Influence of Adhesive Curing Temperature and Geometrical Parameters on Composite Patch Repair of Cracked Structures

DOI:

https://doi.org/10.37934/arfmts.119.1.112Keywords:

Crack repair, stress intensity factor, finite element analysisAbstract

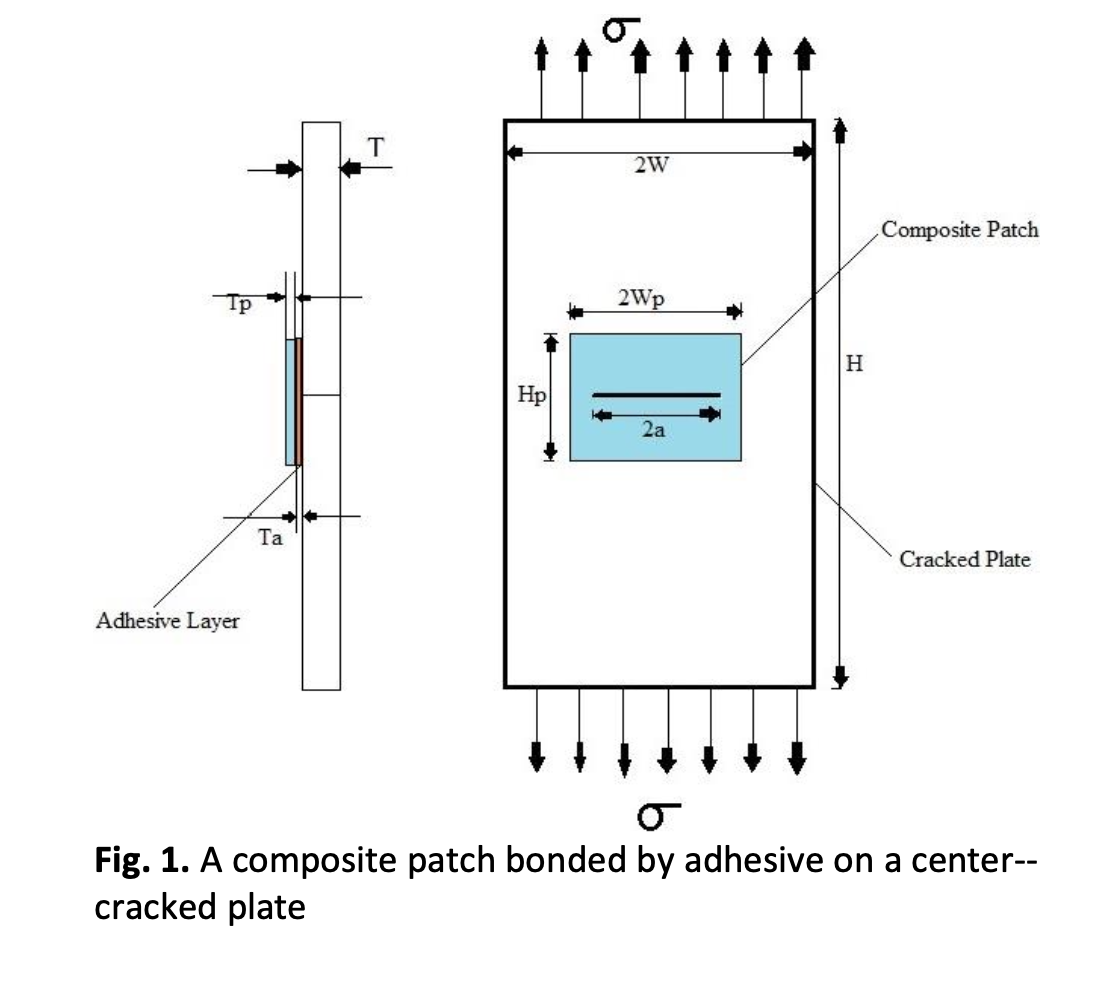

Revitalizing aircraft structural components marred by damage is imperative to enhance their operational lifespan, obviating the need for wholesale replacement of parts or even the entire airframe. The application of composite patches for mending fractured structures contributes significantly to prolonging their serviceability. However, this strategy often mandates curing the adhesive at temperatures surpassing ambient conditions. Hence, the present investigation centers on the reparation of a cracked plate via a composite patch under conditions of thermo-mechanical loading. The study also delves into the repercussions of thermal stresses on the Stress Intensity Factor (SIF), engendered by elevated curing temperatures. By executing Finite Element Analysis (FEA), the SIF at the crack tip was computed, and a parametric examination was executed to scrutinize the influence of assorted parameters such as the thickness of the patch and adhesive on SIF, leveraging the ANSYS tool. Notably, the existence of a composite patch resulted in a substantial reduction of SIF, with noteworthy SIF alterations arising from parameter variations. Elevation in SIF, prompted by thermal stresses due to adhesive curing, was found to manifest markedly, a predicament that can be mitigated by effecting adhesive curing at ambient temperatures.

Downloads