Effects of Operating Conditions on Evaporation Rate and Wall Shear Stress Development in a Micro-gap Heat Sink with Internal Micro-Fins

DOI:

https://doi.org/10.37934/cfdl.14.2.19Keywords:

Micro-gap heat sink, micro-fins, wall heat flux, pumping power, void fractionAbstract

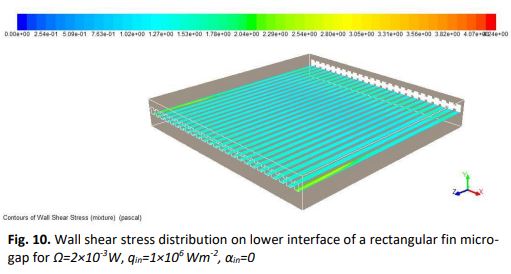

Evaporation in the micro-gap heat sink has a very high heat transfer coefficient. As a result, it is significant for high heat flux management. Heat transfer rate can be enhanced further by including internal micro-fins. However, the pressure drop penalty due to the small gap height and fin surfaces is a major concern. Wall shear stress development is responsible for pressure drop. This paper investigates the effects of operating conditions, e.g., wall heat flux, pumping power, and inlet void fraction, on evaporation rate and wall shear stress development in a micro-gap heat sink with internal micro-fins of rectangular and triangular profiles, while the cross-sectional area (21.8 mm2) is kept constant. R-134a is considered as coolant. Results show that the evaporation rate from per unit volume increases with the increment of wall heat flux and decreases with the enhancement of pumping power. However, after a threshold value of the pumping power (2×10-4 W), the decrement rate falls. Again, the wall shear stress rises with the increasing wall heat flux and pumping power while reduces for escalating inlet void fraction.

Downloads

References

Alam, Tamanna, Poh Seng Lee, Christopher R. Yap, and Liwen Jin. "Experimental investigation of microgap cooling technology for minimizing temperature gradient and mitigating hotspots in electronic devices." In 2011 IEEE 13th Electronics Packaging Technology Conference, pp. 530-535. IEEE, 2011. https://doi.org/10.1109/EPTC.2011.6184478

Alam, Tamanna, Poh Seng Lee, Christopher R. Yap, and Liwen Jin. "A comparative study of flow boiling heat transfer and pressure drop characteristics in microgap and microchannel heat sink and an evaluation of microgap heat sink for hotspot mitigation." International Journal of Heat and Mass Transfer 58, no. 1-2 (2013): 335-347. https://doi.org/10.1016/j.ijheatmasstransfer.2012.11.020

Ahmed, Shugata, Ahmad Faris Ismail, Erwin Sulaeman, and Muhammad Hasibul Hasan. "A critical assessment on evaporative cooling performance of micro finned micro gap for high heat flux applications." ARPN Journal of Engineering and Applied Sciences 11, no. 1 (2016): 313-336.

Ahmed, Shugata, Muhammad Hasibul Hasan, Ahmad Faris Ismail, and Erwin Sulaeman. "Effect of geometrical parameters on boiling heat transfer and pressure drop in micro finned micro gap." ARPN Journal of Engineering and Applied Sciences 11, no. 1 (2016): 297-302.

Ahmed, Shugata, Ahmad Faris Ismail, Erwin Sulaeman, and Muhammad Hasibul Hasan. "Study on turbulent characteristics of flow boiling in a micro gap under the influence of surface roughness and micro fins." ARPN Journal of Engineering and Applied Sciences 11, no. 1 (2016): 410-414.

Ahmed, Shugata, Erwin Sulaeman, Ahmad Faris Ismail, and Muhammad Hasibul Hasan. "Two-Phase Fin-Induced Turbulent Cooling for Electronic Devices Using Heat Pump Associated Micro-Gap Heat Sink." International Journal of Engineering & Technology 3 (2018): 113-122. https://doi.org/10.14419/ijet.v7i3.13.16336

Ahmed, Shugata, Ahmad Faris Ismail, Erwin Sulaeman, and Muhammad Hasibul Hasan. "Experimental Correlation for Flow-boiling Heat Transfer in a Micro-gap Evaporator with Internal Micro-fins." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 54, no. 1 (2019): 1-8.

Ahmed, Shugata. "Study on fin-induced pseudo-turbulent flow boiling characteristics of micro-gap evaporators." (2017).

Alam, Tamanna, Poh Seng Lee, Christopher R. Yap, and Liwen Jin. "Experimental investigation of local flow boiling heat transfer and pressure drop characteristics in microgap channel." International Journal of Multiphase Flow 42 (2012): 164-174. https://doi.org/10.1016/j.ijmultiphaseflow.2012.02.007

Ahmed, Shugata, Ahmad Faris Ismail, Erwin Sulaeman, and Muhammad Hasibul Hasan. "A Comparative Analysis of Flow Boiling in Micro-Gaps with Internal Micro-Fins of Rectangular and Triangular Profiles." International Journal of Applied Engineering Research 11, no. 4 (2016): 2364-2372.

Hirt, Cyril W., and Billy D. Nichols. "Volume of fluid (VOF) method for the dynamics of free boundaries." Journal of computational physics 39, no. 1 (1981): 201-225. https://doi.org/10.1016/0021-9991(81)90145-5

Orszag, S. A., V. Yakhot, and W. S. Flanney. "Renormalization group modeling and turbulence, in international conference on near-wall turbulent flows." In Proceedings of the International Symposium on Mathematical Modeling of Turbulent Flows. Tokyo, Japan. 1995..

Schrage, Robert W. A theoretical study of interphase mass transfer. Columbia University Press, 1953. https://doi.org/10.7312/schr90162

Lee, Wen Ho. "A pressure iteration scheme for two-phase modeling." Los Alamos Scientific Laboratory, Los Alamos, NM, Report No. LA-UR (1979): 79-975.

Wu, H. L., X. F. Peng, P. Ye, and Y. Eric Gong. "Simulation of refrigerant flow boiling in serpentine tubes." International Journal of Heat and Mass Transfer 50, no. 5-6 (2007): 1186-1195. https://doi.org/10.1016/j.ijheatmasstransfer.2006.10.013

De Schepper, Sandra CK, Geraldine J. Heynderickx, and Guy B. Marin. "Modeling the evaporation of a hydrocarbon feedstock in the convection section of a steam cracker." Computers & Chemical Engineering 33, no. 1 (2009): 122-132. https://doi.org/10.1016/j.compchemeng.2008.07.013

Alizadehdakhel, Asghar, Masoud Rahimi, and Ammar Abdulaziz Alsairafi. "CFD modeling of flow and heat transfer in a thermosyphon." International Communications in Heat and Mass Transfer 37, no. 3 (2010): 312-318. https://doi.org/10.1016/j.icheatmasstransfer.2009.09.002