The Effects of Fly Ash and Bottom Ash on the Properties of Aerated Concrete under Density-Based Mix Design

DOI:

https://doi.org/10.37934/araset.34.2.99116Keywords:

Fly ash, bottom ash, aerated concrete, densityAbstract

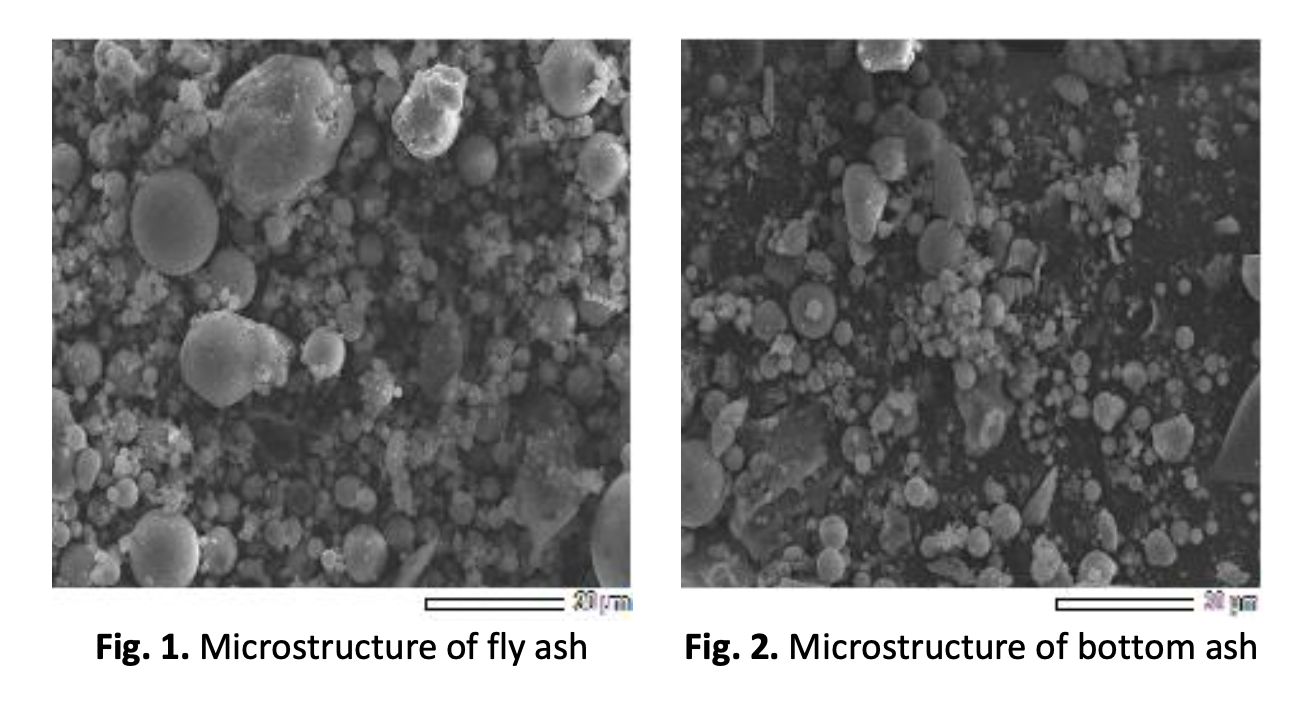

Lightweight concrete has the main characteristic of a lower density value than normal concrete, which ranges from 1400 to 1850 kg/m3 (ACI 213R) [1]. While density values generally show a decreasing trend along with decreasing mechanical properties. This type of lightweight concrete still needs to be improved in its application to elements that function but do not withstand loads (non-structural) due to its low mechanical properties. The main objective of producing lightweight concrete is its density. In contrast, another objective is the mechanical properties related to the use of lightweight concrete as a non-structural or structural material. Thus, physical properties in the form of density and mechanical properties in the form of compressive strength are important parameters in producing lightweight concrete. The mix method used in lightweight concrete is different from conventional concrete. The foaming agent used in manufacturing lightweight concrete will result in compressive strength and density results that are different from conventional concrete. In this study, lightweight concrete was made using the aerated technique: a foaming agent in aluminum powder and comprises cement, sand, fly ash, bottom ash, water, and superplasticizer. Fly ash as a substitute for cement and bottom ash as a substitute for sand with percentages of 0%, 15%, and 30%, and of 0%, 25%, and 50%, respectively. Those materials were aimed to optimize the composition of aerated concrete. The mix design was conducted with a density-based mix design of density targets of 1000 kg/m3, 1200 kg/m3, 1600 kg/m3, and 1800 kg/m3. The parameters used to assess the research results were slump value, setting time, density, compressive strength, and water absorption. While the consistency and stability values were found to be an indicator of the achievement of this density-based mix design. The performance indexes which demonstrate the attainment of compressive strength and predicted density in the aerated concrete, show that the mix designs meet the requirements of non-structural lightweight concrete. The mix of ingredients, particularly fly ash and bottom ash, has a considerable influence on the relationship between compressive strength and density in aerated concrete.

Downloads