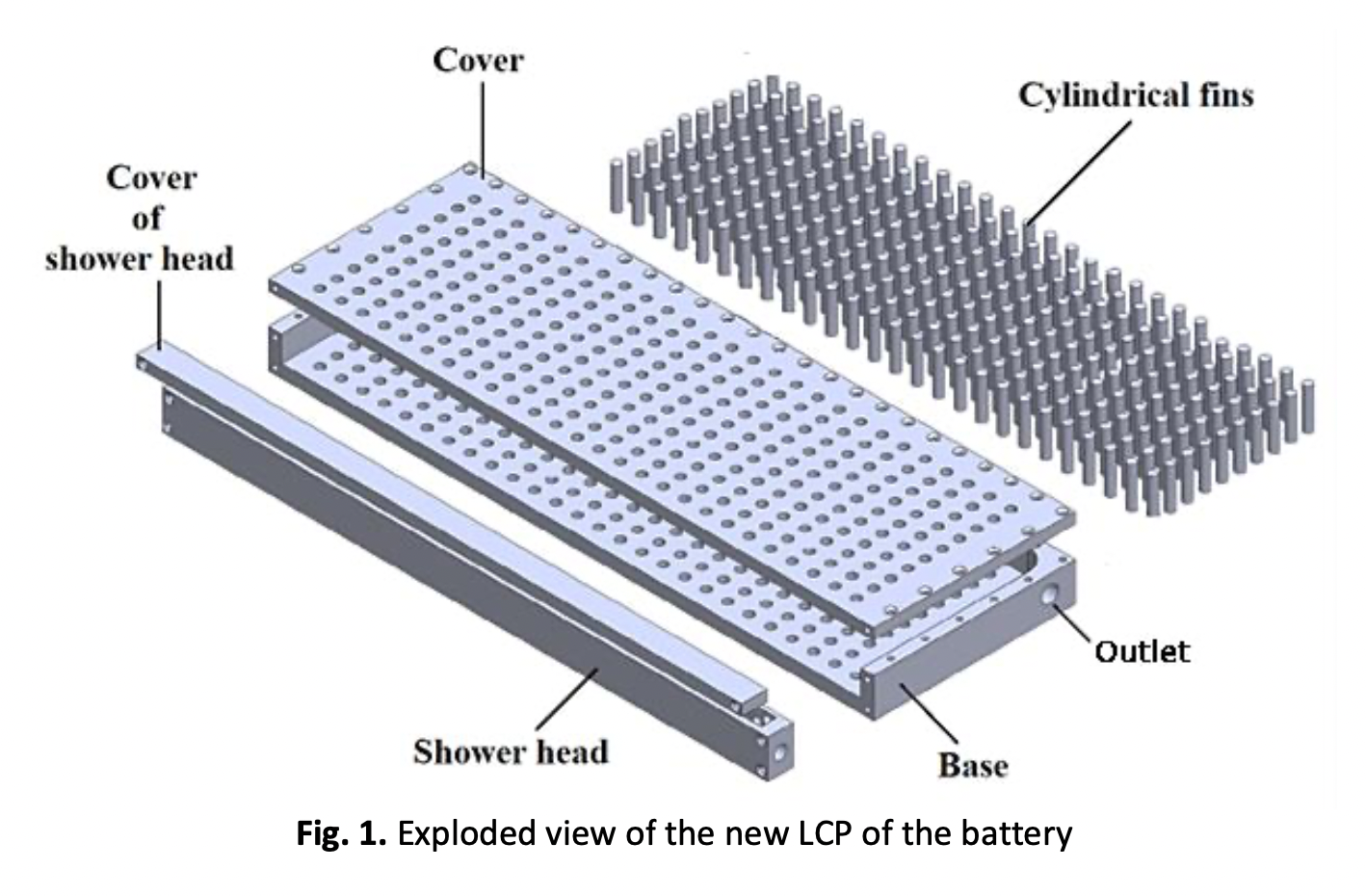

Around the world, there is a significant increase in the number of electric vehicles on the roads. Among the reasons are the aims to reduce the global dependency on oil as an energy source due to its political and economic dimensions especially for the non-oil producing countries by maximizing the use of electric vehicles. At the same time, it is also due to global concerns for the environmental aspect, especially global warming where transportation represents 30% of it. The battery is considered the main source of power for electric vehicles, but the battery tends to generate a significant amount of heat due to internal resistance during operation. The generated heat during the charging/discharging processes could lead to overheating in the battery which could end in battery failure. Therefore, dissipating the generated heat in the EV battery becomes essential through thermal management systems to ensure that the battery operates within a safe temperature range. Hence, the present study aims to introduce a new design of the liquid cooling system and also to investigate the effective parameter which affects its heat transfer performance. This paper is part of the overall study and describes the computational fluid dynamics by using ANSYS FLUENT software and numerical analysis to investigate the effect of the inlet/outlet arrangements on the heat transfer performance of a new LCP used for cooling the EV battery cell. There are three inlet/outlet arrangements: I-arrangement, Z-arrangement, and L-arrangement. The flow rate range of the present study is at the range of 0.4 – 1.6 l/min under 300 W heat flux. The L-arrangement has the best cooling performance compared to I-arrangement and Z-arrangement, where it achieves an average battery cell temperature which equals to 37.1 ⁰C along flow rates, while it is at 43.3 ⁰C and 38.0 ⁰C for I-arrangement and Z-arrangement, respectively. The temperature uniformity for both L-arrangement and Z-arrangement is almost similar, and they achieved good temperature uniformity at all flow rates, while I-arrangement failed to achieve good temperature uniformity at the lowest flow rates.

Downloads