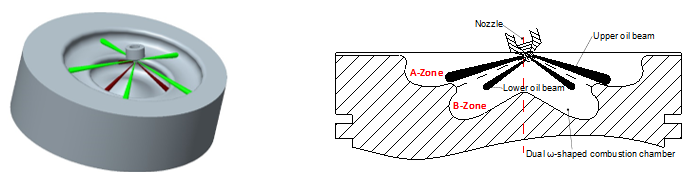

Numerical Simulation on the Spray Angle of the Dual-layer Hole Nozzle in a Partition Combustion System of the Diesel Engine

DOI:

https://doi.org/10.37934/arnht.19.1.2942Keywords:

Double ω-shaped combustion chamber, Double-layer hole nozzle, Spray angle, Numerical simulationAbstract

To study the effect of the spray angles of the dual-layer hole nozzle on the combustion and emissions performance in the partition combustion system, the in-cylinder spray, mixture formation and combustion processes of the new combustion system were simulated and investigated using AVL FIRE software. The results show that, compared with the variation of the lower-layer spray angles, the change of the upper-layer spray angles has a great influence on the instantaneous heat release rate. The increasing spray angles of the lower-layer holes lead to reduced peak values of the heat release rate in the cylinder. In all the spray angle cases, the first fire area of the cylinder is in the B zone of the combustion chamber. Compared with lower-layer spray angle, the upper-layer spray angle has a greater impact on the airflow disturbance in the combustion chamber. Appropriately increasing the upper-layer spray angle facilitates the mixing of fuel and air in the combustion chamber and reduces the unburnt fuel equivalence ratio. When the spray angles of the upper- and lower-layer holes are 157° and 112°, respectively, the combustion indicates power has the largest value of 12.18 kW. At the same time, the Soot emission is also the smallest, with a value of 0.52 g/kW·h.

Downloads

References

Temizer, Ilker, and Omer Cihan. "An experimental investigation of new chamber geometry on the combustion characteristics, performance and emissions in a light-duty diesel engine." Fuel 345 (2023): 128160. https://doi.org/10.1016/j.fuel.2023.128160

Agarwal, Avinash Kumar, Akhilendra Pratap Singh, and Rakesh Kumar Maurya. "Evolution, challenges and path forward for low temperature combustion engines." Progress in energy and combustion science 61 (2017): 1-56. https://doi.org/10.1016/j.pecs.2017.02.001

Maricq, M. Matti. "Engine, aftertreatment, fuel quality and non-tailpipe achievements to lower gasoline vehicle PM emissions: Literature review and future prospects." Science of The Total Environment 866 (2023): 161225. https://doi.org/10.1016/j.scitotenv.2022.161225

Deng, Xiwen, Jilin Lei, Jun Wen, Zhigao Wen, and Lizhong Shen. "Influences of piston structural parameters on heat transfer and temperature field of diesel engine piston." Transactions of the Chinese Society of Agricultural Engineering 33, no. 10 (2017): 102-108. https://doi.org/10.11975/j.issn.1002-6819.2017.10.013

Moses, Larry Sundaran, Md Tasyrif Abdul Rahman, Abdul Hamid Adom, Mohd Ridzuan Mohd Jamir, Mohd Al Hafiz Mohd Nawi, and Mohd Hafif Basha. "An Analysis of The Material and Design of an Exhaust Manifold for A Single-Cylinder Internal Combustion Engine." Journal of Advanced Research in Applied Sciences and Engineering Technology 30, no. 2 (2023): 163-175. https://doi.org/10.37934/araset.30.2.163175

Qian, Yejian, Zhen Gong, Xiaowei Shao, Changfa Tao, and Yuan Zhuang. "Numerical study of the effect of combustion chamber structure on scavenging process in a boosted GDI engine." Energy 168 (2019): 9-29. https://doi.org/10.1016/j.energy.2018.11.080

Raman, Venkat, and Malik Hassanaly. "Emerging trends in numerical simulations of combustion systems." Proceedings of the Combustion Institute 37, no. 2 (2019): 2073-2089. https://doi.org/10.1016/j.proci.2018.07.121

Pathak, Bhavesh, Asfakahemad Shekh, Nikul Patel, and Vimal Patel. "Review Analysis on CFD Techniques and Numerical Methods for IC Engines Fueled with Diesel and Biofuels." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 110, no. 1 (2023): 40-62. https://doi.org/10.37934/arfmts.110.1.4062.

Zhou, Xinyi, Tie Li, Yijie Wei, and Sichen Wu. "Scaling spray combustion processes in marine low-speed diesel engines." Fuel 258 (2019): 116133. https://doi.org/10.1016/j.fuel.2019.116133

Calik, Alper Tolga, Ozgur Oguz Taskiran, and Rafig Mehdiyev. "Numerical investigation of twin swirl application in diesel engine combustion." Fuel 224 (2018): 101-110. https://doi.org/10.1016/j.fuel.2018.03.049

Zhang, Zhicheng, Shengli Wei, Jie Chen, Xianyin Leng, Shaobang Zhang, and Shidong Ni. "Numerical Study of the Mixture Formation and Combustion Characteristics in Gasoline Direct Injection Engines with Conical Spray." Arabian Journal for Science and Engineering 48, no. 9 (2023): 11525-11535. https://doi.org/10.1007/s13369-022-07492-z

FIRE, AVL. "Users manual." AVL List GmbH, Graz (Austria). Version (2019).

Doppalapudi, Arun Teja, A. K. Azad, and M. M. K. Khan. "Combustion chamber modifications to improve diesel engine performance and reduce emissions: A review." Renewable and Sustainable Energy Reviews 152 (2021): 111683. https://doi.org/10.1016/j.rser.2021.111683

Wei, Sheng Li, Hong Kun Lu, and Xian Yin Leng. "Numerical simulation of impinging convexity on partition combustion system performance of diesel engines." Journal of Jiangsu University: Natural Science Editions 36, no. 5 (2015): 509-515. https://doi.org/10.3969/j.issn.1671-7775.2015.05.003

Wei, Shengli, Zhiqing Yu, Zhilei Song, Fan Yang, and Chengcheng Wu. "Effect of conical spray and multi-hole spray on gasoline engine mixture formation and combustion performance based on different injection strategies." Journal of Energy Resources Technology 143, no. 6 (2021): 062305. https://doi.org/10.1115/1.4048595

Feng, Shiquan, Shenglong Zhang, Hongmei Zhang, and Jidong Shi. "Effect of nozzle geometry on combustion of a diesel-methanol dual-fuel direct injection engine." Fuel 357 (2024): 129734. https://doi.org/10.1016/j.fuel.2023.129734

Zhou, Haiqin, Xiangrong Li, Yanlin Chen, Yuning Kang, Dong Liu, and Fushui Liu. "The effect of spray angle on the combustion and emission performance of a separated swirl combustion system in a diesel engine." Energy 190 (2020): 116481. https://doi.org/10.1016/j.energy.2019.116481

Guo, Qiang, Jie Liu, Binyang Wu, and Yize Liu. "The multi-parameter optimization of injections on double-layer diesel engines based on genetic algorithm." Fuel 339 (2023): 126920. https://doi.org/10.1016/j.fuel.2022.126920

WEI, Sheng-li, Hong-kun LU, Xian-yin LENG, Yu LIANG, Liang CHEN, and Fei-hu WANG. "Experimental Research on Combustion System with Double ω Combustion Chamber for ZS1100M Diesel Engine." Acta Armamentarii 37, no. 1 (2016): 17. https://doi.org/10.3969/j.issn.1000-1093.2016.01.003

Lešnik, Luka, Jurij Iljaž, Aleš Hribernik, and Breda Kegl. "Numerical and experimental study of combustion, performance and emission characteristics of a heavy-duty DI diesel engine running on diesel, biodiesel and their blends." Energy Conversion and Management 81 (2014): 534-546. https://doi.org/10.1016/j.enconman.2014.02.039

Dayal, Akash, Manish Shrivastava, Rajiv Upadhyaya, and Lakhbir Singh Brar. "Numerical study using detailed chemistry combustion comparing effects of wall heat transfer models for compression ignition diesel engine." SN Applied Sciences 1 (2019): 1-6. https://doi.org/10.1007/s42452-019-1033-z

Koten, Hasan. "Investigation of diesel engine performance and emissions by multi-dimensional modeling." International Journal of Automotive Engineering and Technologies 7, no. 2 (2018): 76-87. https://doi.org/10.18245/ijaet.458898

WEI, Sheng-li, Fei-hu WANG, Huan CHEN, and Xian-yin LENG. "Research on Effect of Nozzle Hole Distribution on Performance of Combustion System with Double ω CombustionChamber for Diesel Engine." Acta Armamentarii 36, no. 1 (2015): 33. https://doi.org/10.3969/j.issn.1000-1093.2015.01.005

Jena, Ashutosh, Akhilendra Pratap Singh, and Avinash Kumar Agarwal. "Optical and computational investigations of the effect of Spray-Swirl interactions on autoignition and soot formation in a compression ignition engine fuelled by Diesel, dieseline and diesohol." Applied Energy 324 (2022): 119677. https://doi.org/10.1016/j.apenergy.2022.119677