Thermo-hydrodynamic Analysis of Multistep Journal Bearing using Computational Fluid Dynamics Simulation

DOI:

https://doi.org/10.37934/cfdl.15.12.117134Keywords:

CFD, multistep journal bearing, viscosity, eccentricity ratio, temperatureAbstract

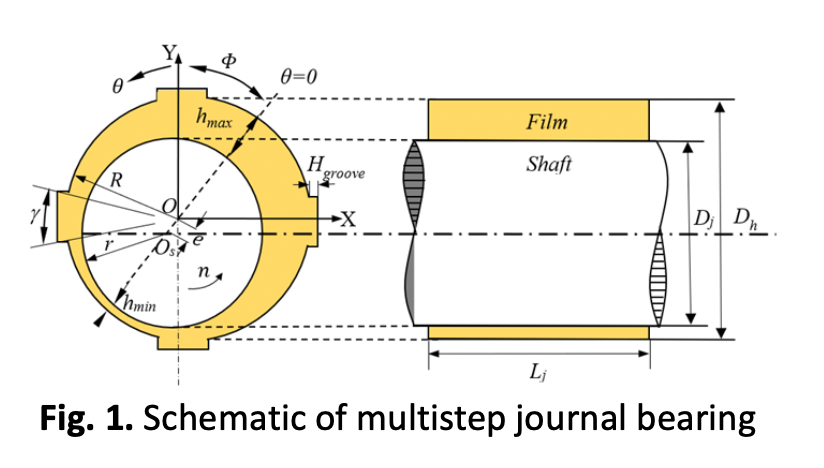

Journal bearing is a machine element that is used to maintain the continuous rotation of the shaft on its axis. The rising demand for efficient and economical journal bearing applications has resulted in increased demand for high-speed machines. An increase in engine speed raises the distribution of pressure, temperature, and vapor volume fraction. Most of the research still only focuses on increasing pressure distribution and load-carrying capacity. However, the value of friction force, temperature distribution, and vapor volume fraction must also be considered such that the lubrication of the journal bearing is close to the real situation. Therefore, the research was conducted by varying the geometry modelling through multistep textures using viscous boundaries and thermo-hydrodynamic lubrication. Owing to the high load and speed usage on multistep journal bearings, research on the effect of eccentricity ratio and inlet and outlet temperatures on the tribological performance of multistep journal bearings was conducted. The analysis has been performed using a multistep journal bearing modelling 3D computational fluid dynamics considering the effect of cavitation on temperature. The results of this study indicate that the use of multistep textures on journal bearings can reduce friction force, temperature, and vapor volume fraction. The variation of the eccentricity ratio shows that a high eccentricity ratio leads to a high three parameters (i.e., friction force, temperature, and vapor volume fraction). Finally, for variations of inlet and outlet temperatures, such parameters are high when the inlet and outlet temperatures are high.

Downloads

References

Lu, Xiaobin, and Michael M. Khonsari. “An experimental investigation of dimple effect on the stribeck curve of journal bearings.” Tribology Letters 27, no. 2 (2007): 169-176. https://doi.org/10.1007/s11249-007-9217-x

Bompos, Dimitrios A., and Pantelis G. Nikolakopoulos. “Tribological design of a multistep journal bearing.” Simulation Modelling Practice and Theory 68 (2016): 18-32. https://doi.org/10.1016/j.simpat.2016.07.002

Chen, Yu, J. Feng, Y. Sun, X. Peng, Q. Dai, and C. Yu. “Effect of groove shape on the hydrodynamic lubrication of journal bearing considering cavitation.” Engineering Computations 37, no 5 (2020): 1557-1576. https://doi.org/10.1108/EC-06-2019-0287

Dhande, D. Y., and D. W. Pande. “A two-way FSI analysis of multiphase flow in hydrodynamic journal bearing with cavitation.” Journal of the Brazilian Society of Mechanical Sciences and Engineering 39, no. 9 (2017): 3399-3412. https://doi.org/10.1007/s40430-017-0750-8

Tauviqirrahman, Mohammad, P. Paryanto, B.O. Pugastri, A.P. Hamonangan, M. Muchammad, E. Yohana, and J. Jamari. "CFD analysis of hydrodynamic journal bearing with Bingham plastic lubricant considering roughness." Cogent Engineering 10, (2023): 1-16. https://doi.org/10.1080/23311916.2023.2213537

Muchammad, M., M. Tauviqirrahman, L. Mario, and J. Jamari. "Thermo‑hydrodynamic analysis of multistep texture effect on the performance of journal bearings through acoustic and tribological characteristics." Journal of the Brazilian Society of Mechanical Sciences and Engineering 44, no 310 (2022): 1-13. https://doi.org/10.1007/s40430-022-03622-8

Muchammad, M. Tauviqirrahman, F. Risqulah, B. Setiyana, and J. Jamari. "CFD Analysis of Single Open Pocket and Multi Textured Surface in Hydrodynamic Lubrication Performance of Thrust Bearings." AIP Conference Proceeding 2706, no. 020016 (2023): 1-6. https://doi.org/10.1063/5.0120208

Cupu, Dedi Rosa Putra, and Kahar Osman. "Numerical analysis of the effect of temperature on the pressure and film thickness for line contact elastohydrodynamic lubrication using bio-based oils as lubricants." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 92, no. 1 (2022): 90-104. https://doi.org/10.37934/arfmts.92.1.90104

Jang, G. H., and D. I. Chang. “Analysis of a hydrodynamic herringbone grooved journal bearing considering cavitation.” Journal of Tribology. 122, no. 1 (2000): 103-109. https://doi.org/10.1115/1.555333

Jang, G. H., and J. W. Yoon. “Nonlinear dynamic analysis of a hydrodynamic journal bearing considering the effect of a rotating or stationary herringbone groove.” Journal of Tribology 124, no. 2 (2022): 297-304. https://doi.org/10.1115/1.1401019

Singh, U., L. Roy, and M. Sahu. “Steady-state thermo-hydrodynamic analysis of cylindrical fluid film journal bearing with an axial groove.” Tribology International 41, no. 12 (2008): 1135-1144. https://doi.org/10.1016/j.triboint.2008.02.009

Kotnurkar, Asha S., and Joonabi Beleri. "Peristaltic transport of ellis fluid under the Influence of viscous dissipation through a non-uniform channel by multi-Step differential transformation method." Journal of Advanced Research in Numerical Heat Transfer 9, no. 1 (2022): 1-18.

Nashee, Sarah Rabee, and Haiyder Minin Hmood. "Numerical study of heat transfer and fluid flow over circular cylinders in 2D cross flow." Journal of Advanced Research in Applied Sciences and Engineering Technology 30, no. 2 (2023): 216-224. https://doi.org/10.37934/araset.30.2.216224

Liang, Xingxin, Z. Liu, H. Wang, X. Zhou, and X. Zhou. “Hydrodynamic lubrication of partial textured sliding journal bearing based on three-dimensional CFD.” Industrial Lubrication and Tribology 68, (2016): 106-115. https://doi.org/10.1108/ILT-04-2015-0055s

Chauhan, Amit, Rakesh Sehgal, and Rajesh Kumar Sharma. “Thermohydrodynamic analysis of elliptical journal bearing with different grade oils.” Tribology International 43, no. 11 (2010): 1970-1977. https://doi.org/10.1016/j.triboint.2010.03.017

Brito, F. P., A. S. Miranda, J. Bouyer, and M. Fillon. “Experimental investigation of the influence of supply temperature and supply pressure on the performance of a two-axial groove hydrodynamic journal bearing.” Journal of Tribology 129, no. 1 (2007): 98-105. https://doi.org/10.1115/1.2401206

Al-Juhaishi, Lafta Flayih Muhsin, Mas Fawzi Mohd Ali, and Hafidh Hassan Mohammad. "Numerical study on heat transfer enhancement in a curved channel with baffles." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 68, no.2 (2020): 72-83. https://doi.org/10.37934/arfmts.68.2.7283

Ahmad, Mohamad Ali, S. Kasolang, R. S. Dwyer-Joyce, and A. Jumahat, “The effects of oil supply pressure at different groove position on temperature and pressure profile in journal bearing.” Jurnal Teknologi 66, no. 3 (2014): 113-119. https://doi.org/10.11113/jt.v66.2706

Zhou, Yang, and Yuan Ci. "Temperature rise of journal bearing of the high-speed circular arc gear pump." Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 234, no. 8 (2020): 1492-1499. https://doi.org/10.1177/0954406219896818

Taghipour, Yaser, P. Akbarzadeh, F. Moradgholi, and M. Eftekhari Yazdi, “Numerical study of the cavitation effect on plain bearings in constant and variable viscosity states.” Meccanica 56, no. 10 (2021): 2507-2516. https://doi.org/10.1007/s11012-021-01391-7

Abe, K., T. Kondoh, and Y. Nagano. “A new turbulence model for predicting fluid flow and heat transfer in separating and reattaching flows-I. Flow field calculations.” International journal of heat and mass transfer 37, no. 1 (1994): 139-151. https://doi.org/10.1016/0017-9310(94)90168-6

Singla, Amit, A. Kumar, S. Bala, P. Singh, and A. Chauhan. “Thermo-hydrodynamic analysis on temperature profile of circular journal bearing using computational fluid dynamics.” Recent Advances in Engineering and Computational Sciences (RAECS). (2014): 1-6. https://doi.org/10.1109/RAECS.2014.6799595

Hughes, W. F., and F. Osterle. “Temperature effects in journal bearing lubrication.” ASLE Transactions 1, no. 1 (1958): 210-212. https://doi.org/10.1080/05698195808972331

Lin, Qiyin, Z. Wei, Y. Zhang, and N. Wang. “Effects of the slip surface on the tribological performances of high-speed hybrid journal bearings.” Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 230, no. 9 (2016): 1149-1156. https://doi.org/10.1177/1350650116630202