Crushing Performances of Kenaf Fibre Reinforce Composite Tubes

DOI:

https://doi.org/10.37934/aram.116.1.130144Keywords:

Crushing performances, kenaf fiber, composite tube, energy absorption, crashworthinessAbstract

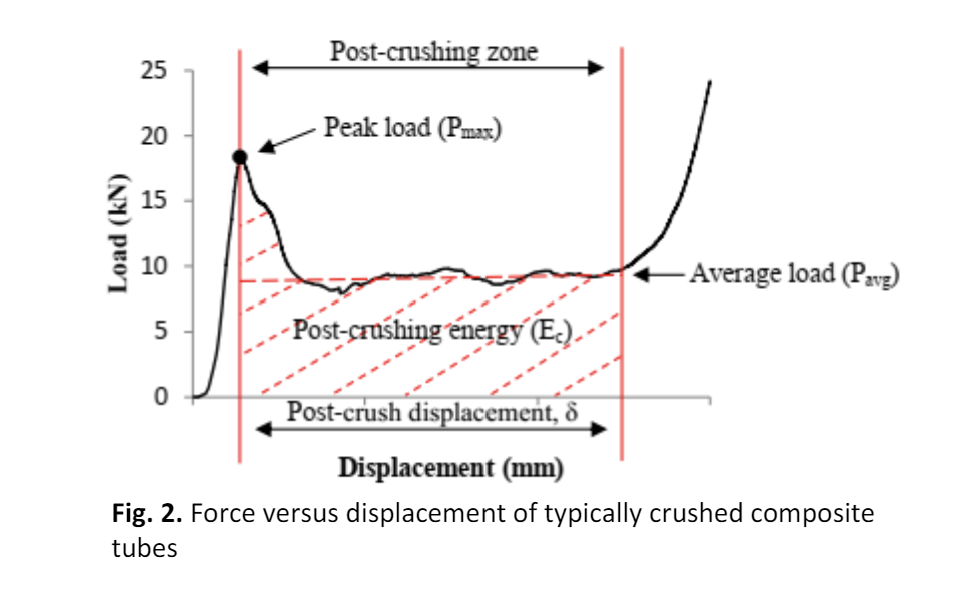

The quest for sustainable and eco-friendly materials has led to a burgeoning interest in natural fibers as reinforcements in composite materials. Kenaf fiber, derived from the Hibiscus cannabinus plant, presents a promising avenue for enhancing the mechanical and energy absorption properties of composite tubes. This study focuses on the fabrication of composite tubes using a combination of kenaf fiber and epoxy resin. The composite tubes were then subjected to compressive testing to evaluate their energy absorption performances. The fabrication process involved the impregnation of kenaf fibre with epoxy resin, followed by winding and curing to form composite tubes. Different configurations of kenaf fiber content were utilized to investigate their impact on the structural integrity and energy absorption capabilities of the tubes. Compressive testing was conducted to assess the energy absorption behaviour under axial loading conditions. The results revealed that the incorporation of kenaf fiber significantly influenced the energy absorption capabilities of the composite tubes. Higher kenaf fiber content demonstrated improved energy absorption performance, showcasing the potential of kenaf fiber as an efficient energy-absorbing reinforcement. The findings of this study offer valuable insights into the use of sustainable and renewable resources, such as kenaf fiber, in enhancing the mechanical and energy absorption properties of composite structures, thereby contributing to the development of eco-friendly and high-performance materials.

Downloads