Experimental Study on Heat Transfer Improvement in a Circular Passage Using Metal Oxide and Ethylene Glycol Based Well Stable Nanofluids

DOI:

https://doi.org/10.37934/arfmts.98.2.90105Keywords:

Nanofluids, mass flow, circular passage, metal oxides, characterizationsAbstract

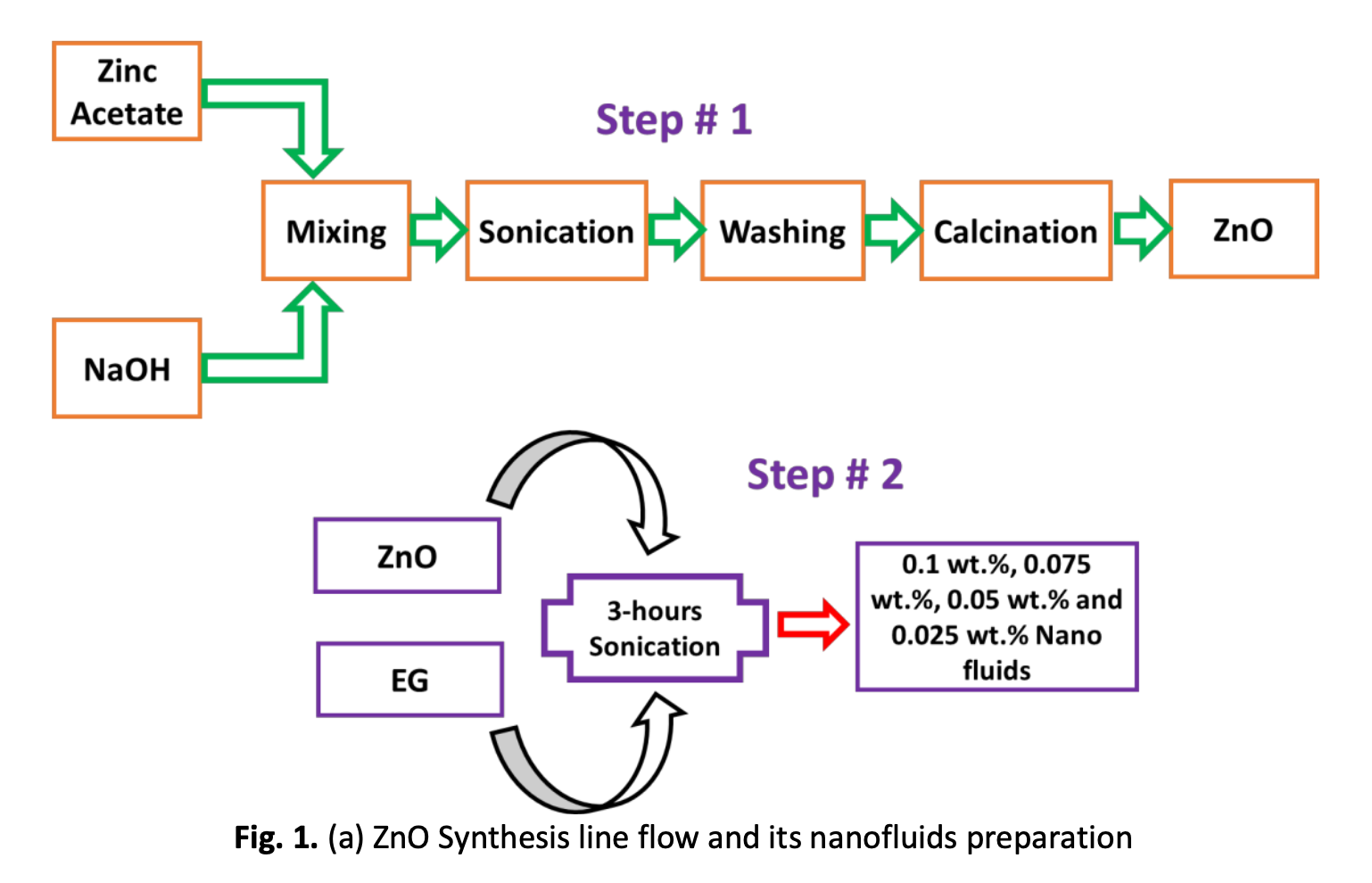

Zinc Oxide @ Glycol based nanofluids was prepared using the ultra-sonochemical technique and 2 step methods. The heat convection characteristics of as prepared nanofluids were observed for a closed single conduit in turbulent flow regimes. The prepared nanofluids were characterized for UV-vis, FTIR, XRD, FESEM, and TEM analysis to confirm the accurate synthesis of ZnO nanoparticles. Analytical data related to heat transfer properties of the synthesized nanofluids for the heat exchanger, incorporated with the conduit test section were collected. The addition of ZnO solid nanoparticles in the Ethylene Glycol enhanced the value of thermal conductivity and other thermo physical characteristics of the nanofluids. Supreme thermal conductivity was recorded at 45°C for using 0.1 wt.% of Zinc Oxide @ Glycol based nanofluids. Adding more wt.% of the ZnO solid nanoparticles in the Ethylene Glycol increased the thermal conductivity subsequently with variations in temperature from 20 to 45ºC. Furthermore, Nusselt numbers of Zinc Oxide @ Glycol based nanofluids were calculated at different wt.% of ZnO present in Ethylene Glycol base fluid. The occurrence of ZnO nanoparticles into the Ethylene Glycol base fluid intensify the Nusselt (Nu) number by 51.5%, 43.79%, 38%and 24.06% for 0.1 wt.%, 0.075 wt.%, 0.05 wt.% and 0.025wt.% concentrations, respectively. Varying wt.% of ZnO (0.1 wt.%, 0.075 wt.%, 0.05 wt.%). The absolute average heat transfer of Zinc Oxide @ Glycol based nanofluids using at the highest concentration of 0.1 wt.% was enhanced compared to the Ethylene Glycol base fluid. The magnitude of absolute average heat transfer was increased from 600 W/m2k for the EG@DW mixture to 1292 W/m2k for Zinc Oxide @ Glycol based nanofluids. Correspondingly, the heat transfer development at the other three (0.075 wt.%, 0.05 wt.%, and 0.025 wt.%) was observed as 600–1167, 600–1010 and 600–970 W/m2k, respectively, which is superior to pure Ethylene Glycol base fluid.

Downloads