Hydrodynamic Analysis Inside a Circulating Fluidized Bed Boiler Based on Time Change Using CFD

DOI:

https://doi.org/10.37934/arfmts.103.1.133149Keywords:

CFB boiler, CFD, turbulence model, time change dataAbstract

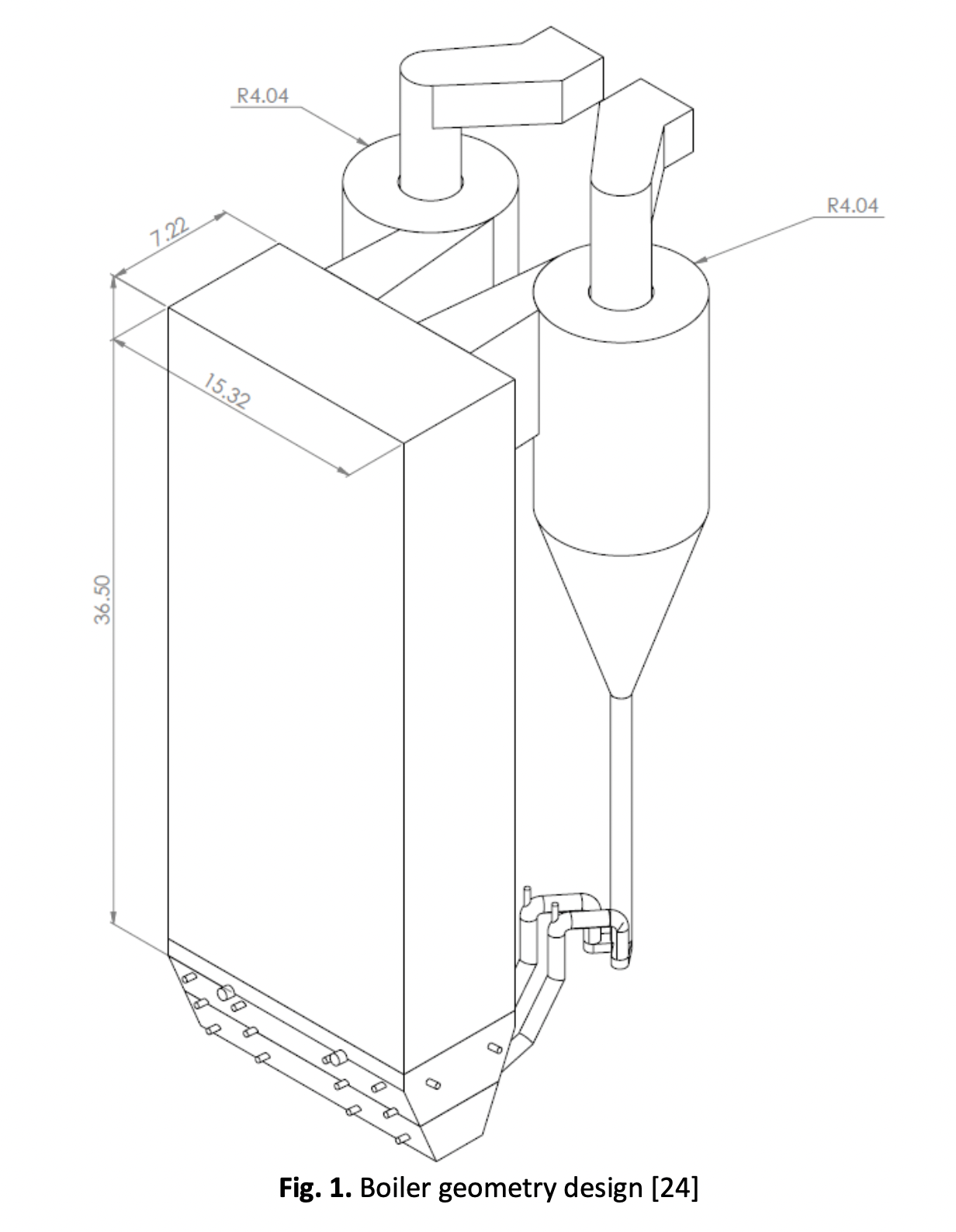

The power generation industry has progressively improved the design of power plants to tackle global climate change. Coal-fired power plants will be cleaner and more efficient with the CFB (Circulating Fluidized Bed) technology in the boiler. CFB boilers have the advantage where the resulting carbon dioxide, SOx, and NOx emissions are significantly reduced. This makes research on CFB boilers widely carried out, especially those using CFD (Computational Fluid Dynamic). This study aims to determine the most appropriate turbulence model using CFD simulations on CFB boilers to analyze the hydrodynamic elements in the boiler against time changes, including the distribution of solid volume fractions, pressure, velocity, and wall shear stress. Three turbulence models were tested as part of the simulation: standard , RNG , and RSM, which were then compared to earlier research. The RNG model produces the closest result to the experimental data, with an error value of 6.24%. Solid volume fraction area is increasingly widespread with values ranging from 0.05 to 0.1 from the furnace’s bottom to a height of 15 m. The high-pressure area further expands at the bottom of the furnace to a height of 15 m, with values ranging from 3 kPa to 10 kPa. The outlet line velocity has increased from 43 m/s to 50 m/s. The wall shear stress increases from 0.75 Pa to 1.1 Pa at the outlet wall.

Downloads