Advancements in CNC Machining: Rectangular Boss Feature Validation and Toolpath Precision using STEP AP242 and B-Rep Data Structure

DOI:

https://doi.org/10.37934/aram.113.1.176188Keywords:

CNC Milling Machine, STEP File, GDE approach, PMI DataAbstract

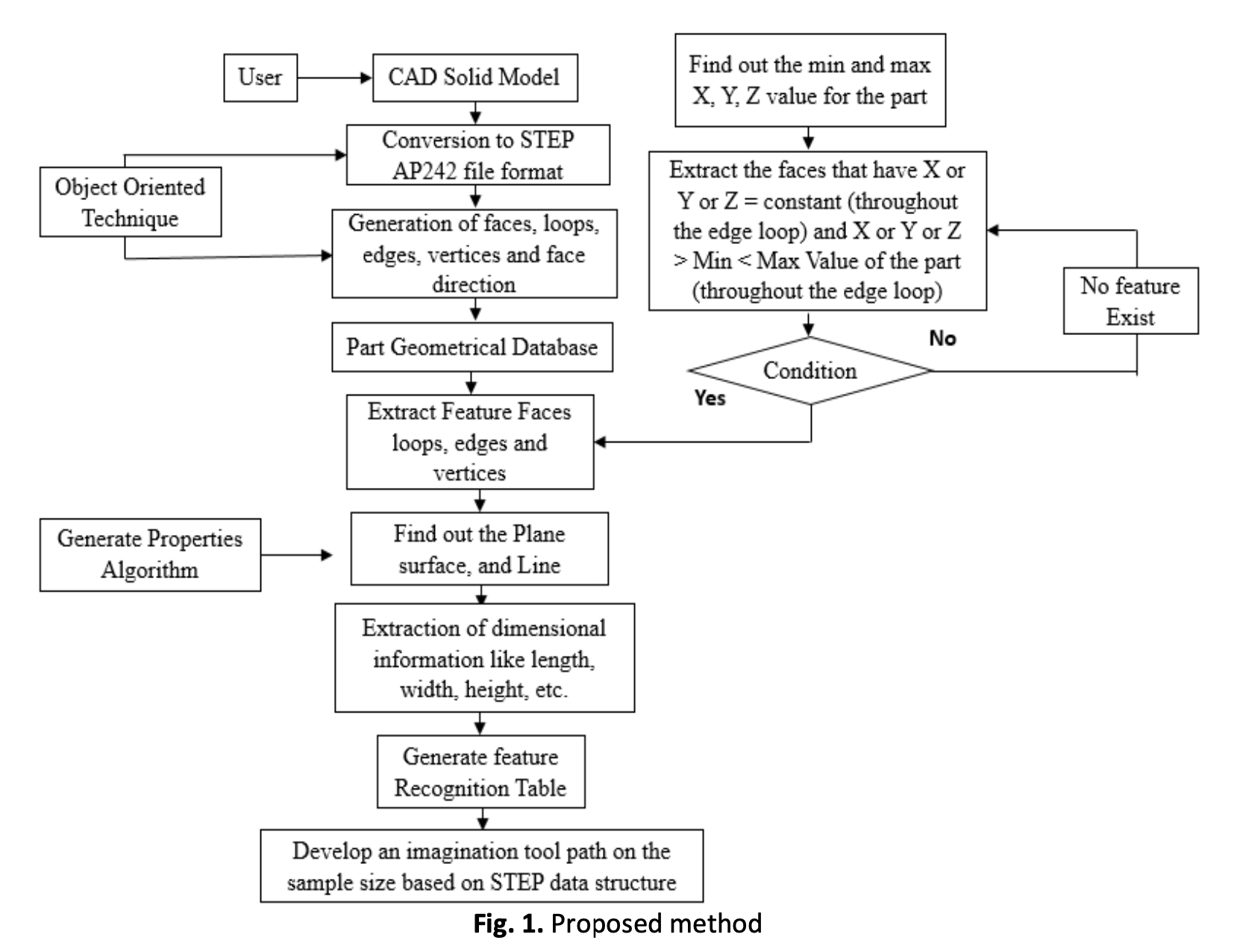

In the context of a CNC machining application, this study proposes an alternate approach for creating toolpaths designed explicitly for machining rectangular bosses utilizing the STEP AP242 file format as a data source. The suggested methodology ensures data accuracy and integrity maintenance by extracting exact geometric information from digital models using Geometric Data Extraction (GDE) tools. The value of the Cartesian multi-point decimal point in the data structure and variations in the reference number of the Cartesian point every time a user accesses and converts to a STEP (AP203) file are two drawbacks of AP203 when compared to the widely utilized AP203 in prior technique studies. This method makes it possible to create G-code efficiently, which is necessary for managing computer numerical control (CNC) machines, by utilizing the power of STEP AP242 and GDE. The process entails finding and separating the rectangular island milling features in the STEP AP242 files, taking out critical geometric characteristics, and creating toolpaths that are optimal for CNC machining. Through this approach, the final G-code instructions are guaranteed to be precisely calibrated to consider every island feature's distinct quality while preserving overall machining efficiency. Several real-world case studies and valuable applications are investigated to confirm the efficacy of the suggested method. The results show significant increases in productivity, decreased waste material, and improved precision of CNC machining, all of which contribute to a more effective and economical production process.

Downloads