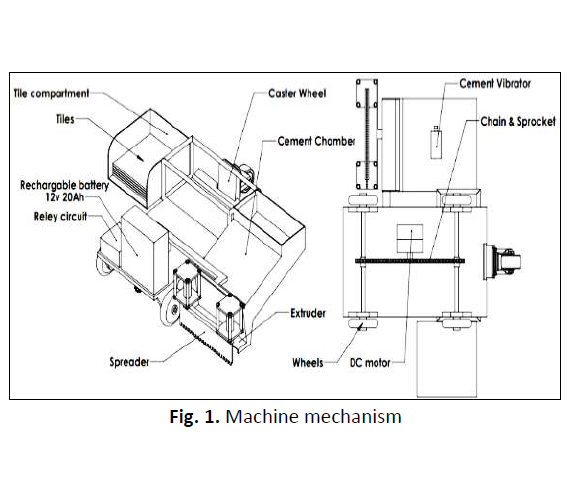

Development of Semi-Automated Thinset Mortar Scraper Machine with Tile Compartment

DOI:

https://doi.org/10.37934/araset.64.2.104113Keywords:

Cement scraper, cement extruder, cement filler, cement machine, tile cement scraperAbstract

In the construction field in industry, manual labor is highly demanded in all aspects of the work; prior to that, the manual ability to place tiles was required, which takes much longer than spreading cement, aligning, and adjusting the size of tiles. Because there will be manual scraping of cement mortar on the floor before tile installation, there will be a significant demand for labor, and aside from that, the cost of construction or project work is likely to increase. The manual labor skill will reflect the quality of the work in the manual scraping process. The solution to these problems is simply semi-automating the procedure; it will save time and money and result in a quality scraping of cement mortar. The semi-automated scraper machine can scrape the floor semi-automatically. It will create a square scraped output that is best for laying the tiles to avoid damage and ensure longevity. In a bucket of 80% cement and 20% can fully operate by addition, the average length test is 84.03 inches with the accuracy tiles of 70.213 inches that can fully operate the 83.56% length. At least 9 to 11 tiles to install, particularly the edge of the cement surface length, to install an 8x8” tile at a machine efficiency power output of 49.32%. Due to the fast pace and less labor required, it will save both cost and time, which helps reduce the total cost as total time consumed is a factor in the growth and success of the country.

Downloads