Material Characterizations of the Polymers Reinforced with Recycled Flexible Plastic Blends as Filament for 3D Printing

DOI:

https://doi.org/10.37934/araset.37.1.115Keywords:

Addictive manufacturing, Filament blends, High-density polyethylene, Polypropylene, Recycled flexible plasticAbstract

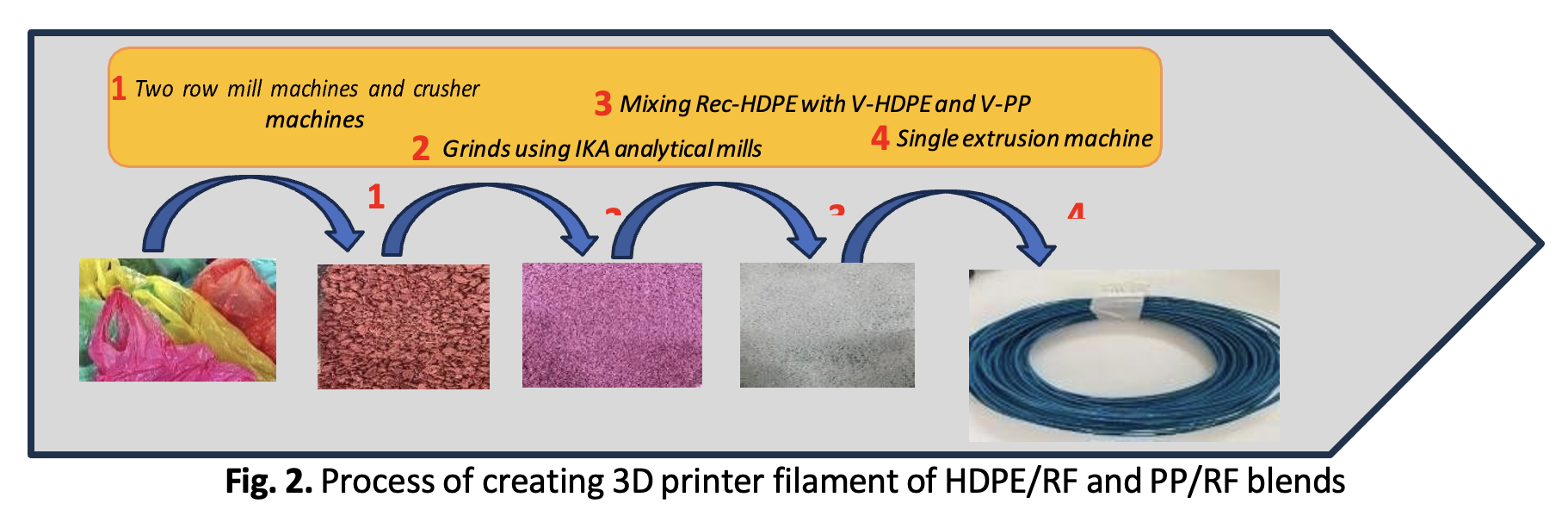

The high consumption of single-use plastics and the low recycling rates have seriously polluted the soil and ocean environments. Thermoplastic materials from recycling can be used to make filaments for 3D printing. This study is focused on preparing, characterizing, and comparing the polymers reinforced with recycled flexible plastic blends to be used as a filament in additive manufacturing. In this regard, two types of polymers were used to create the filament: High-Density Polyethylene (HDPE) and Polypropylene (PP), which were mixed with recycled flexible plastic (RF). The mixture was initially used to create filament by using a single extrusion machine, with various ratios of virgin HDPE and PP to recycled flexible plastic (in weight%) at temperatures of 190°C and 230°C. Then, the filament blends were characterized using infrared (IR) spectroscopy, thermogravimetric analysis (TGA), and field emission scanning electron microscopy (FESEM). TGA analyses revealed that RF can increase the thermal stability of V- HDPE and V-PP upon blending, and HDPE/RF blends show a higher decomposition temperature than PP/RF. FESEM indicated that adding 30% RF is the best percentage for both polymer blends where the structure appears ductile. It can be concluded that the HDPE 70% blend is suitable for 3D printer filament as it showed the best decomposition temperature and the ductility of the fracture structure, which meet the requirements for 3D printer filament.

Downloads