Thermal and Static Properties Investigation of Different Intake Manifold Materials to Lower Air Intake Temperature for Improved Engine Performance

DOI:

https://doi.org/10.37934/araset.30.2.112Keywords:

Intake Manifold, Composite Materials, Alloy Materials, Static Analysis, Thermal Analysis, Modal Analysis, FSAEAbstract

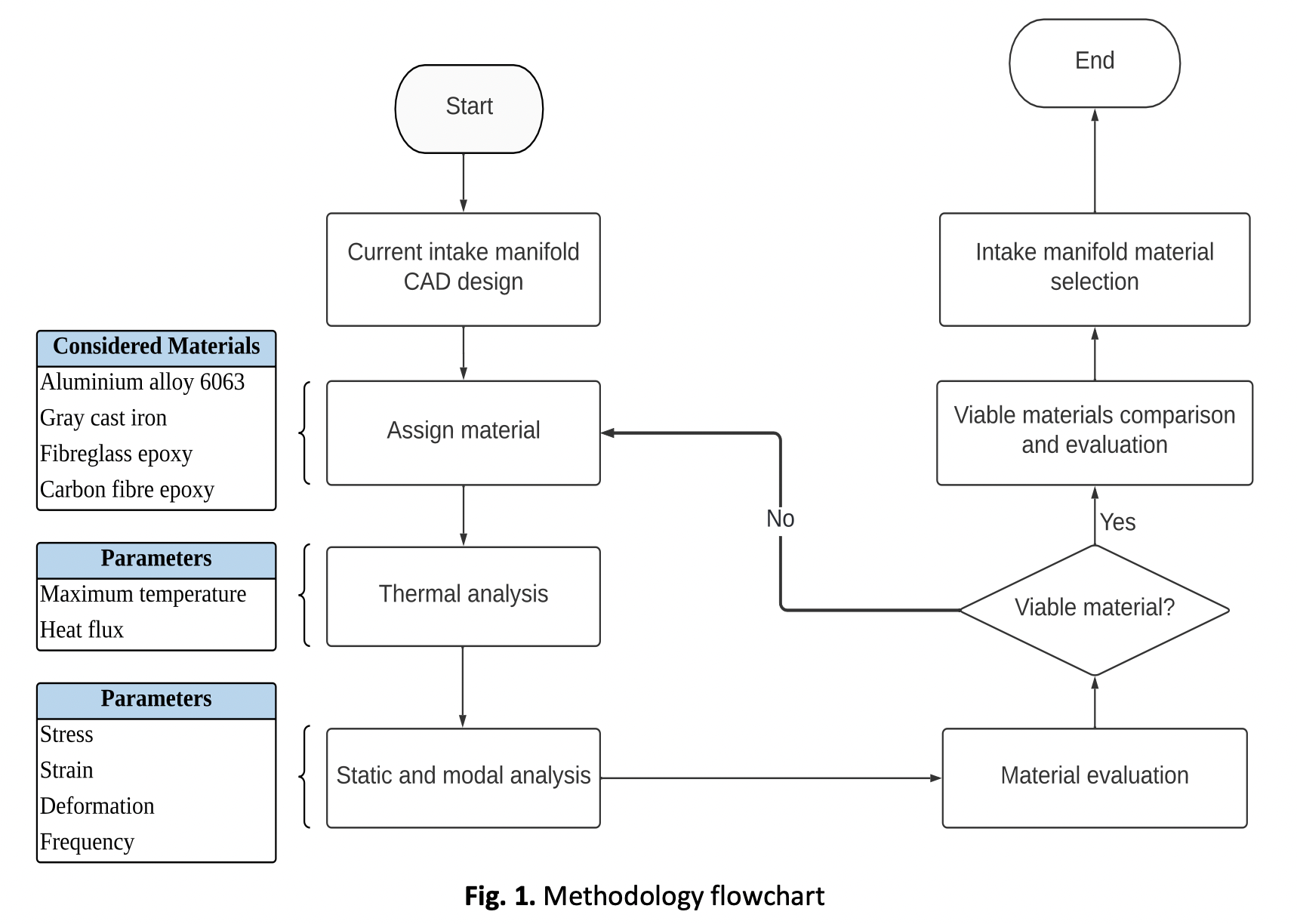

Formula SAE competition is targeted at students who are interested in designing and developing a Formula-type race car. Rules were imposed to restrict the car’s performance for safety besides encouraging problem-solving skills. One such rule is the requirement of a 20mm restrictor inserted between the carburettor and intake manifold to reduce the air intake. With a constricted airflow creating a bottleneck effect, less air will be provided to the engine for combustion, consequently reducing engine efficiency. The purpose of this project is to overcome this problem despite the restriction imposed by the rules. This is done by choosing an intake manifold material that provides a low air temperature while withstanding the stress and vibrations from the engine. Computational Fluid Dynamics (CFD) software was used to conduct the static, thermal and modal analysis of Aluminium Alloy 6063, Gray Cast Iron, Fibreglass Epoxy and Carbon Fibre Epoxy to choose the material that produces lower intake air temperature while maintaining high strength. Carbon fibre epoxy was found to provide the best durability against static stress while maintaining a lower intake air temperature compared to the other materials tested.

Downloads