Investigation on Cooling Channel in Hot Press Forming Through Numerical Simulation

Keywords:

Ultrahigh Strength Steel, Hot Press Forming, Cooling Channel Design Parameters, ANSYS FluentAbstract

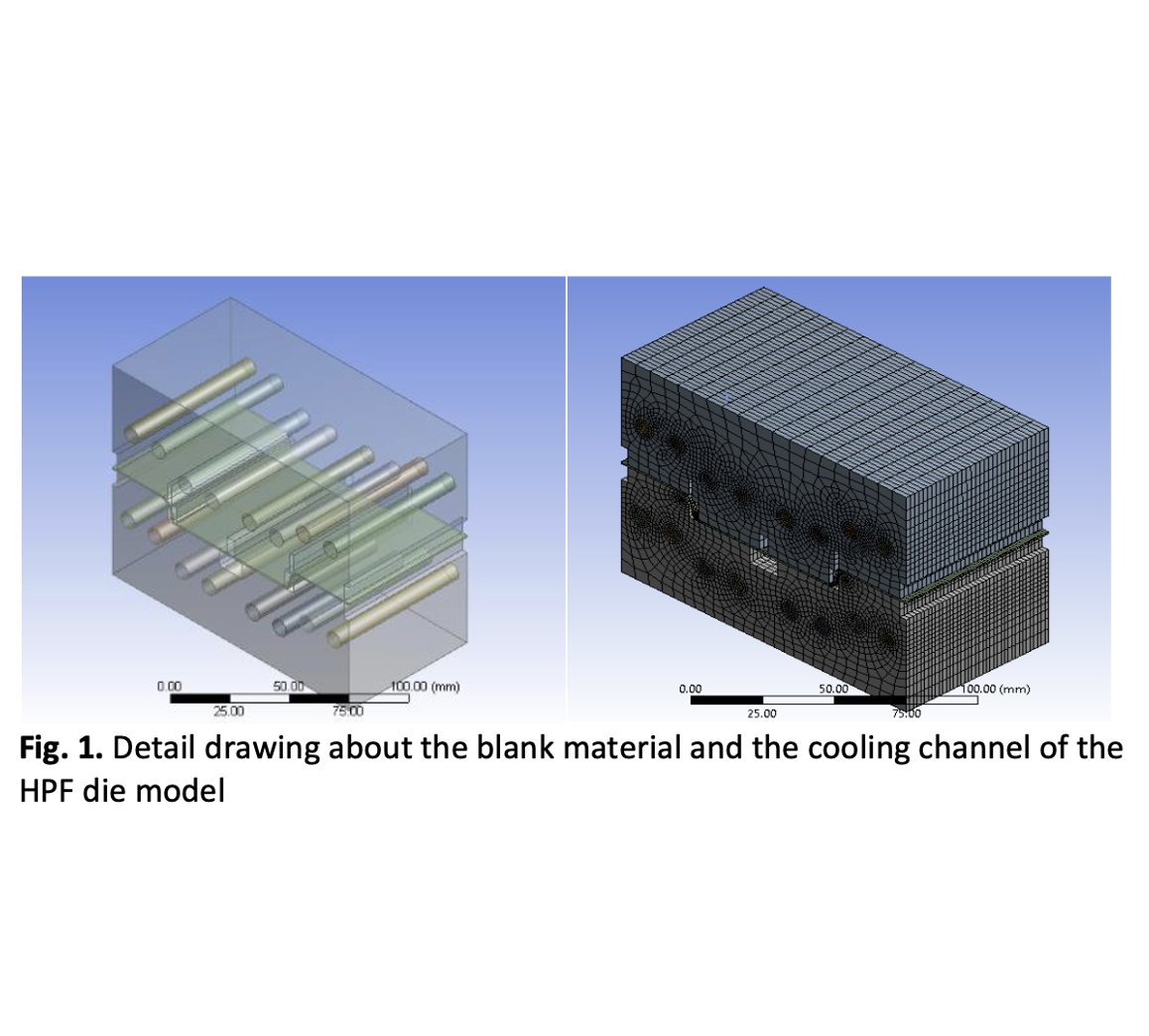

Quenching process in the hot press forming process was important in ensuring the sheet metal undergoing effective rapid cooling simultaneously with the stamping process. Efficient quenching will harden the sheet metal by transforming its microstructure from austenite to martensite. Studies on quenching process through numerical simulation was highly favorable in obtaining optimized parameters for manufacturing-used. This can avoid waste production during the HPF process and reduce the time consumption from real life experimental work. In this paper, the process and the details of the hot press forming process was reviewed based on previous reference journal. The parameters varied in the paper such as forming temperature and the blank holding force was explained in term of its effect on the process. The effect of cooling channel design parameter in the hot press forming die such as the cooling duct diameter, the shape and the surface distance were also discussed and overviewed. Lastly, the research has concluded the more biggest size diameter with circular shape and nearest to the location of cooling channel was proposed to the best cooling rate and the most economical.