Fluid Viscosity Measuring Instrument with Internet of Things (IoT) Based Rotary Method

DOI:

https://doi.org/10.37934/arfmts.92.1.6589Keywords:

Viscometer, Rotary Method, Simulink Matlab, Monitoring, IoTAbstract

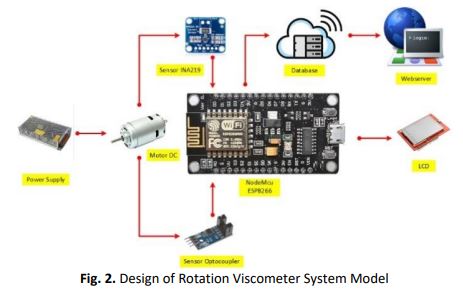

The viscometer is a system measuring the viscosity value of a liquid substance. The function of this viscosity measuring instrument is used to analyze the viscosity level of a particular product so that it is easy to know the quality of fluid viscosity. In this research, two methods were conducted, namely simulation and experimentation. Simulations were conducted using Simulink Matlab while experiments were conducted by designing fluid viscosity measuring instruments by rotary method or commonly known as a rotational viscometer. This tool uses two sensors namely, rpm sensor to measure rpm of dc motor and current and voltage sensor to measure current from dc motor, and also use controller equipped with Internet of Things (IoT) so that the measurement results will be displayed through LCD and can be monitored through the website. From the simulation results obtained drum motor spinning at low speed to the 10th second of the motor rotation about 6 rad / s and as time increases, the motor rotation will increase until the 60th second of the motor rotation begins to be constant this is due to the large shear voltage produced by a fluid at the beginning of the motor is turned on very large and decreases over time. While the test results of the tool that has been designed, obtained the measurement results on SAE 40 Oil obtained accuracy results of 0.99, on the measurement of SAE Oil 20W-50 obtained an accuracy value of 0.99 and in the measurement of SAE 10W-30 Oil obtained an accuracy value of 0.99.

Downloads