Physical Properties of New Formulation of Hybrid Nanofluid-based Minimum Quantity Lubrication (MQL) from Modified Jatropha Oil as Metalworking Fluid

DOI:

https://doi.org/10.37934/arfmts.101.1.110Keywords:

Modified jatropha oil, hybrid nanofluid, hBN, WS2, TiO2Abstract

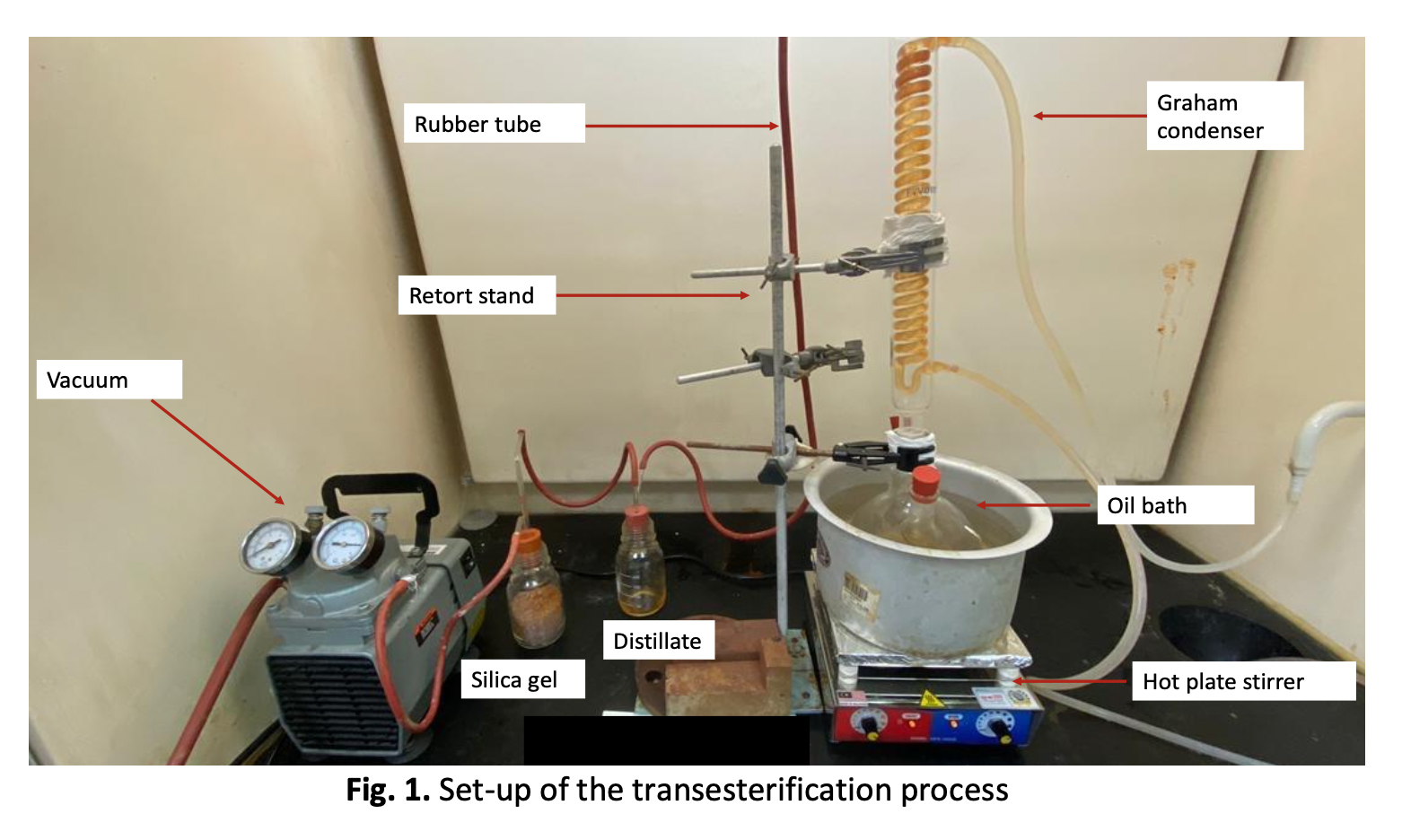

As a metalworking fluid, vegetable-based crude jatropha oil (CJO) was used in place of petroleum-based oil. The use of petroleum-oil-based metalworking fluids poses significant environmental and health concerns. Furthermore, it has a large amount of free fatty acid (FFA), promoting physical damage. This research targets to substantially evaluate the modified jatropha nanofluids formulation as a metalworking fluid for machining processes. CJO was chemically altered using the esterification and transesterification processes to produce modified jatropha oil (MJO). To make the nanofluids, MJO was mixed with nanoparticles of Hexagonal Boron Nitride (hBN) + Tungsten Disulfide (WS2) and Hexagonal Boron Nitride (hBN) + Titanium Dioxide (TiO2) at a concentration of 0.025 wt.%. The viscosity and acid value of MJO nanofluids were assessed using ASTM standards and compared to a synthetic ester (SE). All the data indicates that the physical attributes improved throughout storage. It is possible to conclude that MJOhw (MJO + 0.025 wt.% hBN + WS2) has the ability as a long-term metalworking fluid for the machining operation. According to the experiment results, MJOhw surpasses non-additive MJO in terms of kinematic viscosity by 5.91% at 40 °C and 15.6% at 100 °C. During a one-month duration of storage time, MJOhw also improve viscosity index (319) by 18.15%. Furthermore, MJOhw has an acid value ranging from 0.34 to 0.58 mg NaOH/g. Finally, the inclusion of additives aids MJO in improving its qualities by 31.1% reduction in acid value and MJOhw demonstrates outstanding lubricating properties across all samples.

Downloads