The Influence of Topology Optimisation and Material Stiffness of Dental Implant on Fatigue Behaviours – A Finite Element Analysis

DOI:

https://doi.org/10.37934/aram.114.1.109124Keywords:

Dental implant, fatigue, finite element analysis, material stiffness, topology optimisationAbstract

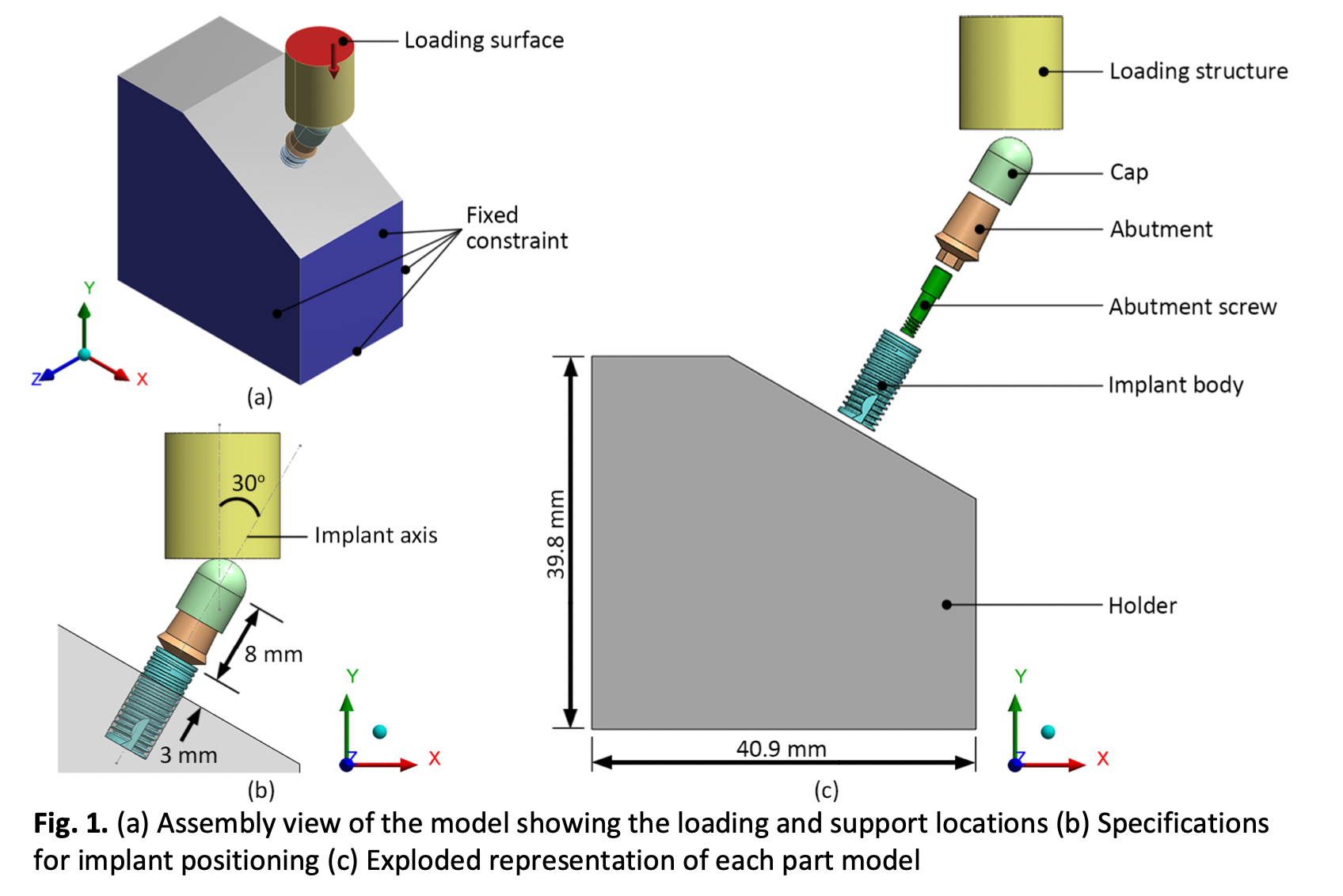

The resilience of a dental implant in restoring occlusion relies on biomechanical stress factors, including implant macrostructures, parafunctional oral behaviours, and the choice of materials. Topology optimisation stands out as a leading approach for enhancing system performance. Different implant designs and materials may have divergent impacts on load distribution at the bone-implant interface. There exists a shortage of published information addressing topologically optimised dental implants and the impact of implant material stiffness, creating a persisting ambiguity on the topic. The novelty of the study lies in the determination of excess material distribution within a dental implant and the influence of different implant stiffnesses through computational fatigue analysis. This study aimed to evaluate the fatigue characteristics of regular and topologically optimised dental implant configurations across various implant materials, employing three-dimensional finite element analysis. Geometric models were developed following ISO 14801 standards using SolidWorks 2020, and subsequently, analysed in ANSYS 18.1. Each implant design (regular, optimised design 1, and optimised design 2) was subjected to three different material stiffnesses indicated by cpTi, Ti-6Al-4V, and zirconia. The model was exerted by a 200-N inclined load. Compared to the regular implant, the topologically optimised implants exhibited a decrease in implant stress ranging from approximately 3.4% to 11.9%. However, the regular design yielded a longer fatigue life, surpassing that of the optimised designs by about 33.8% to 75.9%. Concerning safety factors, the optimised implants displayed safety factor levels that were nearly 3.5% to 13.5% greater than those of the regular implant. Among all the materials, the implant with higher stiffness was found to be advantageous, as it resulted in reduced implant stress, extended fatigue life, and increased safety factor compared to the less stiff implant, regardless of the implant designs.

Downloads