Quantifying the Impact of Drilling Parameters on Temperature Elevation within Bone during the Process of Implant Site Preparation

DOI:

https://doi.org/10.37934/aram.116.1.112Keywords:

Orthopaedics, bone drilling, thermal bone damage, ANOVA analysis, optimizing drilling conditionsAbstract

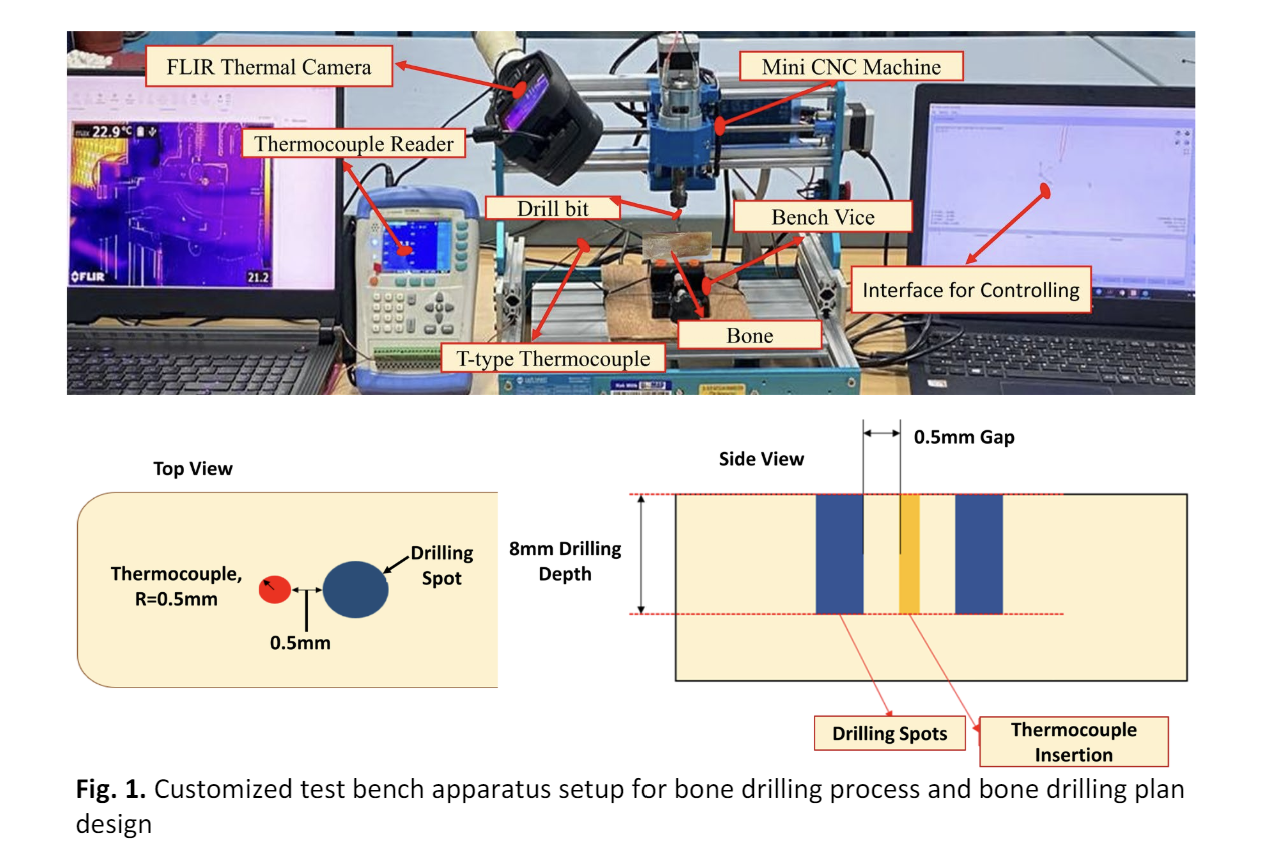

This study aimed to elucidate the influences of several drilling parameters on bone temperature during drilling, as excessive heat generation can cause thermal bone damage and affect post-surgery recovery. In vitro drilling tests were conducted on bovine femoral shaft cortical bone specimens. The parameters considered included tool rotational speed (s), feed rate (f), tool diameter (d), and drill tip angles of 118° and 135°. Drilling temperatures were studied across a range of 800–2000 rpm rotational speeds, 20–40 mm/min feed rates, and 2–4 mm drill diameters. A predictive statistical model was constructed using the response surface methodology (RSM). Analysis of variance (ANOVA) at a 95% confidence level (α = 0.05) revealed that rotational speed significantly impacted temperature increase, contributing to 59.74% of observed temperature rises. Drill diameter accounted for 16.21% of temperature variations, while feed rate contributed to 10.04% of the temperature rises. The study provides valuable insights into the predominant factors affecting bone temperature during drilling. Understanding these parameters and their interplay is pivotal for optimizing drilling conditions and minimizing potential thermal damage to bones.

Downloads