Feasibility of Pico Scale Turgo Turbine Blade Manufacturing Method Using Three-Dimension Printer Technology

DOI:

https://doi.org/10.37934/arfmts.107.1.190201Keywords:

Turgo turbine, triangle velocity, blade, 3D printerAbstract

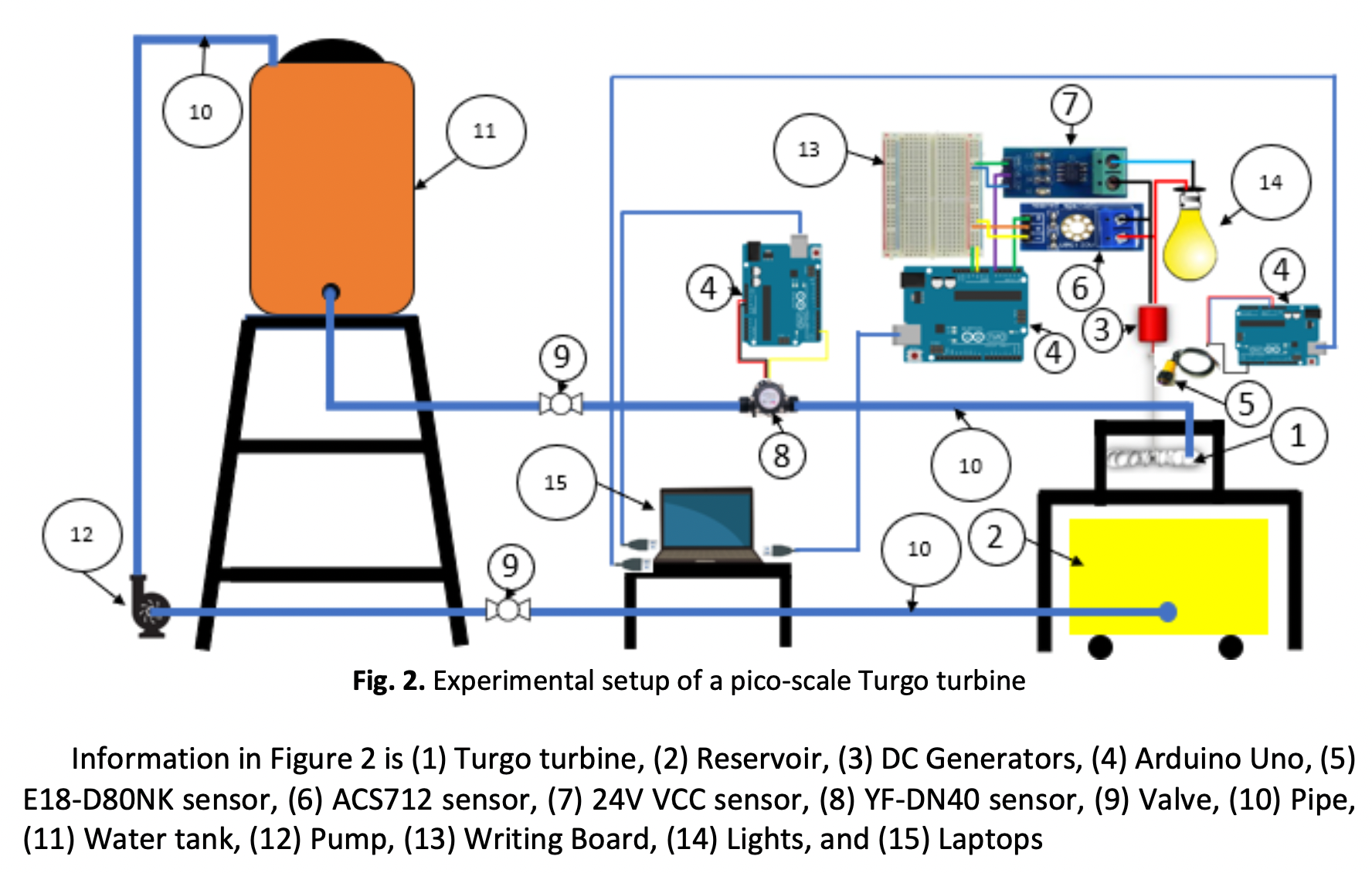

This study proposed the design of pico-scale Turgo turbine blades using triangle velocity and printing blades using three-dimensional (3D) printer technology. Then, describe the testing method of Pico scale Turgo turbines in laboratory conditions. The velocity triangle analysis accommodates backflow where it is affected by blade angle; this is relevant to the Turgo turbine because the flow and blades have an angle so that the estimated change in momentum approaches real conditions. Based on calculation results, the geometry of the pico-scale Turgo turbine blades that produce maximum performance is as follows: angle of attack is 20°, inlet blade angle is 40°, outlet blade angle is 10°, and radius blade angle is 15°. Then, simulation results determine the potential water power that the blade is capable of receiving is 17.5 W. The experimental setup has a potential water power of 14.81 W, lower than the mechanical strength simulation results. From the experimental results, the performance maximum is 0.092; the average deviation between the analytical and experimental is 4%. Therefore, the manufacture of pico-scale Turgo turbine blades using 3D printer technology is considered because of the ease of the manufacturing process, the time needed in the manufacturing process is short, and the cost is low.

Downloads