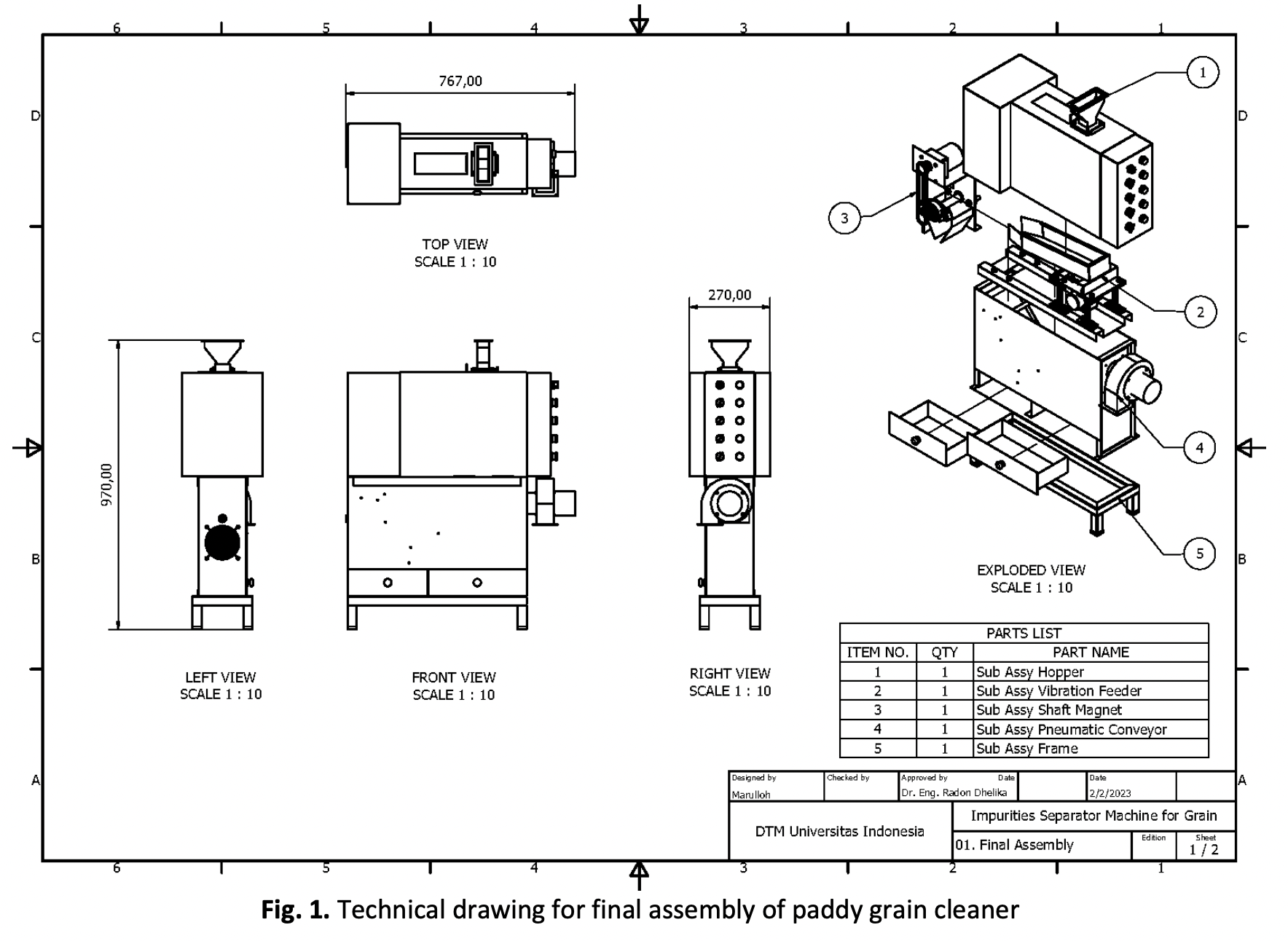

Design and Development of Laboratory-Scale Cleaner for Paddy Grain with Magnetic and Pneumatic Separation

DOI:

https://doi.org/10.37934/aram.108.1.6681Keywords:

Paddy grain, cleanliness, vibration feeder, magnetic, pneumatic, separationAbstract

Food security is a critical concern, and ensuring food quality is just as crucial as ensuring availability and affordability. In Indonesia, paddy is a staple crop with high production and consumption rates. To improve the quality of paddy, particularly in the harvesting and post-harvest processes, mechanization technology has been implemented. One way to assess the quality of harvested paddy is by measuring parameters such as cleanliness and yield loss rate. However, the manual separation process for local varieties is time-consuming and limited in terms of scale. To address this issue, a laboratory-scale paddy grain cleaner was developed based on the physical and aerodynamic characteristics of local paddy varieties. The proposed cleaner includes a hopper, vibration feeder, magnetic separation, pneumatic separation, paddy grain tray, and impurities tray. The vibration feeder prevents grain damage and ensures accurate and consistent seed flow. The feeding system uses a vibration motor with a rotating unbalanced mass within an angle of 30° on both sides and a slope of 7.8° supported by four stainless steel 304 springs with a theoretical displacement maximum value of 0.1593 mm. The feeding rate measurement results are directly proportional to the level of grain moisture content. The paddy grain cleaner has a rotating single-cylinder neodymium magnet for gravel separation and uses axial and centrifugal fans for pneumatic separation of empty grain and low-density impurities. Testing without a centrifugal fan shows better results for lower moisture content of paddy grain with an average separation efficiency, separation loss, and cleaning efficiency of 99.49%, 0.53%, and 99.81%, respectively.

Downloads