Numerical Simulation of Drying Process within a Novel Rotary Drying Machine for Palm Oil Sludge

DOI:

https://doi.org/10.37934/aram.103.1.3342Keywords:

CFD, meshing, dynamic meshAbstract

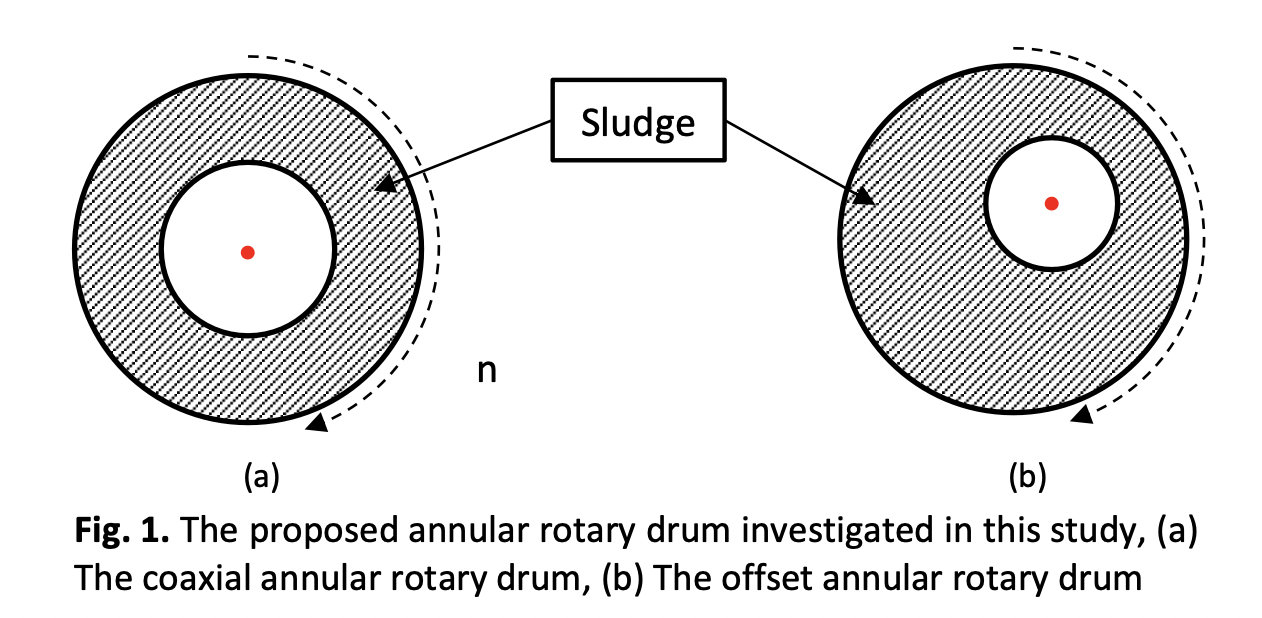

This study investigated how to model a centre-offset annular rotary drum using OpenFOAM and the meshing software GMSH. The diameter of the outer cylinder is 600 mm, diameter of the inner cylinder 200 mm, the centre-offset mm, and rotation rate rpm. When the centre-offset is zero, the quality of mesh is preserved as the drum rotates. Introduction of the offset causes the mesh to be deformed to the point of being unusable as the drum is rotated. The reason was found to be the fixed nodes adjacent to the walls of the outer and inner cylinder. These nodes only respect the motion of the wall they are adjacent to. To circumvent this, we separated the inner volume of the rotary drum to allow the implementation of an OpenFOAM dynamic mesh handling scheme called arbitrary mesh interface (AMI). Implementing AMI allows the quality of the mesh to be kept even when the inner cylinder is rotating under nonzero-offset conditions. This is because AMI permits the sliding of non-conforming meshes next to each other. This preserves the quality of the mesh and secures a reliable and reproducible dynamic mesh motion for the implementation of the drying process in the future.

Downloads