Evaluation of Assembly Time of Motorized Wheel Module for Hospital Bed using Boothroyd-Dewhurst Method

DOI:

https://doi.org/10.37934/aram.108.1.2746Keywords:

Design for assembly, Boothroyd-Dewhurst, motorized wheel, hospital bed, assembly efficiencyAbstract

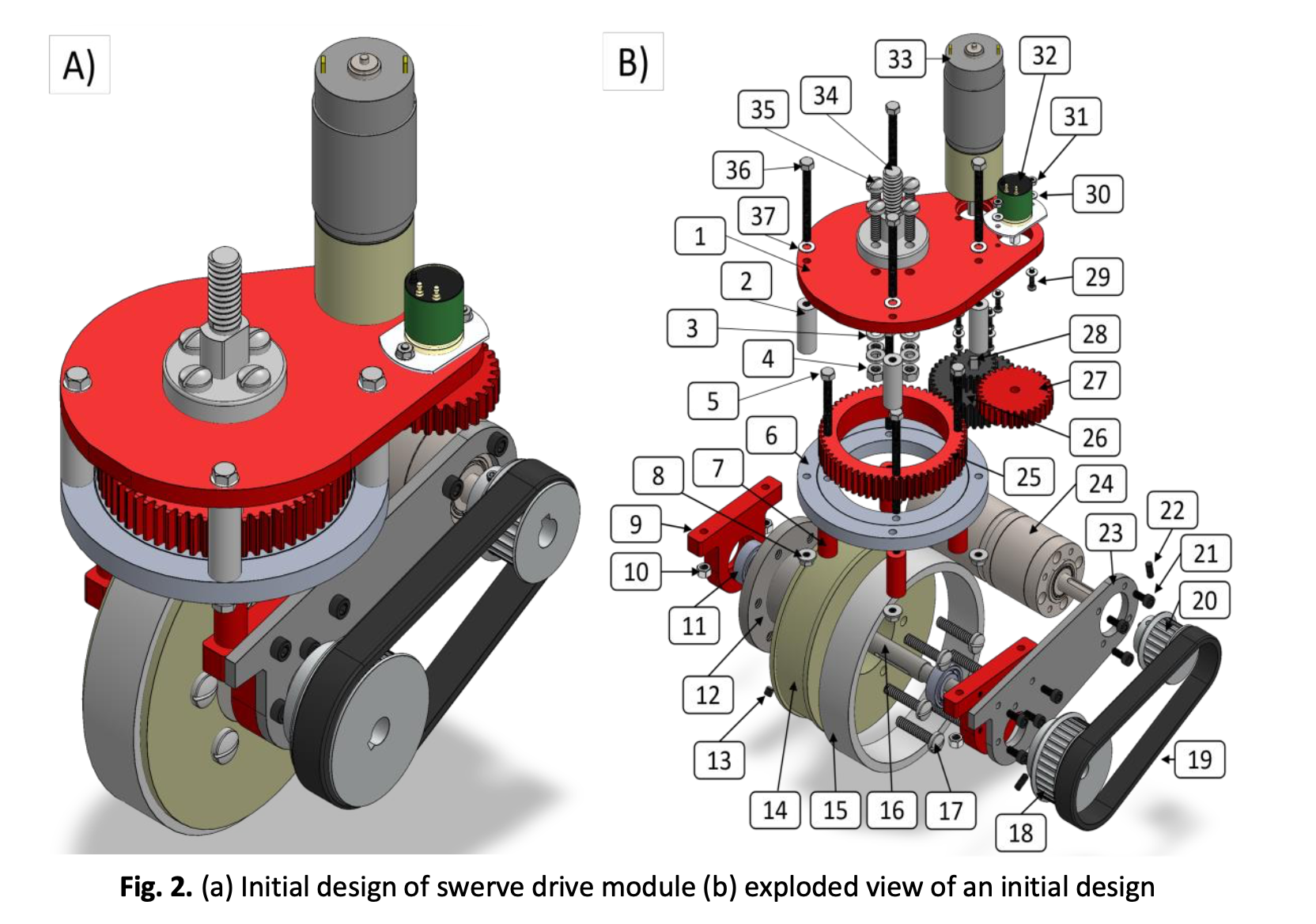

Patient transfer using hospital beds often takes time and is inefficient. This activity also has negative impacts on the health of healthcare workers, such as musculoskeletal injuries. Our group of researchers previously developed a swerve drive motor wheel module, which will be implemented on existing hospital beds. The manual assembly process of the swerve drive wheel module presents its own challenges, especially in terms of manual assembly time. The time required to manually assemble the swerve drive wheel module can be evaluated through the Design for Assembly (DFA) approach using the Boothroyd-Dewhurst method. The previously designed swerve drive wheel module will be compared with an improved design based on this method, where the number of parts to be assembled is minimized. The manual assembly time for the swerve drive wheel module has been shown to decrease after the design improvement. In the previous design, the estimated manual assembly time was 1051.54 seconds, while in the improved design, the manual assembly time was 647.47 seconds, with manual assembly efficiencies of 5% and 9%, respectively. In addition, there is a decrease in the value of the manual assembly complexity index for each design applied to hospital bed legs. In the initial swerve drive module design, the manual assembly complexity index was 16.10, while in the improved swerve drive module design, the index was 15.74 Based on this, a complexity reduction value of 2% was obtained.

Downloads