Analysis of Inlet Temperature and Airflow Rate on Drying Process in a Spray Dryer Using Computational Fluid Dynamics Method

DOI:

https://doi.org/10.37934/arfmts.94.1.163171Keywords:

Spray dryer, drying chamber, CFD, temperature, airflow rateAbstract

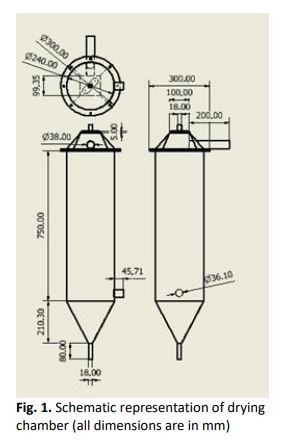

Spray drying is a method of producing a dry powder from liquid or slurry by rapid drying with a hot air. The spray drying process consists of atomizing the liquid into fine droplet, contacting the hot air with the droplets, drying droplets by the formation of solid particle agglomerates and separating solid products. This research was carried out to analyse the drying process parameter of spray dryer to reach the fluid drying temperature of around 100°C in which the drying process is assumed to be successful. Simulation using computational fluid dynamics method was performed. Air and water were employed as the working two phase fluids injected into the drying chamber at various inlet temperatures and airflow velocities. RNG k-ɛ and k-ω were used to solve drying process phenomenon in the drying chamber. In this work, the inlet air temperatures and the airflow velocities were varied from 175°C to 225°C and 1.5 m/s to 3 m/s, respectively. The results showed that the higher inlet air temperature, the greater the outlet temperature. In addition, the outlet temperature also increased with the increase of airflow velocity. Under the condition investigated, the optimal parameter was found at inlet temperature of 225°C and airflow velocity of 3 m/s. This condition is expected in avoiding the failure of spray drying process.

Downloads