Milling Features Recognition Methodology of Rectangular Fillet Blind Pocket for Universal Data Structure

DOI:

https://doi.org/10.37934/araset.30.3.5768Keywords:

CNC Milling machine, STEP File, geometric entitiesAbstract

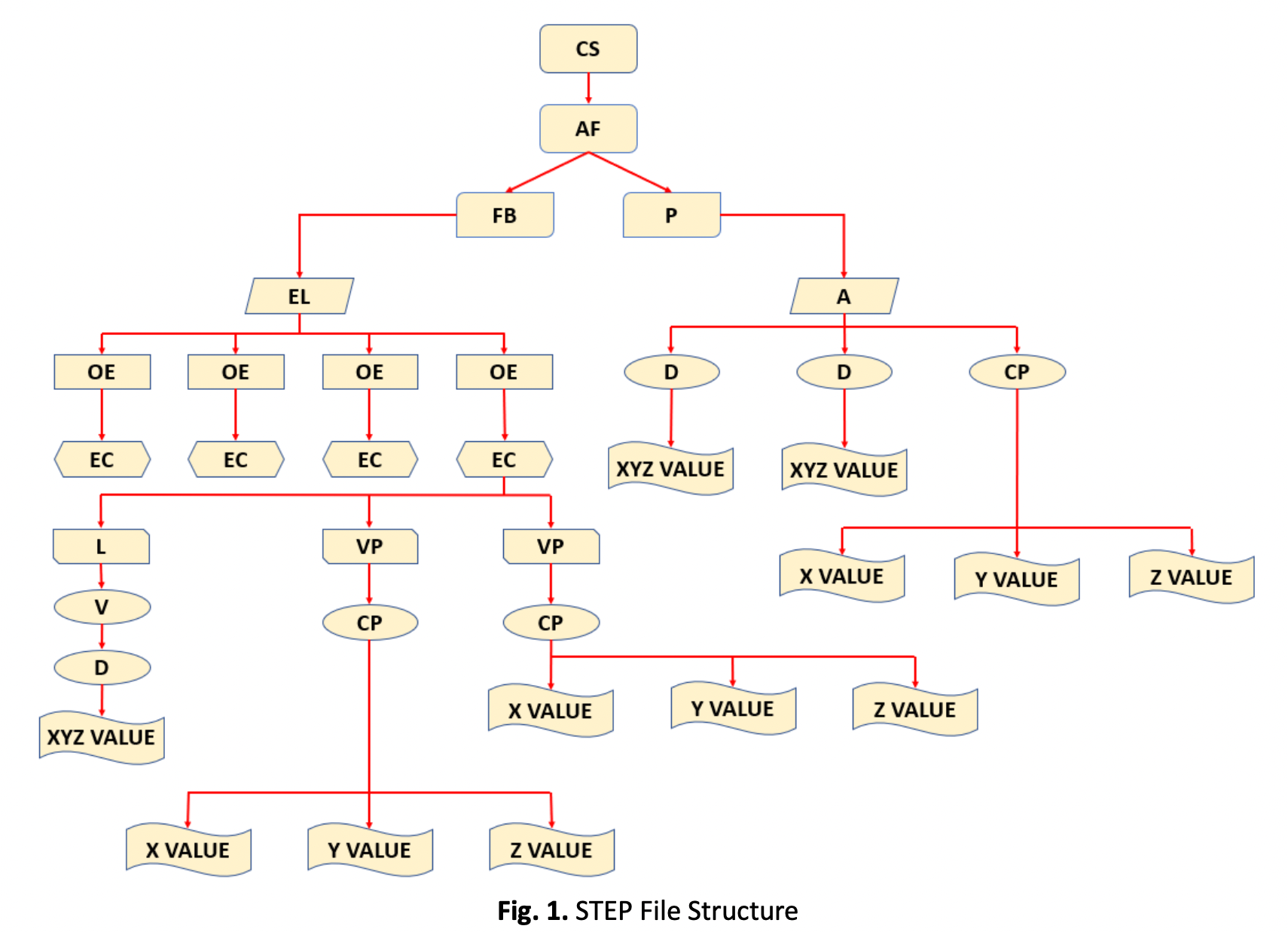

Various studies have focused on developing an interface system that could integrate the machining process with CNC (Computer Numerical Control) machine tools by producing tool paths using STEP (Standard for the Exchange of Product model data) file as an input function. Studies to recognize features in STEP file by encoding the data of geometric entities of a CAD (Computer-Aided Design) design has been done by many researchers. However, they only focus on Cutter Location (CL) which eventually describes the machining profile in the x and y planes without considering the depth of the machining feature in the z-axis. Identifying and recognizing machining features in the STEP file is important since STEP is a platform for converting industry-standard CAD systems and software data models. The aim of this paper is to identify profiles of geometric machining features for rectangular fillet blind pockets using the Geometric Data Extraction (GDE) approach. Three cases have been carried out namely single rectangular fillet blind pocket, double rectangular fillet blind pocket and triple rectangular fillet blind pocket. The results were verified by manual graph plotting and automatic graph plotting using CPM 3D Plotter.

Downloads