Fluid and Structure Analysis of Wind Turbine Blade with Winglet

DOI:

https://doi.org/10.37934/arfmts.90.1.80101Keywords:

Wind Turbine, Blade Design, Winglet Configuration, Surface Response, Structural Analysis, Numerical SimulationAbstract

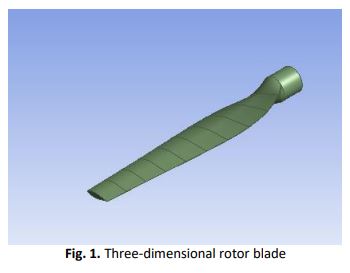

One of the succeeded methods to enhance the performance of horizontal axis wind turbine (HAWT) is an attaching a winglet to the blades tip. The current paper study the effect of four key parameters that are used to describe the winglet on the performance of wind turbine which are winglet height H%R, cant angle θ, twist angle β, and taper ratio Λ. A five design cases for each geometric parameters were numerically investigated using computational fluid dynamics (CFD) by ANSYS18.1 software, which totally give a twenty different response. A validation of present computational model with reference experimental results successfully carried out with maximum inconsistency of 3%. A mathematical correlation was established from the CFD results and being used in predicting the turbine power for the different winglet geometric parameters. From CFD and mathematical correlation response, the effect of H and θ were greater than β and Λ on the turbine power. The epoxy E-glass unidirectional material was selected for current study to investigate the effect of winglet on blade structure. The power increases by 2% to 30% due to adding winglet to a wind turbine blade. The maximum power increment corresponds to the design case of W6 with H= 8%R, =30°, β = 3°, and Λ = 0.8. Form the structural analysis the addition of winglet changes the stress distribution over the blade, increasing stresses at the blade root, and achieved the transfer of the maximum deformation from the blade tip to the winglet tip.

Downloads