CFD Simulation Using ANSYS FLUENT of Jet Nozzle of Ethanol at Temperature of 360 K

DOI:

https://doi.org/10.37934/arfmts.96.1.168178Keywords:

CFD, elevated temperature, thermal energy, ethanol, spray nozzleAbstract

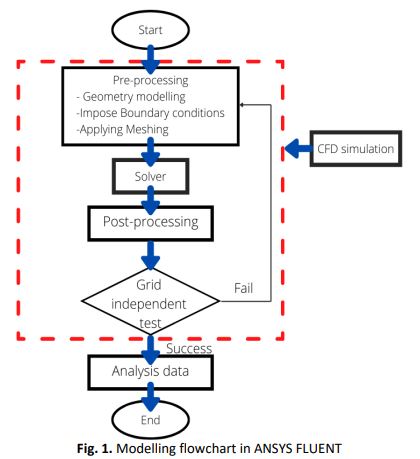

Spray coating technology is an advanced manufacturing process to break the liquid down into small droplets and disperse these droplets uniformly on the target substrate. The nozzle used in this fabrication process rapidly disintegrates the liquid jet at a direction of motion governed mainly by the prevailing airflow pattern in the spray region environment. According to Navier–Stokes energy equation, the fluid and environmental temperature capable of supplying additional energy to the droplet imparted the ejected liquid jet from the nozzles. With a view to understanding the liquid droplet behaviour at elevated temperatures, this study investigates the jet velocity, pressure, and temperature of ethanol at its evaporation temperature of 360 K using commercial CFD software (ANSYS FLUENT 2020). A numerical simulation of a simple nozzle system with a cone angle of 56° and an outlet radius of 0.1966 mm was modelled at 1 bar inlet pressure to study the effect of the environment temperature on the liquid jet. The result from the temperature profile showed that the liquid jet exhibited turbulence or a swirling effect at elevated temperature as the liquid absorbed thermal energy. The liquid jet temperature increased to the maximum temperature of +3K at a liquid jet distance of 10 cm when compared with normal environment temperature. This numerical study showed that environmental conditions such as temperature can impact the liquid jet quality and properties, which are difficult to observe during experimental work. It is expected that the finding from this work would benefit the industries, leading to better spray nozzle design for future coating applications.

Downloads